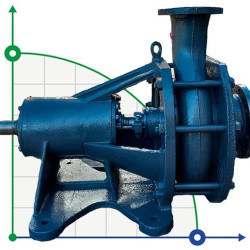

Chemical centrifugal pumps

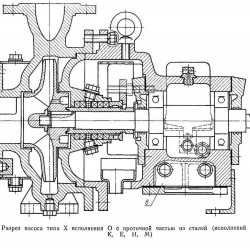

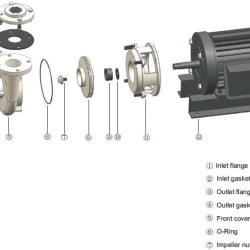

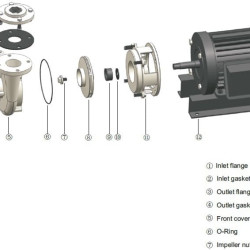

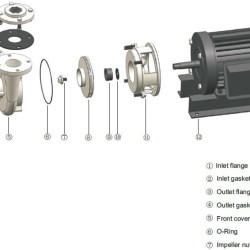

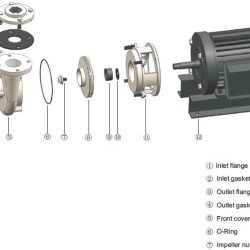

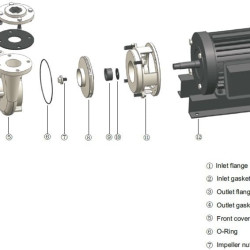

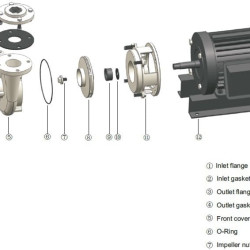

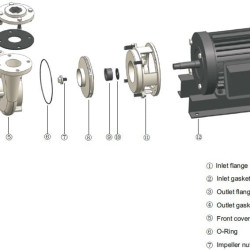

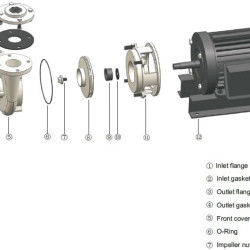

Chemical centrifugal pumps are pumps that have special seals or magnetic couplings in their design to ensure tightness. Such devices are designed to work with chemical liquids, reagents or substances with high alkalinity. Thanks to the high-quality materials at the base of the pump, the device can withstand long loads without deforming parts, which is very popular among users.

Types of centrifugal pumps

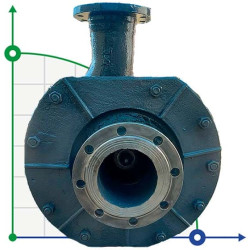

There are many classifications of chemical centrifugal pumps. In general, they are divided into horizontal and vertical according to the direction of work.

In horizontal chemical centrifugal pumps, the shaft is moved horizontally. For vertical - vertically. Thanks to this, you can narrow down the areas of use of devices to individual industries.

You can order any type of pumping equipment from us without overpayments. We will be happy to select a high-quality pump model that will work at your facility and perform all the functions assigned to it.

Advantages of using chemical centrifugal pumps

Be sure to highlight the following advantages of using centrifugal pumps:

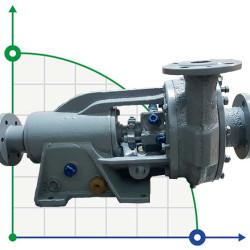

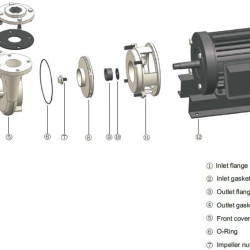

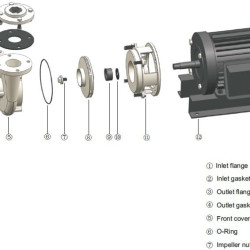

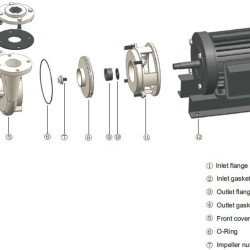

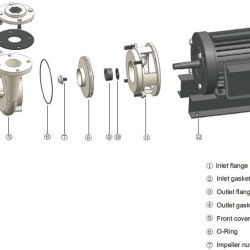

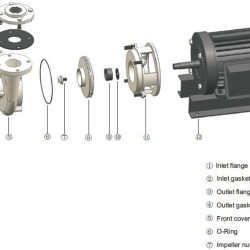

- Simplicity of design;

- Material stability;

- Price;

- Service;

The devices do not require special specialized skills in order to work with them effectively.

Materials for manufacturing are used in a wide variety. This allows you to increase the efficiency of the pump and increase its resistance to chemical influences of various substances.

Compared to other devices, the price of chemical centrifugal pumps remains attractive and affordable.

The simple design makes it easy to carry out technical inspections and repair the device if necessary.

Areas of use of centrifugal chemical pumps.

Since such pumps have increased resistance of materials, it is advisable to use them in industries that require such characteristics. Most often, centrifugal chemical pumps can be found in the production of fertilizers, alcohol, acids, fermentation products, petroleum products, salt solutions, reagents, and food products. In general, the scope of use is limited solely by the user's needs, and therefore centrifugal pumps can be used in all industries. Buying a pump of this type means investing in the structuring of chemical production and its reliability and performance.