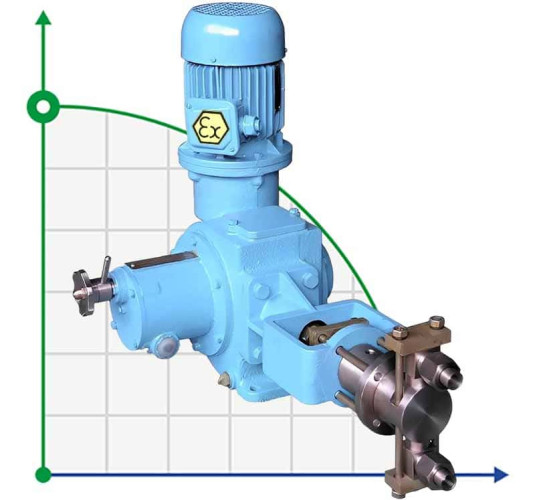

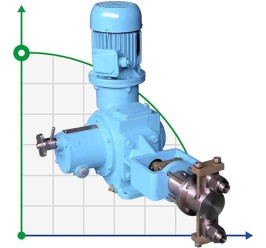

Dosing plunger pump ND 2500/10 D14B, 3 kW, Ex

Brand:

Свесский насосный заводCharacteristics

Producer:

Svessa Pump Plant

Power supply:

3х380 V, 50 Hz

Rate of turn, rpm:

1 500

Operating temperature:

-15°C +150°C

Dimensions, mm:

845x335x792

Power capacity, kW:

3

Explosion protection:

Yes

See all

Documentation

Favorite

Compare

Products from the same category

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Dosing plunger pump ND 2500/10 D14B, 3 kW, Ex

Producer | Svessa Pump Plant |

Power supply | 3х380 V, 50 Hz |

Rate of turn, rpm | 1 500 |

Operating temperature | -15°C +150°C |

Dimensions, mm | 845x335x792 |

Power capacity, kW | 3 |

Explosion protection | Yes |

Seal | chevron cuffs seal |

Flow rate, l/h | 2500 |

Plunger strokes per minute | 100 |

Pressure, bar | 9.8 |

Material of flow channel | AISI 420 |

Material | AISI 420 |

Engine model | AIR 100S4U3; AIM 100S4U2,5 |

Serial number of the pump | ND |

Country of Origin | Ukraine |

PumpType | plunger motor |

Drive Type | electric |

Type of configuration | with engine |

Weight, kg | 203,3 |

Description Dosing plunger pump ND 2500/10 D14B, 3 kW, Ex

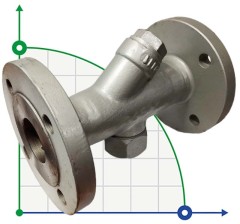

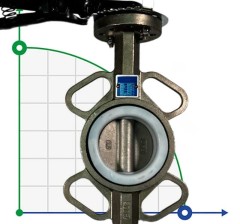

Dosing plunger pumps and units are designed for volumetric pressure dosing of neutral and aggressive liquids, emulsions and suspensions with a density of not more than 1300 kg/m3, with kinematic viscosity fr om 8.5x10-7 to 8x10-4 m2/s (from 0.0085 to 8 St), with a temperature from -15 ºС to +150 ºС, with a solid non-abrasive phase concentration of not more than 10% by weight with a maximum particle density of up to 2000 kg / m3, with a grain size of the solid non-abrasive phase not more than 1% of the nominal diameter of the inlet pipe.

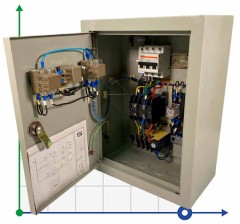

The ND unit consists of a drive and a pump. An electric motor and a geared motor can act as a drive. The pump consists of a single or double movement mechanism and a corresponding number of hydraulic cylinders. The movement mechanism includes a built-in worm gear, a crank mechanism for converting rotational motion into reciprocating motion, and a plunger stroke length adjustment mechanism. The worm gear may be absent (for pumps driven by the balancer of the pumping unit). The hydraulic cylinder consists of a housing, a plunger with a seal, ball valves and connecting pipes.

Implement designation example 2ND 800/63 D14B, wh ere:

2 - the number of plungers (single-plunger - not indicated; 2 - double-plunger);

ND - purpose and design differences:

ND - dosing pump without a heating (cooling) jacket,

NDR - dosing pump with adjustment on the go;

800 - supply, l / h;

63 - pressure at the outlet of the pump, kgf / cm²;

D - execution according to the material of the flow part (steel 20X13 (AISI 420) - D, steel 12X18H10T (AISI 321) - K);

1 - execution according to the type of plunger seal (chevron cuffs - 1, gland packing - 2);

4 - execution according to the design of the plunger seal (without a supply of cooling, sealing or flushing liquid - 3; with a supply of cooling, barrier or flushing liquid - 4);

B - execution according to the degree of explosion protection of the electric motor (general industrial - A, explosion-proof - B).

Documentation Dosing plunger pump ND 2500/10 D14B, 3 kW, Ex

Download instructions, catalog for Dosing plunger pump ND 2500/10 D14B, 3 kW, Ex

Dosing plunger pump ND 2500/10 D14B, 3 kW, Ex reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.