AlphaDynamic AD30/01/TR/DRP 0.75kW impeller pump on a trolley, with dry running protection

Brand:

AlphaDynamicCharacteristics

Output pipe diameter:

G 1 1/4"

Producer:

AlphaDynamic

Dry running protection:

Yes

Power supply:

3х380 V, 50 Hz

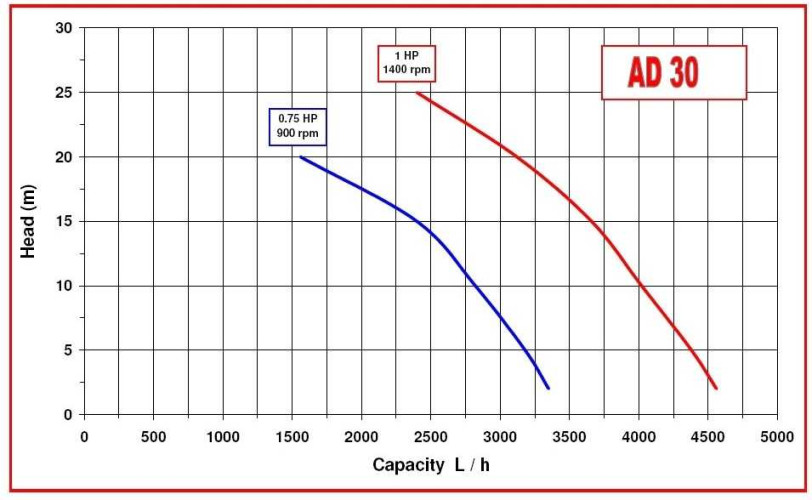

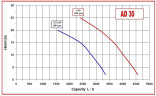

Max. head, m:

25

Rate of turn, rpm:

1 400

Feed height, m:

25

See all

Documentation

Categories

Favorite

Compare

Products from the same category

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

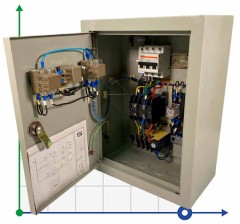

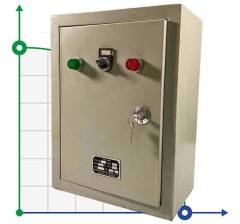

On-line payment on the sitePayment is made by bank cardsFeatures AlphaDynamic AD30/01/TR/DRP 0.75kW impeller pump on a trolley, with dry running protection

