Stainless steel thermal gas mass flow meter DN400/PN16 (compressed air), 45-36500 Nm3/h, 4-20mA+RS485, plug-in

Brand:

BTS EngineeringCharacteristics

Producer:

BTS Engineering

Housing material:

AISI 304 stainless steel

Display:

English-display, cumulative and instantaneous flow display

Control signal, mA:

4-20mA+RS485

Accuracy class (measurement error), %:

2,5

Operating temperature:

85°C

Protection:

IP65

See all

Documentation

Favorite

Compare

Products from the same category

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Stainless steel thermal gas mass flow meter DN400/PN16 (compressed air), 45-36500 Nm3/h, 4-20mA+RS485, plug-in

Producer | BTS Engineering |

Housing material | AISI 304 stainless steel |

Display | English-display, cumulative and instantaneous flow display |

Control signal, mA | 4-20mA+RS485 |

Accuracy class (measurement error), % | 2,5 |

Operating temperature | 85°C |

Protection | IP65 |

Flow range | 45...36500 Nm3/h |

Explosion protection | No |

Nom.pressure, Mpa | 1,6 |

Voltage, V | 24 |

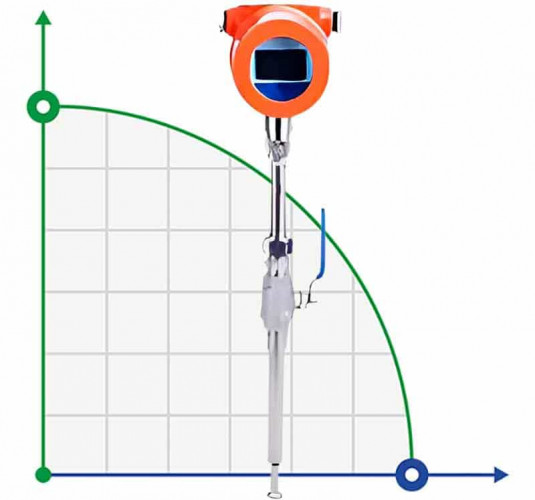

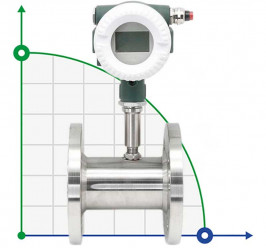

Connection type | Plug-in |

Connection diameter, DN | 400 |

Type of flow meter | thermal gas mass flow meter |

Country of Origin | China |

Description Stainless steel thermal gas mass flow meter DN400/PN16 (compressed air), 45-36500 Nm3/h, 4-20mA+RS485, plug-in

Thermal mass gas flow meter is developed on the basis of thermal dispersion and uses the constant temperature difference method to measure gas flow. It has the advantages of small size, easy installation, high reliability and high measurement accuracy, etc.

The flow meter contains two platinum resistance temperature sensors.

The thermal principle works by monitoring the cooling effect of the gas flow as it passes over the heated sensor. The gas flowing through the sensing section passes over two sensors, one of which is used traditionally as a temperature sensor and the other as a heater. The temperature sensor monitors the actual process values, while the heater maintains a constant temperature difference by varying the power consumed by the sensor. The greater the gas velocity, the greater the cooling effect and the power required to maintain the temperature difference. The measured heater power is therefore a measure of the mass flow rate of the gas.

Documentation Stainless steel thermal gas mass flow meter DN400/PN16 (compressed air), 45-36500 Nm3/h, 4-20mA+RS485, plug-in

Download instructions, catalog for Stainless steel thermal gas mass flow meter DN400/PN16 (compressed air), 45-36500 Nm3/h, 4-20mA+RS485, plug-in

Stainless steel thermal gas mass flow meter DN400/PN16 (compressed air), 45-36500 Nm3/h, 4-20mA+RS485, plug-in reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.