Inert ceramic balls DURANIT® D-99, 3, VFF

Brand:

VFFCharacteristics

Producer:

VFF

Pour density, kg/m3:

1900-2000

Specific surface area, m2/m3:

45

Nozzle type:

Inert balls

Void factor, %:

40-45

Max.temperature, C:

1 800

AL2O3 content:

~ 99%

See all

Categories

Favorite

Compare

Products from the same category

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Inert ceramic balls DURANIT® D-99, 3, VFF

Producer | VFF |

Pour density, kg/m3 | 1900-2000 |

Specific surface area, m2/m3 | 45 |

Nozzle type | Inert balls |

Void factor, % | 40-45 |

Max.temperature, C | 1 800 |

AL2O3 content | ~ 99% |

Diameter, mm | 72-80 |

Material | Ceramics |

Country of Origin | Germany |

Analogue for | AMACS, Koch-Glitsch, Christy Catalytics, НКС DOLSIN, Ultimo Engineers, Munters, MACH Engineering LLC, Pall Ring Company, MTE |

Description Inert ceramic balls DURANIT® D-99, 3, VFF

DURANIT®- ideal compressive strength for maximum operational reliability. Processes in which catalyst calipers are used in accordance with international specifications cover a whole range of thermal and catalytic transformations of the substance: Duranit® inert balls and other forms can also be used for other purposes, for example, in high-temperature filtration to separate solid and liquid particles from hot exhaust gases.

Applications: alkylation, catalytic reforming, dehydrogenation, hydrotreating, desulfurization, isomerization, catalytic cracking, power forming, catalytic conversion, thermal cracking, catalytic oxidation and other processes.

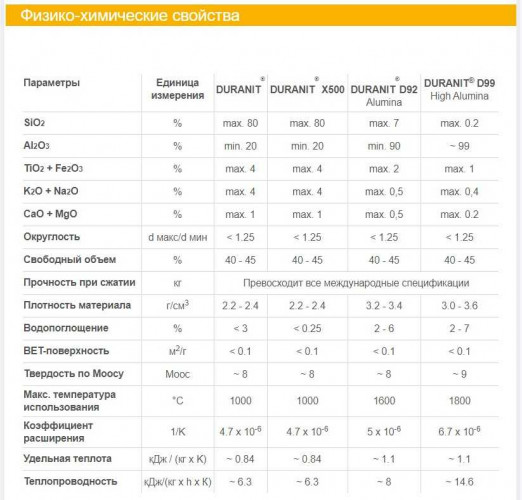

Chemical composition:

SiO2 < 0,2%

Al2O3+TiO2 > 99%

Fe2O3 ~ 0,1%

CaO + MgO ≤ 0,2%

K2O + Na2O ≤ 0,4%

Characteristics:

Specific surface area according to the BET method <0.1 m2 / g

Mohs hardness ~ 9

Specific heat: ~1.1 kJ•(kg * K)

Thermal conductivity: ~15 kJ / (M * h * K)

Thermal expansion: ~7•10-6 1/ K

Maximum temperature: ~1800°C

Water absorption (DIN EN 993-1): 2-6%

Inert ceramic balls DURANIT® D-99, 3, VFF reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.