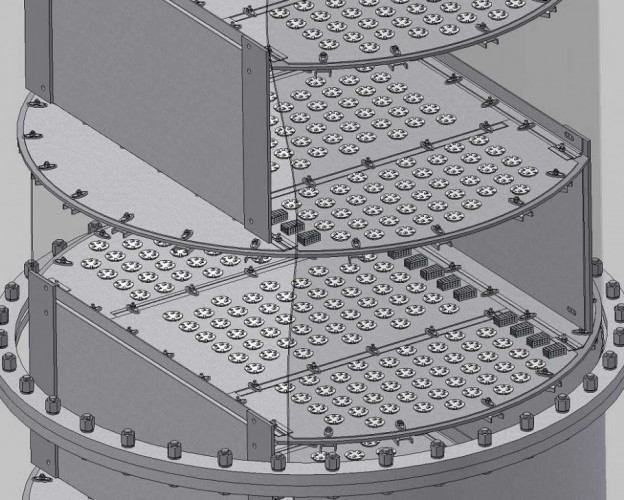

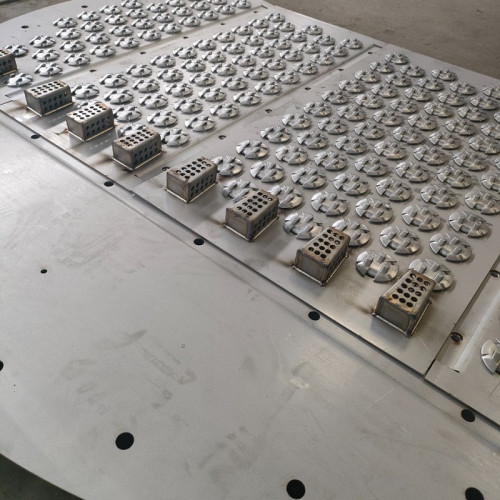

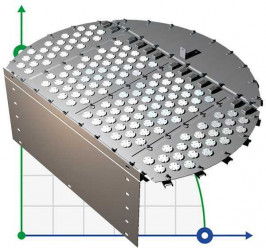

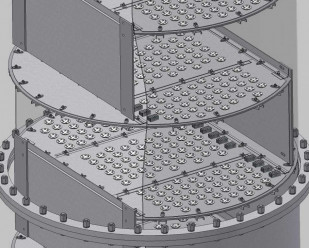

LPG purification column plate ATK 26-02-1-89, 1000 mm, SS 321 modified, h-500 mm

Brand:

BTS EngineeringCharacteristics

Producer:

BTS Engineering

Button width,mm:

3

Valve thickness, mm:

2

Number of valves, pcs:

48

Relative free passage area, %:

7,76

Area, m2:

0.78

Diameter, mm:

1 000

See all

Favorite

Compare

Products from the same category

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures LPG purification column plate ATK 26-02-1-89, 1000 mm, SS 321 modified, h-500 mm

Producer | BTS Engineering |

Button width,mm | 3 |

Valve thickness, mm | 2 |

Number of valves, pcs | 48 |

Relative free passage area, % | 7,76 |

Area, m2 | 0.78 |

Diameter, mm | 1 000 |

Distance between button mm | 500 |

Material | AISI 321 |

Valve type | ADV EDV |

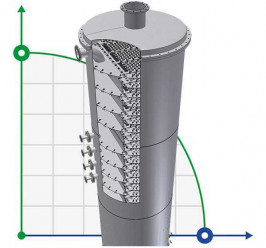

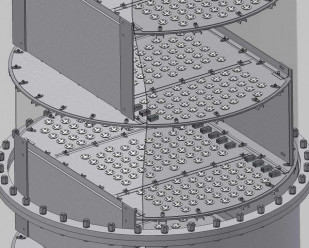

Description LPG purification column plate ATK 26-02-1-89, 1000 mm, SS 321 modified, h-500 mm

The resistance of the plates depends on the resistance coefficient of the dry plate, i.e. the plate without a liquid layer, and the resistance coefficient of the plate with a liquid layer. Also, for large columns, the column mode coefficient is included in the calculation of the resistance, which implies the heating temperature of the cube part and the amount of phlegm that is used to irrigate the plates.

The operating mode is the interaction of steam and liquid, the operating mode includes such parameters as: steam volume (heating intensity of the cubic part), amount of phlegm (volume of liquid used for irrigation of the plates). The mode also includes the amount of liquid on the plates, it is regulated by the height of the partition on the distillation plate, if the liquid overflows the partition, then choking occurs, which leads to a minimum quality of interaction between steam and liquid, if the height of the liquid layer is small, then the vapours rising from the bottom of the column are practically not enriched with phlegm (nkk).

The valve plates are widely used in the petrochemical and distillation industries, with column diameters ranging from 0.5 to 10 m, with plate spacing from 170 to 1100 mm, with designs ranging from single-stream to six-stream and with a number of plates ranging from a few to more than 200. The EDV® plate is also used in vacuum and high-pressure systems. The main advantages of these plates are their ability to provide efficient mass transfer over a wide range of working loads, simple design, low metal consumption and low cost.

LPG purification column plate ATK 26-02-1-89, 1000 mm, SS 321 modified, h-500 mm reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.