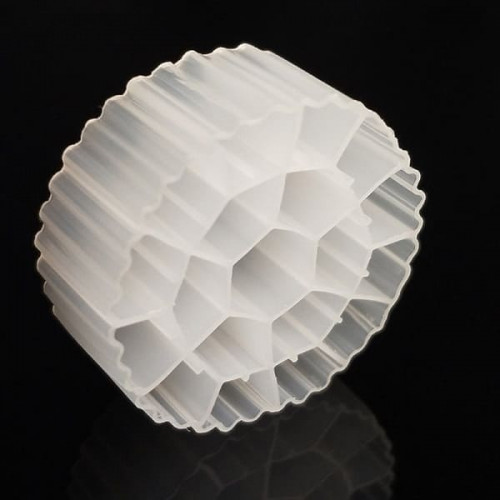

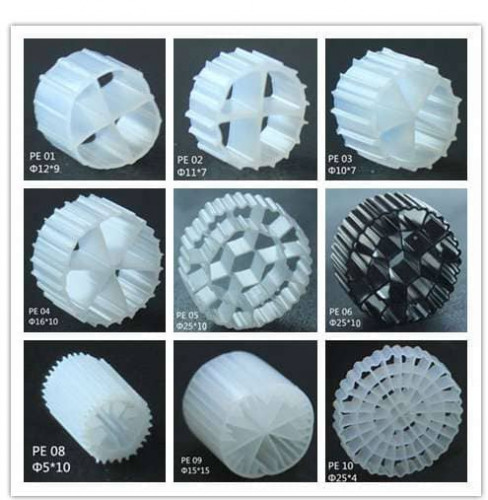

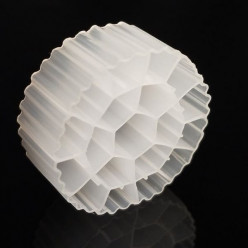

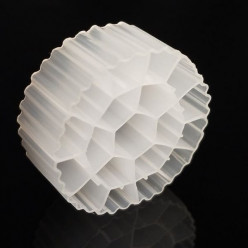

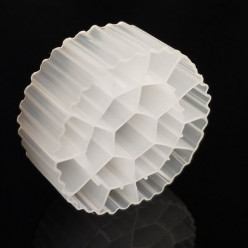

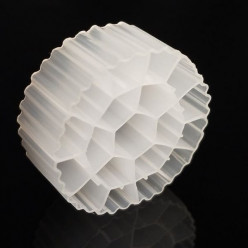

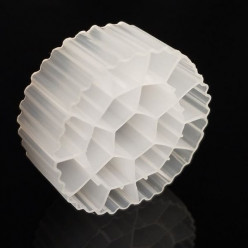

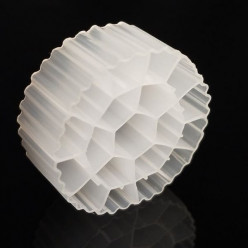

Reactor with a moving layer of biofilm MBBR01-12x9 mm

Brand:

BTS EngineeringCharacteristics

Producer:

BTS Engineering

Pour density, kg/m3:

120

Oxidation efficiency of BOD5, gBOD5/m3.d:

2000-10000

Specific surface area, m2/m3:

˃800

Specific Gravity, g/cm3:

0,96-0,98

Cod oxidation efficiency, Gcod/m3.d:

2000-15000

Operating temperature:

5°C-60°C

See all

Categories

Favorite

Compare

Products from the same category

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Reactor with a moving layer of biofilm MBBR01-12x9 mm

