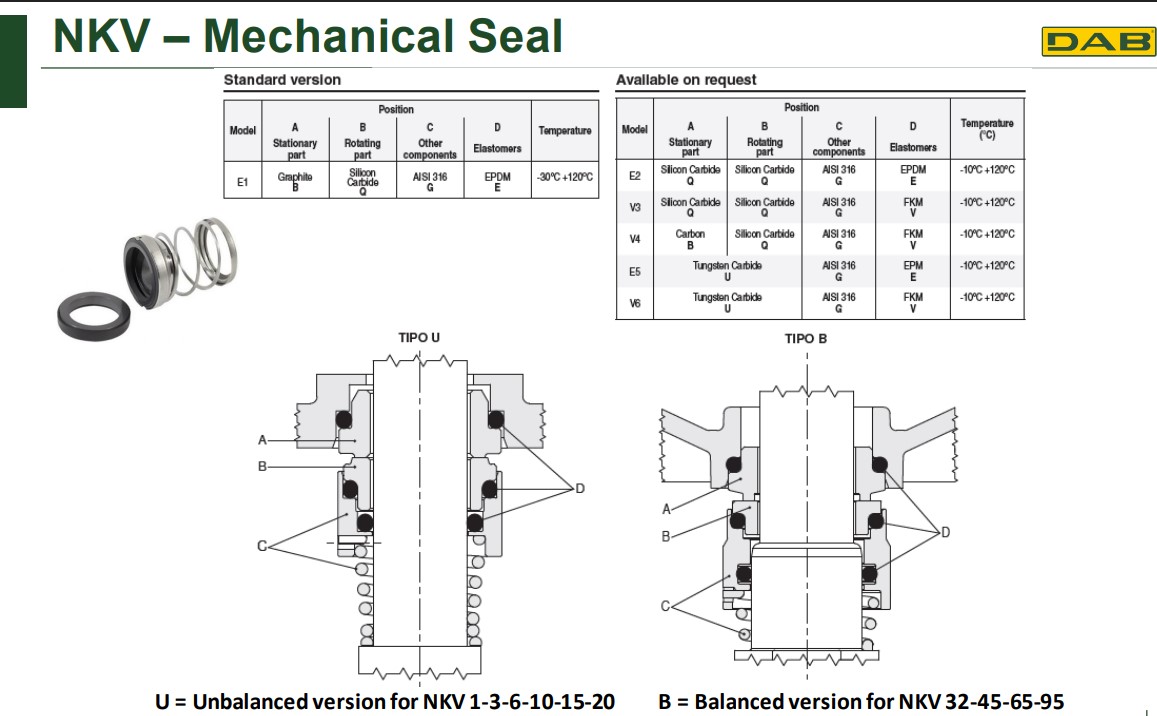

Types of mechanical seals for DAB NKV multistage pumps:

- Type U — unbalanced design for NKV 1-3-6-10-15-20

- Type B — balanced design for NKV 32-45-65-95

- E1 – BQGE – Carbon / Silicon carbide / AISI 316 / EPDM

Other options:

- E2 – QQGE – Silicon carbide / Silicon carbide / AISI 316 / EPDM

- V3 – QQGV – Silicon carbide / Silicon carbide / AISI 316 / FKM

- V4 – BQGV – Carbon / Silicon carbide / AISI 316 / FKM

- E5 – UUGE – Tungsten carbide / Tungsten carbide / AISI 316 / EPDM

For models with motor power above 4 kW, there is no need to dismantle the motor — the mechanical seal is installed in a cartridge-type design.

We performed the replacement of SP00001769 (QBE mechanical seal for NKV 95 REV. No. 1).

As a general guideline for selecting mechanical seal materials, we provide the information below (type of liquid, concentration, temperature, recommended seal type). It is important to consider specific operating conditions, in particular the specific gravity and/or viscosity of the liquid, as well as its pressure. You can contact us for additional information.

- Acetic acid 10–40% +0/+70 °C — E1

- Citric acid 5% +5/+70 °C — E1

- Hydrochloric acid 2% +5/+25 °C — V3

- Formic acid 5% +5/+25 °C — E1

- Phosphoric acid 10% +5/+30 °C — E1

- Nitric acid 40% +5/+30 °C — V3

- Sulfuric acid 2% +5/+25 °C — V4

- Tannic acid 20% +5/+50 °C — E1

- Tartaric acid 50% +5/+25 °C — V3

- Deionized water, demineralized water 100% +5/+110 °C — E1

- Sodium bicarbonate 6% +5/+60 °C — E1

- Chloroform 100% −10/+30 °C — V4

- Oil-in-water emulsion 100% +15/+90 °C — V4

- Phosphates–polyphosphates 10% +5/+90 °C — V3

- Ethylene glycol 10–30% −15/+120 °C — E1

- Propylene glycol 30% −10/+100 °C — V3

- Sodium hypochlorite 1% +5/+25 °C — V3

- Sodium nitrate 10% +5/+60 °C — V3

- Heat transfer oil 100% +90/+120 °C — V4

- Mineral oil 100% +90/+120 °C — V4

- Vegetable oil 100% +70/+100 °C — E1

- Perchloroethylene 100% −10/+30 °C — V4

- Sodium hydroxide 25% +5/+70 °C — E2

- Aluminum sulfate 10–25% +5/+50 °C — E2

- Ammonium sulfate 10% −10/+60 °C — E2

- Iron sulfate 10% +5/+30 °C — E1

- Trichloroethylene 100% −10/+40 °C — V4

You can contact BTS Engineering for additional information.

0 comments