Drum pump BTS-HD-A1+AL-HP-1000mm (air driving motor )

Brand:

BTS EngineeringCharacteristics

Output pipe diameter:

25 mm

Producer:

BTS Engineering

Power capacity, Wt:

370

Max. head, m:

9

Rate of turn, rpm:

9 500

Feed height, m:

9

Max.air pressure, bar:

7

See all

Documentation

Categories

Favorite

Compare

Products from the same category

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Drum pump BTS-HD-A1+AL-HP-1000mm (air driving motor )

Output pipe diameter | 25 mm |

Producer | BTS Engineering |

Power capacity, Wt | 370 |

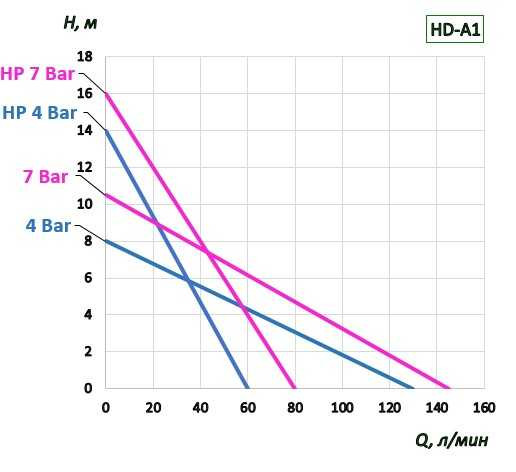

Max. head, m | 9 |

Rate of turn, rpm | 9 500 |

Feed height, m | 9 |

Max.air pressure, bar | 7 |

Max.viscosity, cPs | 700 |

Model | BTS НР |

Pump capacity, m3/h | 6 |

Flow rate, l/min | 100 |

Explosion protection | Yes |

Max.temperature, C | 100 |

Shaft material | AISI 304 stainless steel |

Length, mm | 1000 |

Material of flow channel | AL |

Height, mm | 1 000 |

Input pipe diameter | 41 mm |

Material | AL |

Country of Origin | China |

PumpType | drum |

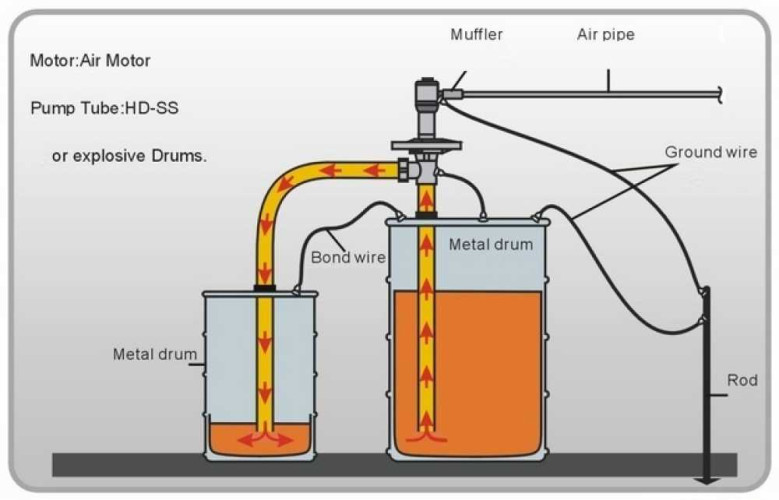

Drive Type | pneumatic |

Type of configuration | with engine |

Availability of spare parts | Yes |

Warranty, months | 12 |

Application | enzymes, pigments, food additives, food products, hydrofluoric acid, solvents, thickeners, of hydrochloric acid, fuel, acetic acid, chemistry, hardeners, chemically active liquids, alkalis, molasses, oil products, oils, CIP flushes, nitric acid, flavors, barrels, eurocube, acids |

Analogue for | Fluimac, JESSBERGER, Lutz, DAYTON, Debem |

Description Drum pump BTS-HD-A1+AL-HP-1000mm (air driving motor )

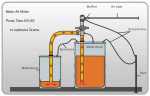

Drum pumps designated for transferring of various liquids from the cans, tanks and IBC containers. Drum pumps are made of different materials, e.g. stainless steel, Aluminum, PVC (poly vinyl chloride), Polypropylene and others.

The delivery of acids, alkalis and reagents in drums and IBC (intermediate bulk containers) became the common practice. Specified tare oftentimes is for turn back and it means that the tare must be tipped out quickly and carefully and the returned to sender. As the containers with down discharge forbidden in many countries because of the liquid restriction danger, the only possibility of pumping the liquid became the using of housing on lid. The best equipment for this work is drum pumps.

Drum pumps for chemically active liquids: sodium hydroxide, acetic acid, nitric acid, hydrofluoric acid and muriatic acid and others.

Drum pumps transfer food supplements, feed products, molasses, deckers, atomizers, liquid products – concentrates and ingredients. In industry: pumping and loading of reagents and liquids from plastic tare, IBCs and drums.

Drum pumps are widely used for transferring of petrochemicals, dissolvents, hardening agents and other components.

Documentation Drum pump BTS-HD-A1+AL-HP-1000mm (air driving motor )

Download instructions, catalog for Drum pump BTS-HD-A1+AL-HP-1000mm (air driving motor )

Drum pump BTS-HD-A1+AL-HP-1000mm (air driving motor ) reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.