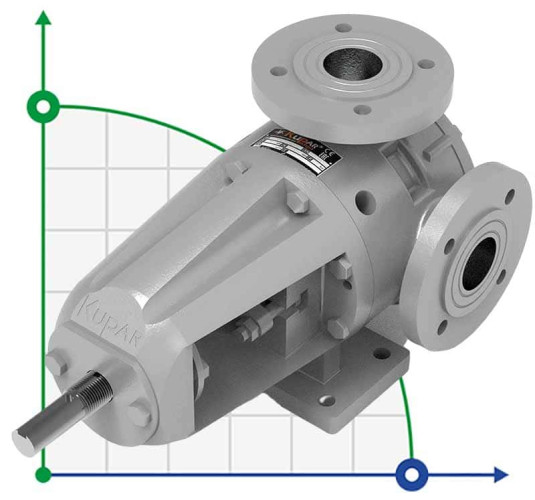

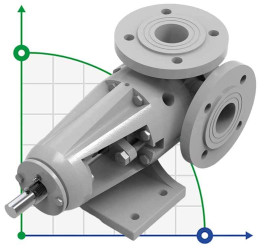

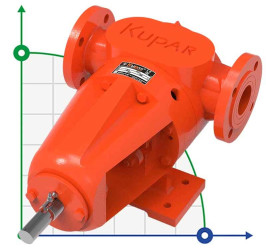

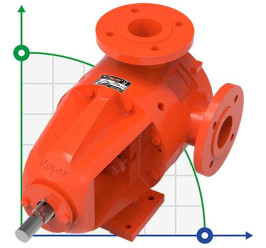

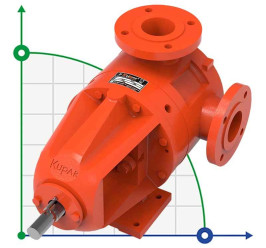

KIP Gear Pump for Thick, Viscous Fluids 1 1/2 C, AISI 316, 0.4-4 m3/h

Brand:

KUPARCharacteristics

Output pipe diameter:

1 1/2"

Producer:

KUPAR

Housing material:

AISI 316 stainless steel

Rate of turn, rpm:

1 000

Operating temperature:

20°C +180°C

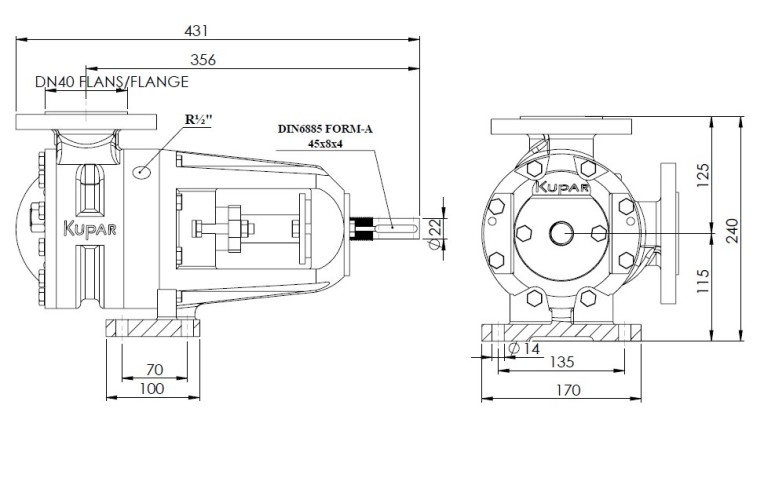

Dimensions, mm:

430x240x170

Flow Rate, L/rev:

0,123

See all

Documentation

Categories

Favorite

Compare

Products from the same category

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures KIP Gear Pump for Thick, Viscous Fluids 1 1/2 C, AISI 316, 0.4-4 m3/h

Output pipe diameter | 1 1/2" |

Producer | KUPAR |

Housing material | AISI 316 stainless steel |

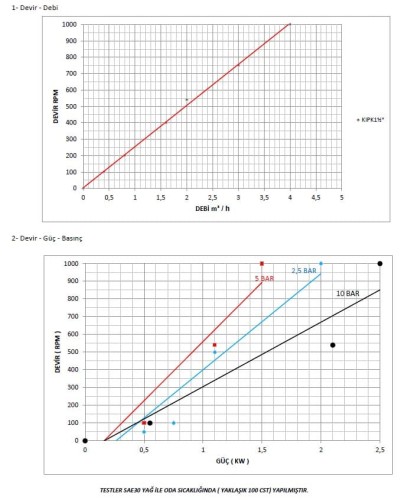

Rate of turn, rpm | 1 000 |

Operating temperature | 20°C +180°C |

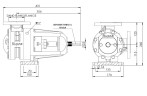

Dimensions, mm | 430x240x170 |

Flow Rate, L/rev | 0,123 |

Max.viscosity, cPs | 25 000 |

Power capacity, kW | 1,5 |

Pressure range, bar | 1-14 |

Pump capacity, m3/h | 3.5 |

Max.flow rate, m3/h | 3.5 |

Gear meshing type | internal |

Input pipe diameter | 1 1/2" |

Material | AISI 316 stainless steel |

Serial number of the pump | KIP |

Country of Origin | Turkey |

PumpType | gear type |

Installation Type | horizontal |

Weight, kg | 16 |

Description KIP Gear Pump for Thick, Viscous Fluids 1 1/2 C, AISI 316, 0.4-4 m3/h

The most important criterion when choosing the type of gear pumps is the viscosity of the product.

The main criteria when choosing a gear pump:

- pump type: the basic principle is that external gear engagement is used for relatively low-viscosity fluids, and internal gear engagement for high-viscosity fluids.

- the size of the nozzles: the size of the nozzles and connecting pipelines are also related to the viscosity of the product. When choosing the type of pump and designing the pipeline system, the diameters of the pipelines should be accurately calculated in order to achieve the optimal flow rate for the liquid of the given viscosity.

In this case, a direct relationship is valid - for liquids with a higher viscosity should be used pipes of a larger diameter.

- pump rotation speed: the maximum speed for gear pumps is 1500 rpm. It decreases as the viscosity increases. High speeds should be chosen for low viscosity, low speeds for high viscosity.

The direct clutch with the electric motor is used at 1000 and 1500 rpm. For 500 rpm. and below - clutching with the electric motor is carried out through a gearbox or V-belt transmission.

-operational tolerances: operating clearances are set during pump manufacturing, some clearances are adjusted during pump assembly, according to viscosity ranges.

To pump a certain type of liquid, you should use a pump with appropriate working clearances, otherwise the pump may work with less pressure or stop completely.

Documentation KIP Gear Pump for Thick, Viscous Fluids 1 1/2 C, AISI 316, 0.4-4 m3/h

Download instructions, catalog for KIP Gear Pump for Thick, Viscous Fluids 1 1/2 C, AISI 316, 0.4-4 m3/h

KIP Gear Pump for Thick, Viscous Fluids 1 1/2 C, AISI 316, 0.4-4 m3/h reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.