Producer | BTS Engineering |

Pour density, kg/m3 | 120 |

Oxidation efficiency of BOD5, gBOD5/m3.d | 2000-10000 |

Specific surface area, m2/m3 | ˃800 |

Specific Gravity, g/cm3 | 0,96-0,98 |

Cod oxidation efficiency, Gcod/m3.d | 2000-15000 |

Operating temperature | 5°C-60°C |

Dimensions, mm | 12x9 |

Service life, years | ˃15 |

Nozzle type | фильтрующий материал (MBR Filter Media) |

Void factor, % | ˃85 |

Number of holes | 4 |

Dosage factor, % | 15-67 |

Height, mm | 9 |

Diameter, mm | 12 |

Membrane formation time, days | 3-15 |

Material | PE |

Nitrification efficiency, gNH4-N/m3.d | 400-1200 |

Country of Origin | China |

Analogue for | AMACS, Koch-Glitsch, Christy Catalytics, НКС DOLSIN, Ultimo Engineers, Munters, MACH Engineering LLC, Pall Ring Company, MTE |

Description Reactor with a moving layer of biofilm MBBR01-12x9 mm

Biofilm carrier MBBR is a new carrier of biological suspension, which modified polymetric material with the addition of a bio-enzyme, adapted for all types of microganism, for rapid growth and reproduction, in order to dissolve organic matter in water.

MBBR biofilm transfer process features high specific surface area, easy biofilm propagation, high denitrification, good hydrophilicity, high biological activity, and so on, It is widely used in MBBR biofilter for wastewater treatment, aquaculture farms, Koi filter media, etc.

Peculiarities of the product:

1. Self-cleaning through turbulence

2. Due to the turbulent motion of the biofilter in suspension, the filter material is self-cleaning and does not require maintenance. This allows the filter to achieve optimum efficiency without disrupting periodic maintenance, avoiding unnecessary loss of bacteria inside the filter. This ensures a stable low ammonia and nitrite content in the water.

3. The high surface area of these products results in a small physical area required for the biofiltration plant.

Thanks to the intensive mixing of a medium like Kaldnes, aerated medium is self-cleaning and maintenance-free. This allows the filter to achieve optimum efficiency. Periodic maintenance is not required, which prevents unnecessary loss of bacteria and subsequent surges of ammonia and nitrite in the system.

Required Carrier Volume - With good turbulence and aeration, a 50 liter filter is needed to deliver from 0.25 kg to 0.75 kg 40% protein per day.

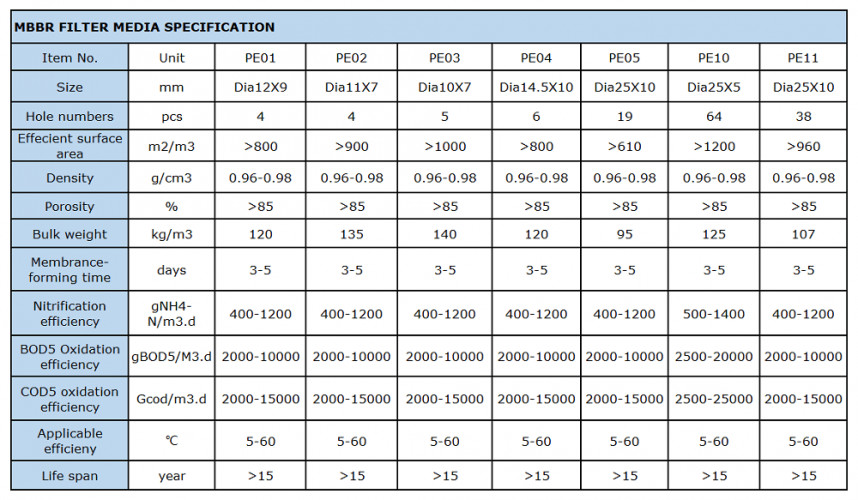

Size, mm - 12х9

the number of holes, pcs -4

Effective surface area, m2/m3 - 800

Density, g/cm3 - 0.96-0.98

Porosity, % - > 85

Bulk weight, kg / m3 - 120

Formation time of membrane, days -3-5

Nitrification efficiency, gNH4 N/m3.d - 400-1200

Oxidation effiicency BOD5, gBOD5/M3.d - 2000-10000

Oxidation efficiency COD5, Gcod/m3.d- 2000-15000

Temperature, °С-5-60

Durability, years - >15

Reactor with a moving layer of biofilm MBBR01-12x9 mm reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.