- Mechanical seals

- Mechanical seals by type

- R-101

- R-102

- R-102U

- R-103 / R-103A

- R-104 / R-104А

- R-108

- R-108U

- R-109 / R-8U

- R-109B / R-8B

- R-10T / R-10R

- R-110

- R-112

- R-113

- R-120 / R-120P

- R-120W

- R-124

- R-125

- R-128 / R-128P

- R-152 (T/R)

- R-1527

- R-156

- R-1577

- R-16

- R-202 / R-208

- R-21

- R-2100

- R-21UK

- R-260TS

- R-31K / R-31U

- R-4701

- R-4702

- R-502B

- R-560A

- R-560C

- R-58B / 59B

- R-58U / 59U

- R-58V

- R-6

- R-609/R-650

- R-680

- R-6A

- R-6B

- R-6BG

- R-6C

- R-6CF-16

- R-6CH-16

- R-6CK-16

- R-6SB / R-SB

- R-706A

- R-706B

- R-706C

- R-706D

- R-706E

- R-706F

- R-706H(CR)

- R-706K

- R-706L

- R-706SE

- R-706SO/706SSO

- R-706SP

- R-706SS

- R-802

- R-877/R-877-U

- R-960

- R-AL.FM

- R-AL.LKHd

- R-AL.LKHf

- R-AL.LKHs

- R-AL.SR

- R-APV-01

- R-B151

- R-BED

- R-BIA

- R-BT-AR

- R-BT-FN

- R-BT-FN.NU

- R-BT-RN

- R-BT-RN3 / R-BT-RN3.NU

- R-CARTEX(DN)

- R-CARTEX(SN)

- R-Convertor

- R-CSM

- R-CURC

- R-DJ

- R-E5K-U

- R-FL.58UR

- R-FL.NL

- R-FL.NU

- R-FL.OL

- R-FL.OU

- R-FL.XA

- R-FL.XE

- R-FL.С

- R-FR

- R-GEA

- R-GTZ

- R-H12N

- R-H75

- R-H7N

- R-HG202

- R-HG204 / R-HG204B

- R-HG212

- R-HJ92N / R-HJ97

- R-HLG

- R-HLG1

- R-HRN

- R-ISC2-PX

- R-J580

- R-JB103

- R-JB104

- R-JL

- R-LPS

- R-LW

- R-LWR

- R-M010D

- R-M07

- R-M2N

- R-M3.ALW

- R-M3N

- R-M481KL-D

- R-M74D

- R-M7N /M74

- R-MFL WT80

- R-MFL85N

- R-MFLC12

- R-MG1

- R-MG12

- R-MG13

- R-MG1S20

- R-MG1S6

- R-MG9

- R-MR35L-D

- R-MS

- R-SE1F-AP

- R-T1 / R-FBC

- R-T2 / R-FBD

- R-TSWE

- R-W01

- R-W011

- R-WB2

- R-WB3

- R-XB

- R-ZF

- Mechanical seal for pump

- Mechanical seals for ABS pumps

- Mechanical seals for Alfa Laval pumps

- Mechanical seals for Allweiler pumps

- Mechanical seals for Andritz pumps

- Mechanical seals for APV pumps

- Mechanical seals for Calpeda pumps

- Mechanical seals for DAB pumps

- Mechanical seals for Dia Pump pumps

- Mechanical seals for DP-Pumps pumps

- Mechanical seals for Ebara pumps

- Mechanical seals for EMU pumps

- Mechanical seals for Flygt pumps

- Mechanical seals for Foras pumps

- Mechanical seals for Fristam pumps

- Mechanical seals for GEA Tuchenhagen pumps

- Mechanical seals for Goetze pumps

- Mechanical seals for Grundfos pumps

- Mechanical seals for GÜCÜM pumps

- Mechanical seals for Hidrostal pumps

- Mechanical seals for Hilge pumps

- Mechanical seals for IMP Pumps

- Mechanical seals for Inbeat pumps

- Mechanical seals for INOX pumps

- Mechanical seals for Inoxpa pumps

- Mechanical seals for Jabsco pumps

- Mechanical seals for Johnson pumps

- Mechanical seals for KOLMEKS pumps

- Mechanical seals for KSB pumps

- Mechanical seals for LFP Leszno pumps

- Mechanical seals for Lowara pumps

- Mechanical seals for Mission Magnum pumps

- Mechanical seals for Mouvex pumps

- Mechanical seals for Nocchi pumps

- Mechanical seals for PACKO pumps

- Mechanical seals for Pasco pumps

- Mechanical seals for Pedrollo pumps

- Mechanical seals for PENTAX pumps

- Mechanical seals for POMPETRAVAINI pumps

- Mechanical seals for Pumpex pumps

- Mechanical seals for Robushi pumps

- Mechanical seals for SAER pumps

- Mechanical seals for Salmson pumps

- Mechanical seals for SPERONI pumps

- Mechanical seals for Sulzer pumps

- Mechanical seals for Tsurumi pumps

- Mechanical seals for Vulcan pumps

- Mechanical seals for Waukesha pumps

- Mechanical seals for Wilo pumps

- Mechanical seals for Wright Flow pumps

- Mechanical seals for ZENIT pumps

- Mechanical seals for K, KM, KML, KMS, BShM, KM35-32-130, KM50-32-125, KM32-22-120 pumps

