Ethylene glycol pumps

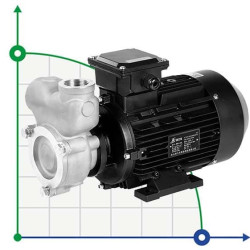

Ethylene glycol pumps are equipment for transporting liquids containing ethylene glycol, which is effectively used in some heating systems. The mixture retains its basic properties, has a low freezing point, as well as a high boiling point, which has a positive effect on the properties of a system with such a filling. Ethylene glycol pumps are reliable and high-quality, have an additional explosion-proof motor, as well as membranes for protection. Such design changes are due to the properties of the liquid, which requires excessive power from the pump for efficient pumping.

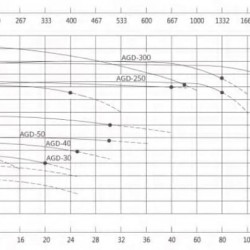

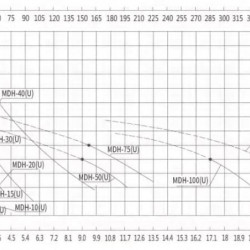

The ethylene glycol pump must create sufficient pressure in the system, since the solution has a higher viscosity and is more difficult to transport. Due to its properties, it also loses temperature faster, so you need to create a sufficient level of flow rate with maximum maintenance of the feed rate. It is important to remember that ethylene glycol solution is toxic to humans. Accordingly, the pump for transportation must be reliable and sealed to eliminate the possibility of accidental leaks of liquid.

Which pumps are suitable for transporting ethylene glycol?

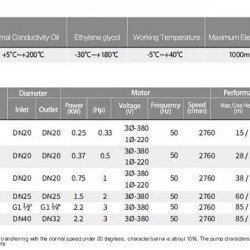

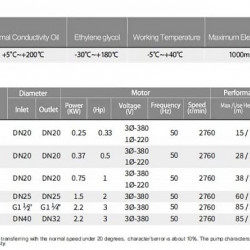

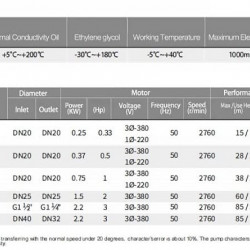

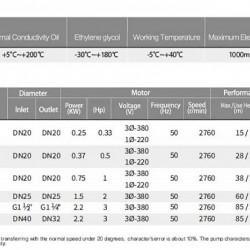

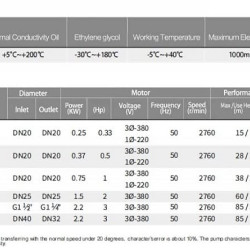

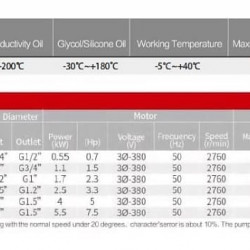

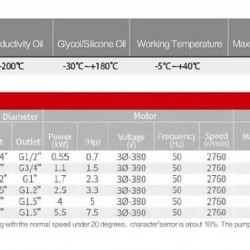

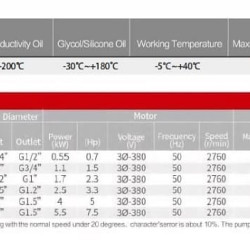

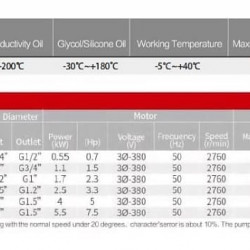

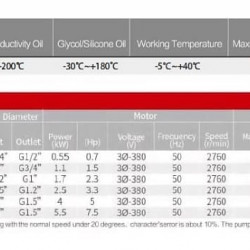

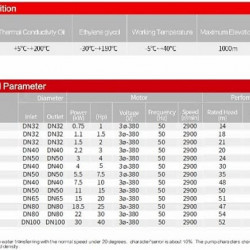

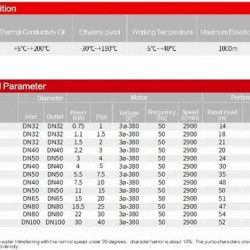

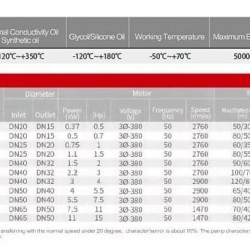

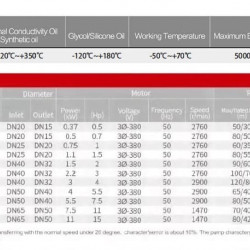

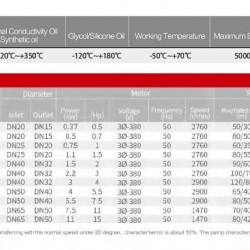

Ethylene glycol solution does not cause corrosion, so many pumps made of different materials are suitable for its transportation. Before selecting a pump, it is necessary to study its technical characteristics and pay attention to the maximum temperature that the pump can withstand.

For low temperatures, as well as low network pressure, centrifugal pumps with mechanical shaft seals are used, because without such a seal, a solution that is toxic to humans can leak.

For situations where the solution will have a higher temperature and pressure, it is better to use pumps with a magnetic drive. This is due to changes in temperature and loss of sealing properties of mechanical seals. These pumps use special rings to contain the solution and protect the entire system from leakage.

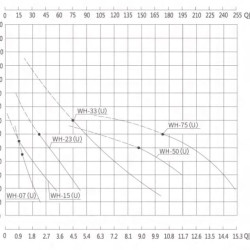

You should choose the right device taking into account all the features of the project: the location of the pump, the duration and frequency of its operation, the capacity and performance of the pump. All these parameters are difficult to take into account, but the specialists of our online store will be happy to inform you about all the features of each model of ethylene glycol pumps. Before you buy a device at the best price, you should contact our managers to clarify the necessary nuances.

Advantages of using ethylene glycol pumps

The use of pumps that are designed to transport a certain type of solution for cooling or heating a certain environment has many advantages. In particular it is worth highlighting the following:

- Rational use of resources,properties and capacities of both the solution and the pump;

- Optimization of processes by already configuring the equipment for a specific project;

- Reduce the cost of maintenance and subsequent repair of equipment.

At the same time, it should always be remembered that the use of high-quality products protects the entire network from problems. Therefore, a certified and proven ethylene glycol pump will help to transport the solution reliably and efficiently in the system.