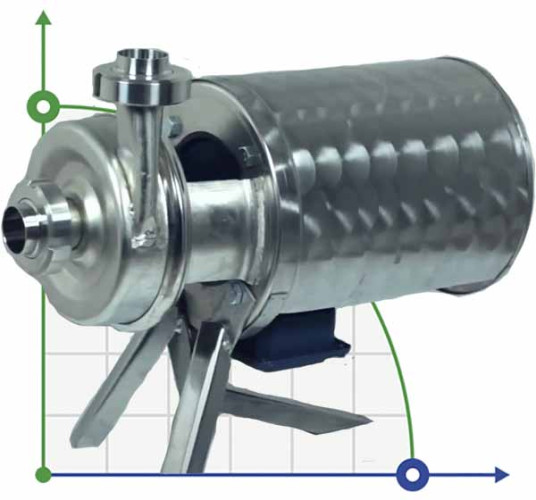

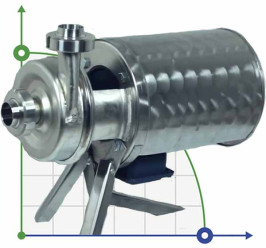

Cheese grain pump G2-OPG, 12,5m3/h, 1,1kW, 380V

Brand:

МТС-ПолтаваCharacteristics

Output pipe diameter:

75 mm

Producer:

MTS-Poltava

Nom.head, m:

3

Power supply:

3х380 V, 50 Hz

Rate of turn, rpm:

930

Feed height, m:

3

Dimensions, mm:

515х297х450

See all

Favorite

Compare

Products from the same category

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Cheese grain pump G2-OPG, 12,5m3/h, 1,1kW, 380V

Output pipe diameter | 75 mm |

Producer | MTS-Poltava |

Nom.head, m | 3 |

Power supply | 3х380 V, 50 Hz |

Rate of turn, rpm | 930 |

Feed height, m | 3 |

Dimensions, mm | 515х297х450 |

Nom.flow rate, m3/h | 12.5 |

Power capacity, kW | 1,1 |

Pump capacity, m3/h | 12.5 |

Impeller diameter, mm | 195 |

Max.temperature, C | 50 |

Input pipe diameter | 75 mm |

Material | AISI 304 stainless steel |

Serial number of the pump | G2-OPG |

Country of Origin | Ukraine |

PumpType | sanitary, hygienic |

Drive Type | electric |

Weight, kg | 41,1 |

Description Cheese grain pump G2-OPG, 12,5m3/h, 1,1kW, 380V

Centrifugal pumps G2-OPG and G2-OPE (special) are designed to pump cheese grain together with whey or water from cheese baths or from cheese makers in forming devices or in the drum for separating whey.

The main parameters of the pump are selected taking into account the minimum mechanical impact on the product in order to preserve the structure and shape of the grain. Therefore, these pumps are designed to create a small pressure and have holes for suction and discharge pipes of large diameters. For the pump to work properly, the suction pipe must be below the level of the product being pumped. The temperature of the product should not exceed 50 ° C.

Productivity of this pump reaches 12,5 cubic meters / h at a pressure of 3 meters of a water column.

The design of the G2-OPG pump is quite simple and consists of a motor (AIR80L4 - 1.1 kW / 1000 rpm), housing, working chamber and legs. The impeller of the G2-OPG pump has five wide blades curved in the opposite direction of rotation and open from the side of the pump cover. The impeller is mounted inside the pump on a tip pressed on the motor shaft and secured with a nut. In turn the pump chamber includes suction and discharge branch pipes with connecting threads of the DN80 sizes (according to the DIN 11851 standard). Also included with connecting threads are conical fittings and cap nuts. Also to avoid leakage of the product during pumping, this pump unit is equipped with an end seal type G2, which provides high tightness of the working chamber by means of a special spring. The tightness of the pump is also ensured by a clamp (special fastening between the chamber and the pump housing), which also provides simplicity and ease of maintenance of the food pump G2-OPG. It should be noted that all materials of the flow part of the pump G2-OPG are made of stainless steel AISI 304 (08Х18Н10) approved for use in the chemical and food industries. The motor is protected from moisture by a casing. The pump is installed without a foundation on three legs.

Cheese grain pump G2-OPG, 12,5m3/h, 1,1kW, 380V reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.