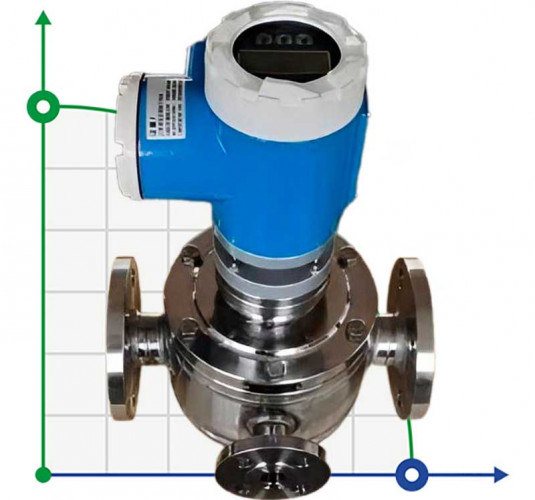

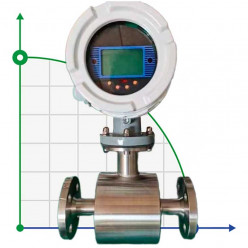

DN65 Stainless gear flowmeter for molasses, bitumen LC-TUB50K65.2/BELZ DN65, 2-12 m3/h, 2-2000 mPa.s, 4-20mA with heating jacket

Brand:

BTS EngineeringCharacteristics

Producer:

BTS Engineering

Housing material:

AISI 304 stainless steel

Control signal, mA:

4-20

Accuracy class (measurement error), %:

±0.5

Operating temperature:

-20°C +100°C

Nom.pressure, Mpa:

1,6

Voltage, V:

24

See all

Documentation

Favorite

Compare

Products from the same category

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures DN65 Stainless gear flowmeter for molasses, bitumen LC-TUB50K65.2/BELZ DN65, 2-12 m3/h, 2-2000 mPa.s, 4-20mA with heating jacket

Producer | BTS Engineering |

Housing material | AISI 304 stainless steel |

Control signal, mA | 4-20 |

Accuracy class (measurement error), % | ±0.5 |

Operating temperature | -20°C +100°C |

Nom.pressure, Mpa | 1,6 |

Voltage, V | 24 |

Connection type | flanged |

Connection diameter, DN | 65 |

Viscosity | 2-2000 mPa.s |

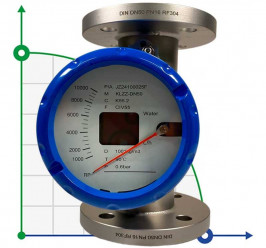

Type of flow meter | gear |

Country of Origin | China |

Description DN65 Stainless gear flowmeter for molasses, bitumen LC-TUB50K65.2/BELZ DN65, 2-12 m3/h, 2-2000 mPa.s, 4-20mA with heating jacket

The oval gear flowmeter is composed of a metering unit and a pair of elliptical gears installed in the metering unit, and the upper and lower covers form a crescent-shaped sealed cavity (due to the rotation of the gear, it is not sealed) as the calculation unit of displacement.

When the measured fluid enters the flowmeter through the pipeline, the pressure difference generated at the inlet and outlet pushes the gear pair to rotate continuously, and the fluid measured by the crescent-shaped cavity is continuously transported to the outlet. The product of four times the secondary volume is the total measured fluid flow.

The elliptical gear generates a torque that causes it to rotate under the influence of the pressure difference △p of the measured medium.

Rotor 1 and rotor 2 are alternately driven by one to rotate the other. Each rotor has two magnets as signal generation elements. In the centre of the two axes at the bottom of the cavity is a magnetic signal detection element. Each time the magnet returns to the detection element, the sensor counts a pulse. Each pulse corresponds to a certain amount of media discharge, so the volumetric flow rate of the media removed by each pulse can be obtained.

Documentation DN65 Stainless gear flowmeter for molasses, bitumen LC-TUB50K65.2/BELZ DN65, 2-12 m3/h, 2-2000 mPa.s, 4-20mA with heating jacket

Download instructions, catalog for DN65 Stainless gear flowmeter for molasses, bitumen LC-TUB50K65.2/BELZ DN65, 2-12 m3/h, 2-2000 mPa.s, 4-20mA with heating jacket

DN65 Stainless gear flowmeter for molasses, bitumen LC-TUB50K65.2/BELZ DN65, 2-12 m3/h, 2-2000 mPa.s, 4-20mA with heating jacket reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.