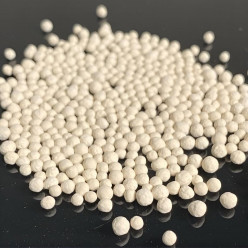

Molecular sieve 3A, 2.0-3.5 mm for dehydration of alcohol

Brand:

BTS EngineeringCharacteristics

Producer:

BTS Engineering

Zeolite (Anhydrous Solids Content, 1h/800°С), %:

80 ± 3

Packaging:

Plastic bags: 25kg/1m pallet; Metal barrels: 140 kg; Big bags: 0.5 МТ. or 1 mt.

Binder, %:

18 ± 2

Nozzle type:

Molecular Sieve

Bulk density, g/l:

730 ± 70

Static water adsorption, %:

22 ± 3 (25°С, RH=55%, 24g)

See all

Categories

Favorite

Compare

Products from the same category

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Molecular sieve 3A, 2.0-3.5 mm for dehydration of alcohol

Producer | BTS Engineering |

Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

Packaging | Plastic bags: 25kg/1m pallet; Metal barrels: 140 kg; Big bags: 0.5 МТ. or 1 mt. |

Binder, % | 18 ± 2 |

Nozzle type | Molecular Sieve |

Bulk density, g/l | 730 ± 70 |

Static water adsorption, % | 22 ± 3 (25°С, RH=55%, 24g) |

Diameter, mm | 2.0-3.5 |

Water content, % | 2 ± 1 |

Hardness, N | 40 ± 20 |

Country of Origin | Switzerland |

Application | дистиляции, дегидратации, абсорбера, десорбера, очистки газов, декарбонизатора, насадочных колонн, ректификации |

Description Molecular sieve 3A, 2.0-3.5 mm for dehydration of alcohol

The separation of water and ethanol is particularly challenging due to the formation of an azeotrope at 95 % v/v ethanol. It is impossible to achieve further separation of the components by conventional means at this concentration of ethanol and water at atmospheric pressure. This is because the composition of the components in the liquid phase and the gas phase is equivalent. There are several ways around this limitation. However, the focus here is on a physical separation technique that uses molecular sieves. Molecular sieves are synthetic balls with fine pores. The pores are large enough to allow water molecules to pass through, but small enough to restrict the flow of ethanol into the beads. The water saturates the beads and the dehydrated ethanol passes through the system. High temperatures and pressure fluctuations evaporate the water in the balls. The balls are reused for further separation. This technique is a physical separation, meaning that the azeotropic component does not limit the ability to remove water. With the development of adsorption processes and the invention of molecular sieves, the pressure-swing adsorption (PSA) process has completely replaced azeotropic and extraction distillation for ethanol dehydration due to performance, cost and environmental reasons. PSA is now the technology of choice for ethanol dehydration for both small and large scale plants. In the ethanol PSA process, water is removed using a suitably sized molecular sieve adsorbent. The adsorption of ethanol on zeolite 3A is usually neglected in ethanol dehydration studies. Nowadays, ethanol dehydration processes with two and three layers of PSA are common in industry. PSA technology is the preferred and industrially established method for separating water-ethanol mixtures for ethanol production. Adsorption technologies are an attractive solution for the separation of bioprocessing end products due to the flexibility in the choice of adsorbents, operating conditions, process design and cycles.

Molecular sieve 3A, 2.0-3.5 mm for dehydration of alcohol reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.