- Mechanical seals by brand

- Seals for agitators, hoppers and conveyors withstand shaft runout

- Mechanical seals by type

- Pumps

- Barrel pumps

- Vacuum pumps

- Screw pumps

- Vortex pump

- Metering pumps and controllers

- Sewerage plants

- Console pumps

- Cam pumps

- Multistage pumps

- Monoblock stainless steel pumps

- Cast iron monobloc pumps

- Pumping stations of water supply and fire extinguishing

- Power take-off shaft pumps (PTO) for tractor

- Pumps of a double entrance type D

- Pumps for water supply wells

- Pumps and controllers for hydroponics

- Impeller pumps

- Pumps in-line

- Magnetic drive pumps

- Pumps with open and closed impeller DWO

- Stainless Steel Dry Rotor Pumps

- Self-priming pumps

- Peristaltic pumps

- Rotary vane pumps

- Pneumatic diaphragm pumps

- Pneumatic diaphragm submersible pumps for wells

- Submersible fecal drainage pumps

- Propeller pumps

- Control panels and automatics for pumps, pumping stations

- Chemical centrifugal pumps

- Centrifugal industrial pumps

- Circulation pump

- Gear pumps

- Electric diaphragm and plunger pumps

- Application of pumps by industry and liquid

- Stainless steel pumps for distillery dreg, mash, wort

- Pumps for wine

- Pumps for water supply

- Pumps for CAS

- Pumps for sewage pumping station

- Pumps for lagoons and manure pumping

- Milk pumps

- Hot water pumps

- Irrigation pumps

- Vegetable oil pumps

- Pumps for extreme temperatures from -196°C to +400°C

- Ethylene glycol pumps

- Pumps inline heating water supply

- Alternative energetics, generators

- Taps, gate valves, valves

- Separators and decanter centrifuges

- Bactofuga MAXCLEAN BACTERIA

- Decanters HAUS

- Whey separator MAXCLEAN

- Separator milk cleaner MAXCREAM

- F Series Beverage Industry

- Olive Oil Separators Series V

- Separators Series D dairy industry

- Separators DBA series

- Separators Series I Industrial Application

- MILKOTUNE series automatic milk processing installation

- Internal structures of columns and apparatuses

- Adsorbents, Desiccants, Catalysts

- 3A, 4A, 5A, 13x Molecular Sieve

- Packing For Sewage Treatment Plants

- Bio Ball For Wastewater Treatment Systems, Cooling Towers

- Combined Packing For Biological Oxidation And Water Treatment

- Poriferous Ball-Shaped Suspending Packing

- Biofilm Moving Bed Reactor, MBBR

- Inclined Plate Thin-Layer Module For Solids Removal From Waste Water Or Process Vapour

- Elastic Fillers For Homogeneous Separation Of Biofilm

- Irregular Random Packing

- Heat-resistant, Mineral, Inert Balls

- Ceramic Irregular Random Packing

- Metal Irregular Random Packing

- Plastic Irregular Random Packing

- Plastic Igel Ball

- Plastic Cascade Mini-Ring

- Plastic Snowflake Ring

- Plastic VSP Mella Ring

- Plastic Beta Ring

- Plastic Pal Ring

- Plastic Tellettes Ring

- Plastic Ralu Ring

- Plastic Raschig Ring

- Plastic Teller Rosette Ring

- Plastic Heilex Ring

- Plastic Conjugated Ring

- Plastic Polyhedra Hollow Ball

- Plastic HD/Q Packing Pak

- Plastic Packing LanPack

- Plastic Packing Q-Pack

- Plastic Packing Tri-Pak

- Plastic Balls With Cross Section Cover Ball

- Plastic Flat Ring

- Plastic Hollow Floatation Ball

- Plastic Moving Bed Biofilm Reactor MBBR

- Plastic Intalox Saddles

- Plastic Packing NorPack

- Plastic Super Raschig Ring

- Plastic Hexa-shield Solid Ball

- Structured Regular Packing

- Plates for Rectification, Distillation Columns

- Diesel engines with PTO of 3000 revolutions for pumps, compressors, fans, technology

- Material handling equipment, scales

- Production automation: controllers, instruments, sensors, flow meters

- Compressors

- Blowers

- hydrants

- Screw press

- API binding plans

- AESSEAL

- AIDA

- AIZL

- ALLWEILER

- AlphaDynamic

- ALUNAK

- ANGA

- AQUA

- ATLAS

- BIGIESSE

- BTS Engineering

- BURGMANN

- Calpeda

- Cooli

- DEBEM

- DEHAHA

- DEKKER

- Dia Pump

- DONGYIN

- Dreno

- DURREX

- Ebara

- EDWIN

- Ekler

- EMSE

- ERDURO

- ETATRON D.S.

