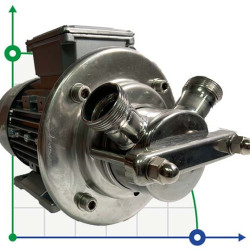

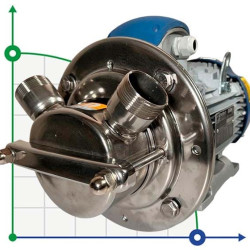

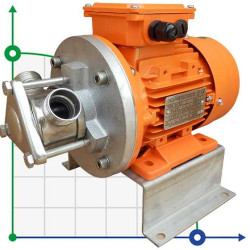

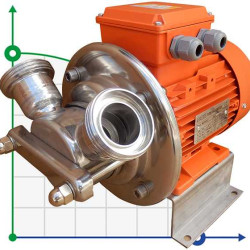

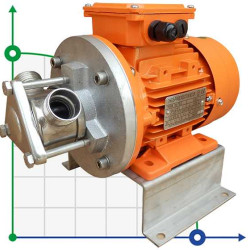

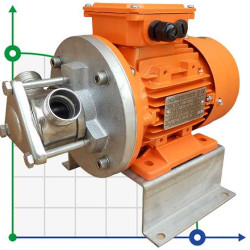

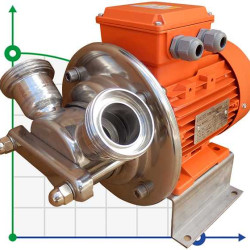

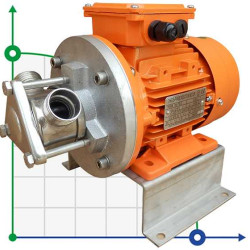

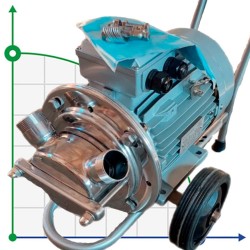

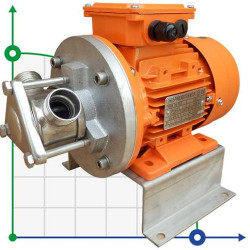

Impeller pumps

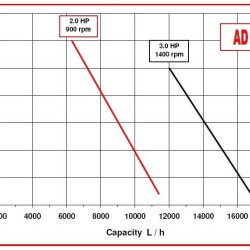

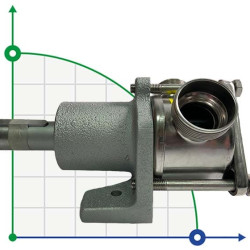

Impeller pumps are devices that allow you to pump water using a special working part - a flexible implant. Such a pump harmoniously combines the advantages of both volumetric pumps and dynamic pumps. Thanks to modern engineering solutions, impeller pumps can effectively supply water to already developed systems, or design new water supply networks based on them. The principle of operation of the pump is quite simple - when the working part is rotated by an electric motor, a high-pressure zone is formed on one side of the flexible petals. A low-pressure zone is formed on the opposite side. The mixture or liquid enters the housing, is sucked into the high-pressure part, and is fed into a pressure hose or pipe. Thus, the movement of products inside occurs. The speed of transportation depends on the selected power of the impeller pump.

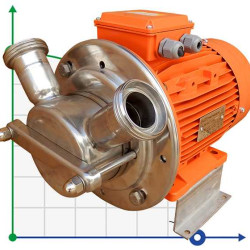

Advantages of impeller pumps

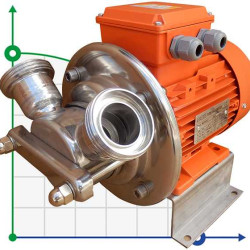

The implant pump is used in cases where smooth operation is required during pumping liquids. Due to its design features, the device can work with viscous liquids and transport them without any problems. Other advantages include:

- Availability of the possibility of "dry" suction;

- Smooth and gradual pumping of products that require increased care during transportation;

- Good efficiency and economical power consumption;

- High reliability and safety during operation;

- Easy operation and technical support;

- Versatility;

- Relatively low price.

And this is not all the features that affect the choice of users. Impeller pumps are a really effective way to provide the system with a source of liquid pumping. To order a pump, please contact our managers. We will help you choose the right model that will perform the tasks assigned to it and will be able to meet all your requirements.

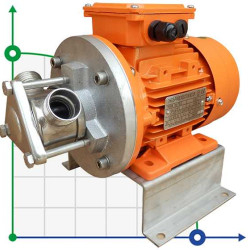

Where are impeller pumps used?

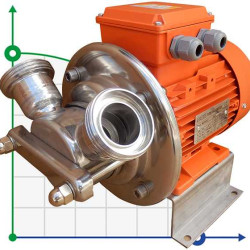

Most often, impeller pumps can be found in:

- Food industry;

- The cosmetics industry;

- Oil refining industry;

- Pharmaceuticals;

They are used for pumping dough, baking creams, syrups, dairy products, honey, raw materials for cooking or other products of similar consistency.

It is used for transportation of finished products or raw materials

It is used for transportation of petroleum products, gasoline, resins, kerosene or other similar goods.

It is used for transporting ready-made medicines or individual reagents.