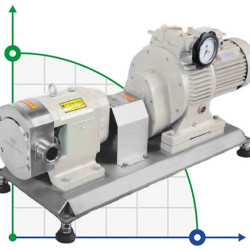

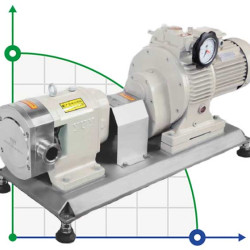

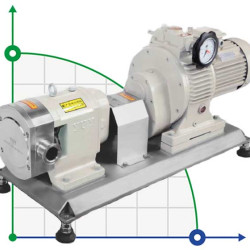

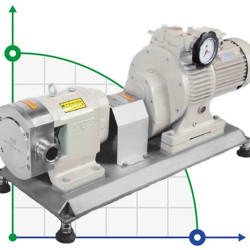

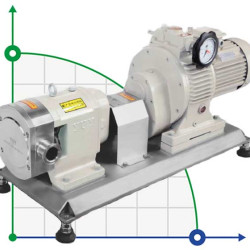

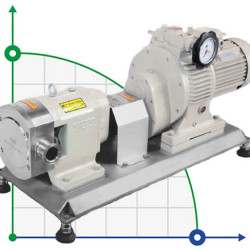

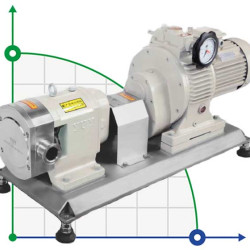

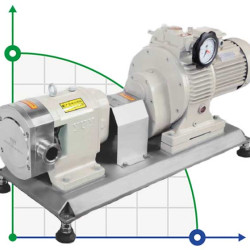

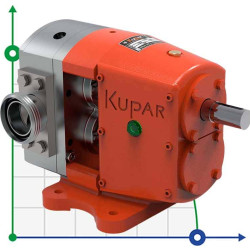

Cam pumps

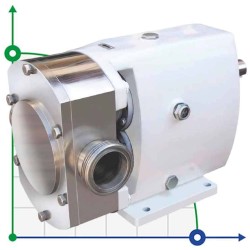

A cam pump is a pump that does not have stagnant zones. All its internal parts are almost sterile, well polished and suitable for use during food transportation. The design of the device is quite complex, but it meets the quality standards achieved through the use of appropriate certified materials during production. All surfaces of the cam pump are treated in order to meet sanitary standards and maintain a high service life along with economy, productivity and reliability. The increased complexity of the design and thoroughness during production can affect the price of the cam pump, but its subsequent maintenance is not so expensive.

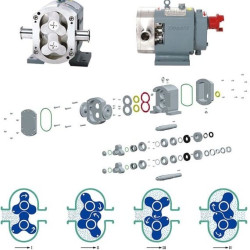

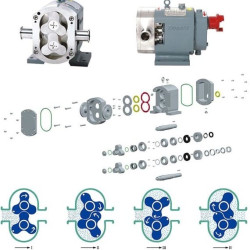

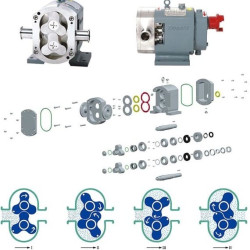

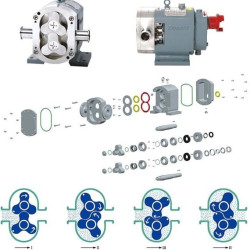

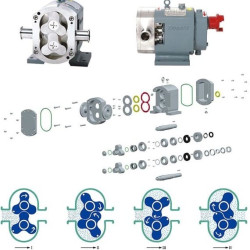

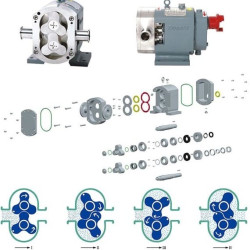

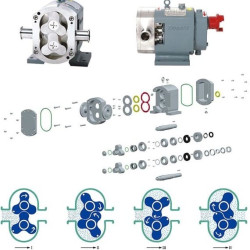

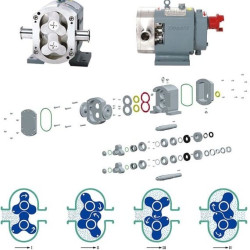

Operating principle of Cam pumps

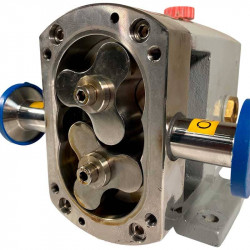

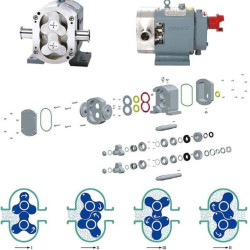

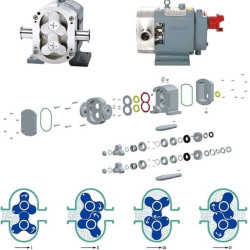

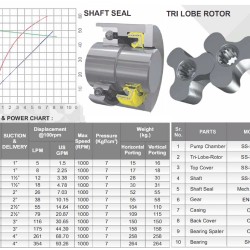

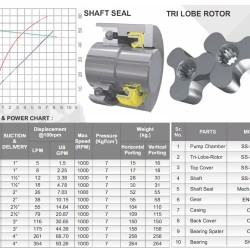

The main part of the cam pump is represented by two rotors that rotate inside the housing and do not touch each other. They also do not interact with the pump walls. During the operation of the rotors, the pumps inside are gradually filled with liquid. The mixture passes through the pump from the suction pipe to the discharge pipe. The return flow is minimal, as the gap between the rotors is very small and precise to ensure continuous fluid flow. This increases the efficiency of the entire device and the speed of Transportation.

Advantages of using cam pumps

Cam pumps are mainly used in the food or pharmaceutical industry. They are powerful enough to perform all the necessary functions and allow you to maintain the necessary cleanliness during Operation. In addition, users highlight the following advantages of using a cam pump:

- Easy operation and maintenance;

- Availability of all necessary certificates for production facilities that require compliance with hygiene standards;

- Reliable design and the possibility of long-term daily use without wear and tear;

- Ability to transport viscous and thick mixtures;

- Ability to modify and change configurations to improve system performance;

- Possibility of pumping in both directions;

- High power.

Due to its versatile design, Cam pumps can be used in many industries. The variability of models allows you to choose the right device that will perform all the tasks assigned to it. Be sure to contact our specialists for more information about Cam pump models to buy pumping equipment with the necessary technical characteristics.