Ceramic Pall Ring, 50x50x5mm, VFF

Brand:

VFFCharacteristics

Producer:

VFF

Pour density, kg/m3:

550

Specific surface area, m2/m3:

120

Dimensions, mm:

50x50x5

Nozzle type:

Pall Ring

Thickness mm:

5

Void factor, %:

78

See all

Categories

Favorite

Compare

Products from the same category

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Ceramic Pall Ring, 50x50x5mm, VFF

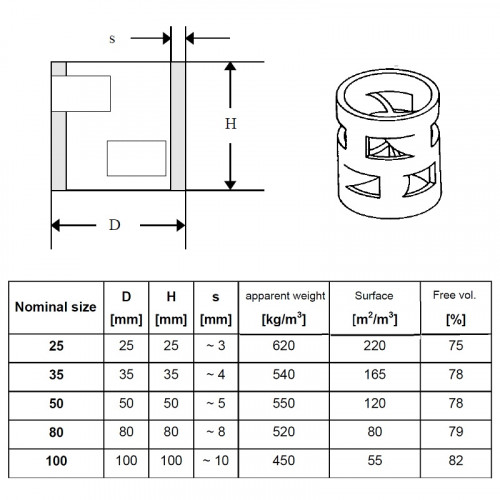

Producer | VFF |

Pour density, kg/m3 | 550 |

Specific surface area, m2/m3 | 120 |

Dimensions, mm | 50x50x5 |

Nozzle type | Pall Ring |

Thickness mm | 5 |

Void factor, % | 78 |

Diameter, mm | 50 |

Material | Ceramics |

Country of Origin | Germany |

Application | дистиляции, дегидратации, абсорбера, десорбера, очистки газов, декарбонизатора, насадочных колонн, сатурации воды, ректификации |

Analogue for | AMACS, Koch-Glitsch, Christy Catalytics, НКС DOLSIN, Ultimo Engineers, Munters, MACH Engineering LLC, Pall Ring Company, MTE |

Description Ceramic Pall Ring, 50x50x5mm, VFF

Ceramic Pall Ring by German manufacturer VFF is a type of classic irregular nozzle developed on the basis of the Raschig ring. Usually, the nozzle has two holes with bends inside the cylinder wall. Each hole has five tongues that are bent to the axis of the ring. The ceramic Pall ring is completely identical in shape to the metal and plastic Pall rings. However, the number of holes and bends can vary depending on the height and diameter.

In general, the open surface of the nozzle should occupy 30% of the total cylindrical wall area. This design helps vapour and liquid to pass through the holes with ease, allowing full use of the inner ring surface for vapour and liquid separation. This also improves separation efficiency.

An important advantage of ceramic rings is their wear resistance. They do not react with the components of the raw alcohol/brag, and therefore such a nozzle with proper care will serve you for many years.

Ceramic Pall Ring, 50x50x5mm, VFF reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.