Pall Rings, PP, 25 mm, 69 kg / m3, Pall Ring Company

Brand:

Pall Ring CompanyCharacteristics

Producer:

Pall Ring Company

Pour density, kg/m3:

69

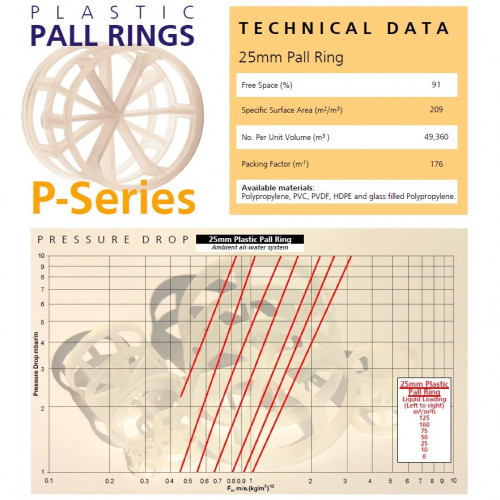

Specific surface area, m2/m3:

209

Nozzle type:

Pall Ring

Quantity m.cubic:

49 360

Void factor, %:

91

Diameter, mm:

25

See all

Categories

Favorite

Compare

Products from the same category

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Pall Rings, PP, 25 mm, 69 kg / m3, Pall Ring Company

Producer | Pall Ring Company |

Pour density, kg/m3 | 69 |

Specific surface area, m2/m3 | 209 |

Nozzle type | Pall Ring |

Quantity m.cubic | 49 360 |

Void factor, % | 91 |

Diameter, mm | 25 |

Material | PP |

Country of Origin | United Kingdom |

Analogue for | AMACS, Koch-Glitsch, Christy Catalytics, НКС DOLSIN, Ultimo Engineers, Munters, MACH Engineering LLC, Pall Ring Company, MTE |

Description Pall Rings, PP, 25 mm, 69 kg / m3, Pall Ring Company

Although Raschig Rings and Pall Rings have similar cylindrical dimensions, the Pall Ring has the advantage of having two rows of punched holes with inwardly curved tabs, which greatly improves the performance of the tip in terms of throughput, efficiency and drop. pressure. We can offer this type of packing in various plastic variations: PP, PVDF, HDPE, glass-filled polypropylene and PVC. Power and pressure drop • Most suitable for low pressure drops, high performance; • Wide range of sizes allows to work with optimal efficiency and provides good throughput; • Consistent ratio of free and blocked passages, independent of direction; • Large specific surface area: the volume factor increases the rate of surface renewal of the liquid film to improve mass transfer. Delay and two-phase contact • Promotes highly efficient two-phase contact and distribution; • Relatively high fluid reserve contributes to high absorption efficiency, especially in cases where the reaction rate is slow; • Uninterrupted and consistent passages for gas and liquid flow. Versatility • Open, stitched design provides highly efficient use of ring surface area; • Resistant to liquid and vapor distribution. mechanical strength • The internal transverse structure of the diametrical spars makes the packing mechanically strong and is suitable for use in deep columns.

Pall Rings, PP, 25 mm, 69 kg / m3, Pall Ring Company reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.