You need to purchase a mechanical seal for a hot oil pump with a temperature of 90 2 217 3 300 3 350°C etc?

Receiving such requests, our engineers are constantly faced with customers' lack of understanding of the principles of operation of centrifugal pumps hot oil circulation pumps, as well as with the principle of operation of mechanical seals in them.

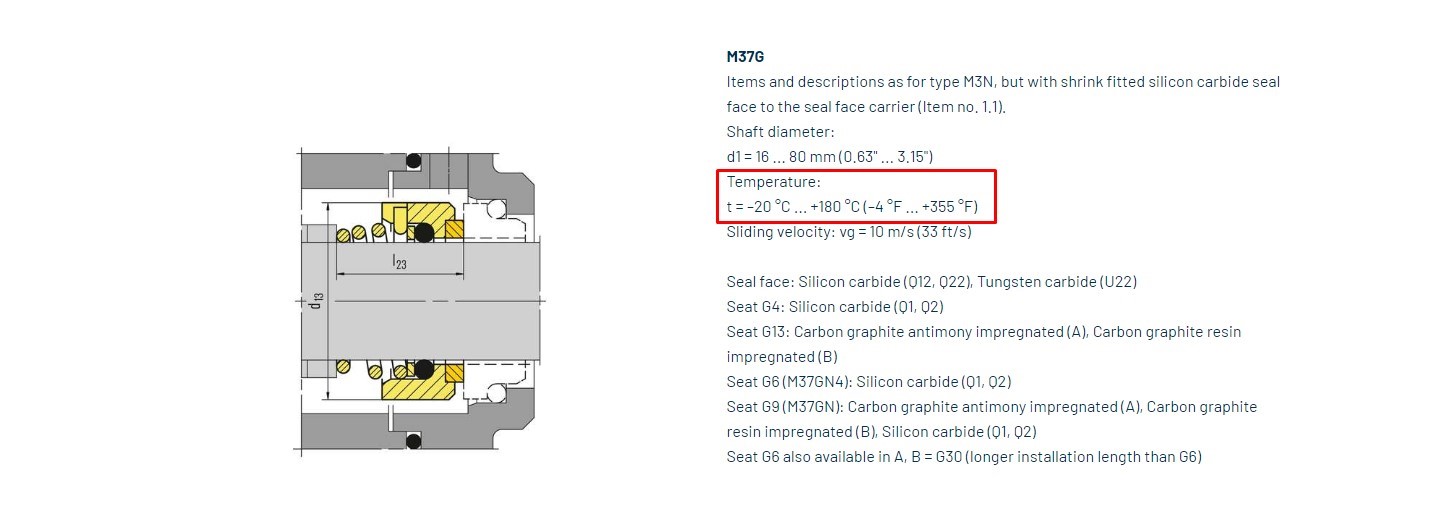

Most well-known manufacturers install in such pumps mechanical seals are single, unbalanced, using silicon carbide and/or graphite materials and FKM Viton rubber elements. Looking through the range of world-famous manufacturers of mechanical seals (EagleBurgmann, Flowserve, John Crane, etc.), we are faced with a strange situation – such mechanical seals can withstand temperatures in the range of -20 2 200°C, and not 280° etc.

What's the matter? Don't pump equipment manufacturers (such as KSB, Sihi, Allweiler, Dean, Kontro, Dickow, etc.) understand mechanical seals? Or do they design any special seals made of materials that are unusual and unusual in their properties?

The answer lies in the plane of elementary consideration of the structure of centrifugal thermal oil pumps.

- The centrifugal pump for hot coolant is an air-cooled pump with a cast radiator for removing the thermal load of the shaft chamber and installed mechanical seals.

- The heat of the pumped product is effectively reduced by special cooling fins and the maximum distance of the mechanical seal from the hot flow part due to the extended shaft.

- In addition, the ribbed bearing frame contributes well to heat dissipation, which ensures reliable operation of the mechanical seal.

- Also, these pumps are additionally equipped with a safe stuffing box seal and a throttling zone before mechanical sealing.

That is, we see that all models have one or another passive cooling system the pumping unit. At the same time, bearings and mechanical seals in such pumps are lubricated with pumping products, which requires filtration of the product at the inlet, to prevent aggressive impurities from entering the internal components.

The change in liquid temperature can be clearly seen in the following graph:

Therefore, taking into account the above information, BTS Engineering mechanical seals will fully provide your equipment with all the necessary protection and smooth operation of thermal oil pumps.

1 comment

site needs a great deal more attention. I'll probably be back again to

read through more, thanks for the information! https://ternopil.pp.ua/