- EVP

- Ferroni

- FLOWSERVE

- FLUIMAC

- GARUDA

- GENVAC

- GRACE

- GRUNDFOS

- GÜCÜM

- HAUS

- HERMETICA

- HIDRAULICA U.M. PLOPENI S.A

- Hidrostal

- Hydro-Vacuum

- JEFF

- JESSBERGER

- JOHN CRANE

- Kingda

- KUPAR

- LATTY

- LEO

- Lidering

- LIVERANI

- LOWARA

- M pumps

- Modo

- NASH

- Nettuno

- Noelift

- NOVA ROTORS

- OFT Pumps

- Pall Ring Company

- PANELLI

- Pedrollo

- Pentax

- Prosystem AQUA

- Qeehua

- R&X Energy

- RJCNE

- ROSEN

- ROTEN

- ROVATTI

- ROVER POMPE

- RUUT BLOWER

- SEKO

- Shivay

- SIEMENS

- SOLTEC

- SOYGEN

- Speroni

- Spomasz Zamość

- ST Pompe

- STERLING

- VANE PUMP

- Veneroni

- VFF

- VLAIS

- VULCAN

- Watermot

- Wilo

- XINHONGYUAN

- Yildizsu

- YUY

- Yuzuak

- ZEGOR

- ZENIT

- ZINISAN

- Азовэнергомаш

- КНЗ

- Лидер

- Молдовахидромаш

- МТС-Полтава

- Свердловинні насоси

- Свесский насосный завод

- Укрнасоссервис

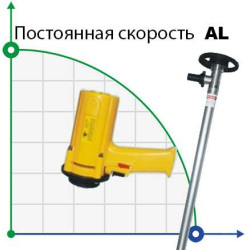

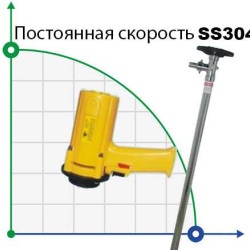

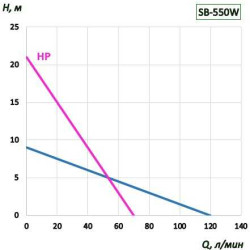

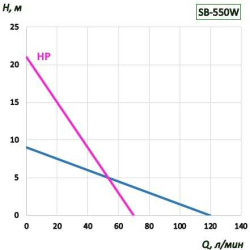

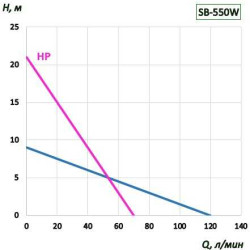

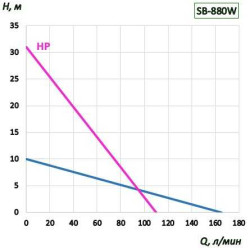

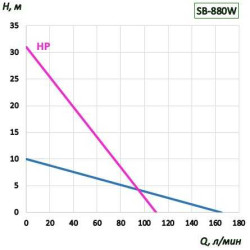

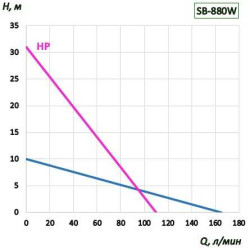

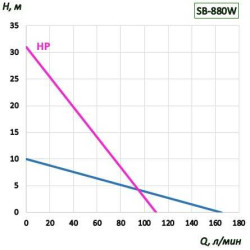

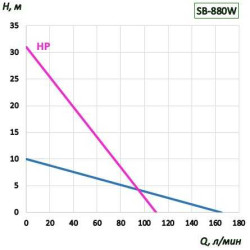

Barrel pumps (with constant speed)

Barrel pumps (constant speed)

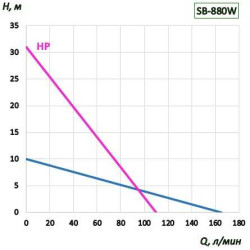

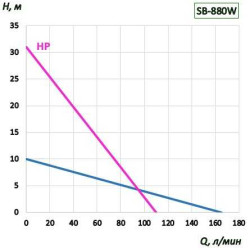

Engine Features:

- Motor Model Meaning: High speed motor.

- Voltage: 220V.

- Speed: 10000rpm

- Frequency: 50-60 Hz.

- Power: up to 1100 W.

Barrel pumps are designed for pumping various types of liquids from canisters, barrels and euro cubes. Barrel pumps are made from various materials such as stainless steel, aluminum, PVC, polypropylene, etc.

Delivery of acids, alkalis and reagents in drums and IBC containers has become common practice. The specified container is most often negotiable, which means that it must be quickly and carefully emptied and returned to the sender. Since bottom-drain containers have become banned in many countries due to the risk of spillage, the only way to drain the liquid has been to use the hole in the lid. Barrel pumps became the most suitable equipment for this work.

Barrel pumps for chemically active liquids sodium hydroxide, acetic, nitric, hydrofluoric acids, hydrochloric acid, nitric acid and others.

Barrel pumps handle nutritional supplements, foodstuffs, molasses, thickeners, flavors, enzymes, liquid concentrates and ingredients. In industry: pumping and unloading reagents and liquids from plastic containers, euro cubes and barrels.

Barrel pumps also pump oil products, solvents, hardeners and other components.