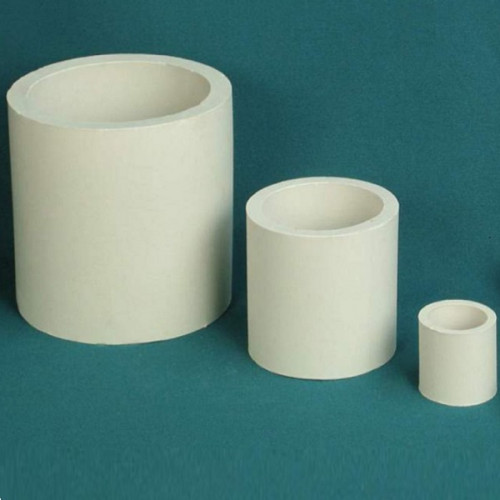

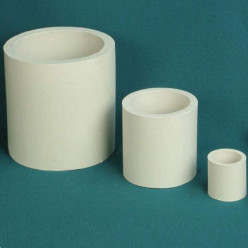

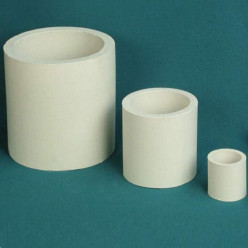

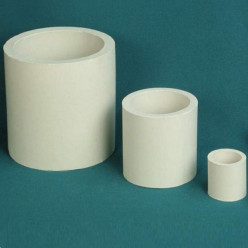

Сeramic Raschig Ring А1, 120х120х12 mm, GOST 473

Brand:

BTS EngineeringCharacteristics

Producer:

BTS Engineering

Pour density, kg/m3:

562

Specific surface area, m2/m3:

43

Dimensions, mm:

120x120x12

Nozzle type:

Raschig Ring

Thickness mm:

12

Void factor, %:

77

See all

Categories

Favorite

Compare

Products from the same category

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Сeramic Raschig Ring А1, 120х120х12 mm, GOST 473

Producer | BTS Engineering |

Pour density, kg/m3 | 562 |

Specific surface area, m2/m3 | 43 |

Dimensions, mm | 120x120x12 |

Nozzle type | Raschig Ring |

Thickness mm | 12 |

Void factor, % | 77 |

Diameter, mm | 120 |

Material | Ceramics |

Country of Origin | Ukraine |

Application | дистиляции, дегидратации, абсорбера, десорбера, очистки газов, декарбонизатора, насадочных колонн, сатурации воды, ректификации |

Analogue for | AMACS, Koch-Glitsch, Christy Catalytics, НКС DOLSIN, Ultimo Engineers, Munters, MACH Engineering LLC, Pall Ring Company, MTE |

Description Сeramic Raschig Ring А1, 120х120х12 mm, GOST 473

Acid-resistant ceramic nozzles (Rashig Rings) are designed to fill the nozzles of columns, absorbers, extractors, converters in the chemical, medical and refining industries.

The purpose of using nozzles - mixing, redistribution of the active mass, increasing the contact of the surfaces of the liquid and gas phases, improving heat transfer processes in the equipment.

According to the sintering of the ceramic shard, the nozzles are divided into two classes:

A - tightly sintered

В - porous.

The composition of the mass of the nozzles of class A are divided into two brands:

A1 of porcelain and cardierite mass;

A2 of semi-porcelain mass.

Cylindrical nozzles (Rashiga rings) are available in the form of thin-walled rings with a diameter of 15 to 150 mm, with the outer diameter of the ring equal to the height of the nozzle.

Physico-chemical and mechanical parameters of cylindrical nozzles:

Water absorption, not more than 0.5% test method according to GOST 473.3

Acid resistance, not less than 98.7% test method according to GOST 473.1

Thermal stability, number of heat changes, not less than 8 test method according to GOST 473.5.

Сeramic Raschig Ring А1, 120х120х12 mm, GOST 473 reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.