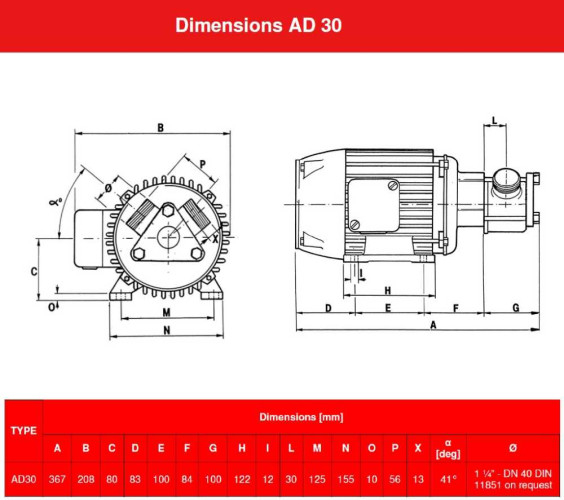

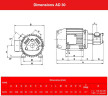

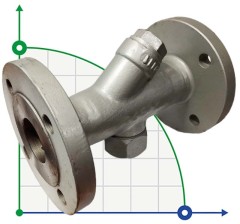

Output pipe diameter | G 1 1/4" |

Producer | AlphaDynamic |

Dry running protection | Yes |

Power supply | 3х380 V, 50 Hz |

Max. head, m | 25 |

Rate of turn, rpm | 1 400 |

Feed height, m | 25 |

Model | AD30 |

Power capacity, kW | 0,75 |

Pump capacity, m3/h | 4.5 |

Max.flow rate, m3/h | 4.5 |

Max.temperature, C | 90 |

Input pipe diameter | G 1 1/4" |

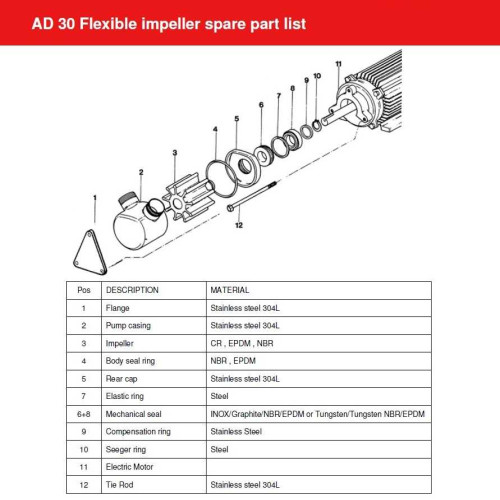

Material | AISI 304 stainless steel |

Availability of a mobile cart | Yes |

Serial number of the pump | AD |

Country of Origin | Greece |

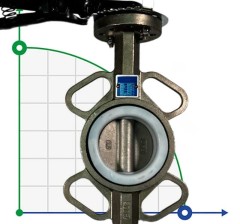

PumpType | flexible impeller |

Drive Type | electric |

Installation Type | horizontal |

Type of configuration | with engine |

Availability of spare parts | Yes |

Warranty, months | 12 |

Application | paints, food and drink, Sahara, graze, butter, wine processing products, extracts, ink, lotion, cheese masses, liquid soap, fruit puree with berries, oils, guilt, chocolate, yogurt, honey, shampoo, glue, cream |

Description AlphaDynamic AD30/01/TR/DRP 0.75kW impeller pump on a trolley, with dry running protection

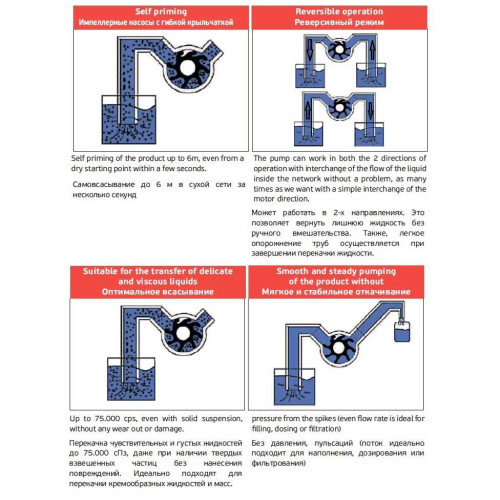

The AD series flexible impeller pumps are widely used in the food and beverage industry for liquids such as honey, sugar, paste, butter, yogurt, chocolate, butter, wine, wine products, extracts, etc. In the paint and varnish industry for liquids such as ink, paints, glue. In the cosmetic industry and in the manufacture of pharmaceutical products: lotion, cream, shampoo, liquid soap.

The principle of operation of an impeller pump with a flexible impeller is quite simple - due to the displacement of the axis of rotation of the impeller (impeller, impeller) relative to the working chamber, the flexible blades of the impeller alternately pressing and moving away from the walls of the chamber create a vacuum on one side and a zone of increased pressure on the opposite side.

Due to the use of a flexible impeller, the pump creates a smooth laminar flow of liquid, allows the pump to be started without preliminary filling ("dry suction"), allows you to gently pump products without destroying the structure (cheese masses, fruit purees with berries, etc.)

Benefits

- suction from a depth of up to 5 meters, without preliminary filling;

- reverse mode;

- constant and stable pumping;

- the possibility of pumping viscous liquids, and liquids with solid suspensions;

- body material - stainless steel;

- monoblock design for greater strength and tightness;

- easy cleaning and replacement of the impeller and mechanical seal;

- the flexible impeller is completely made of non-toxic materials (neoprene, NBR, EPDM) and is resistant to various chemically active compounds;

- impellers made of neoprene and EPDM meet the requirements of the FDA for the control of fluids related to food products;

- mechanical seal made of INOX / GRAPHITE / NBR / EPDM or Tungsten / Tungsten / NBR / EPDM;

Documentation AlphaDynamic AD30/01/TR/DRP 0.75kW impeller pump on a trolley, with dry running protection

Download instructions, catalog for AlphaDynamic AD30/01/TR/DRP 0.75kW impeller pump on a trolley, with dry running protection

AlphaDynamic AD30/01/TR/DRP 0.75kW impeller pump on a trolley, with dry running protection reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.