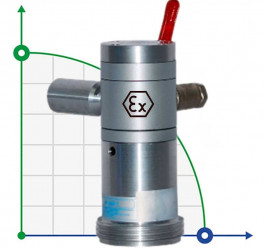

Pneumatic drive motor with explosion protection 375W to the barrel pump

Brand:

BTS EngineeringCharacteristics

Producer:

BTS Engineering

Power capacity, Wt:

375

Rate of turn, rpm:

9 500

Max.air pressure, bar:

7

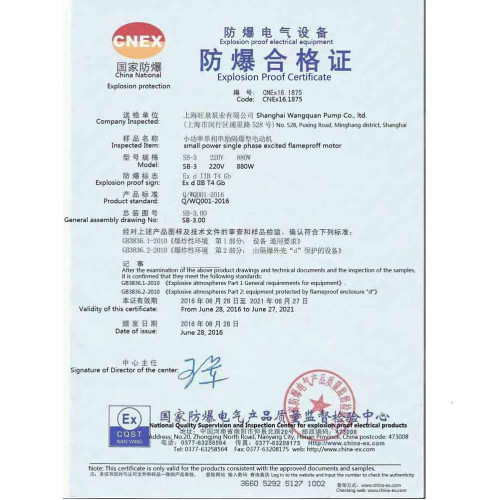

Explosion protection:

Yes

Country of Origin:

China

PumpType:

drum

See all

Documentation

Categories

Favorite

Compare

Products from the same category

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Pneumatic drive motor with explosion protection 375W to the barrel pump

Producer | BTS Engineering |

Power capacity, Wt | 375 |

Rate of turn, rpm | 9 500 |

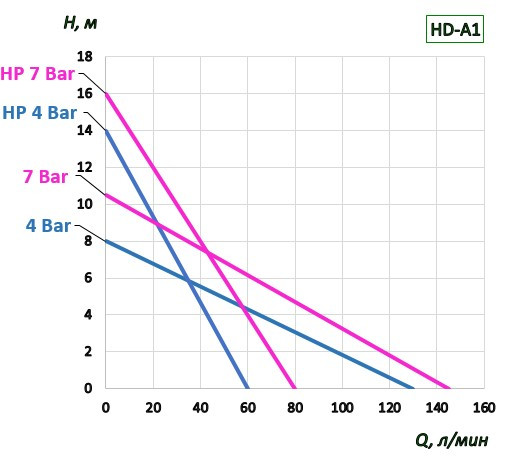

Max.air pressure, bar | 7 |

Explosion protection | Yes |

Country of Origin | China |

PumpType | drum |

Drive Type | pneumatic |

Warranty, months | 12 |

Application | chemically active liquids, thickeners, of hydrochloric acid, fuel, acetic acid, enzymes, chemistry, alkalis, hydrofluoric acid, solvents, food products, flavors, CIP flushes, nitric acid, barrels, food additives, eurocube, acids, oils, oil products, hardeners, molasses, pigments |

Analogue for | Debem, Fluimac, JESSBERGER, Lutz, DAYTON |

Weight, kg | 1,23 |

Description Pneumatic drive motor with explosion protection 375W to the barrel pump

Application: acid pumps, barrel pump, pigment pump, alkali pump, Eurocube pump, Eurocube pump, eurocube chemistry pump, enzyme pump, oil pump, fuel pump, solvent pump.

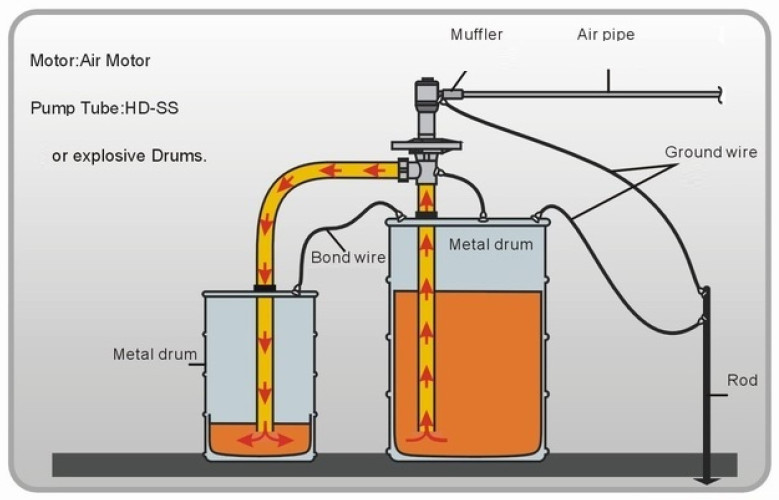

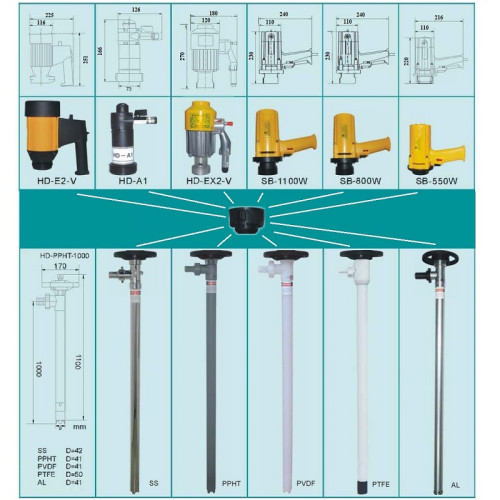

Barrel pumps are designed for pumping various types of liquids from cans, barrels and euro cubes. Barrel pumps are made of various materials, such as stainless steel, aluminum, PVC, polypropylene, etc.

The supply of acids, alkalis and reagents in barrels and IBC containers has become a common practice. The specified container is most often reversible, which means that it needs to be emptied quickly and carefully and returned to the sender. Since containers with a drain located at the bottom began to be banned in many countries due to the risk of spillage, the only way to pump out the liquid was to use a hole in the lid. Barrel pumps have become the most suitable equipment for this work.

Barrel pumps for chemically active liquids such as: sodium hydroxide, acetic acid, nitric acid, hydrofluoric acid, hydrochloric acid, nitric acid and others.

Barrel pumps also pump food additives, food products, molasses, thickeners, flavorings, enzymes, liquid products -concentrates and ingredients. In industry: pumping and unloading of reagents and liquids from plastic containers, euro cubes and barrels. Barrel pumps also pump petroleum products, solvents, hardeners and other components. Barrel pumps of this series are not inferior in quality and technical characteristics to pumps of such manufacturers as Debem, Fluimac, JESSBERGER, Lutz and other brands.

Documentation Pneumatic drive motor with explosion protection 375W to the barrel pump

Download instructions, catalog for Pneumatic drive motor with explosion protection 375W to the barrel pump

Pneumatic drive motor with explosion protection 375W to the barrel pump reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.