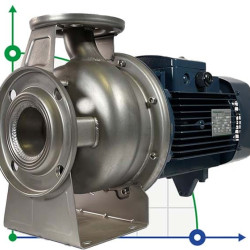

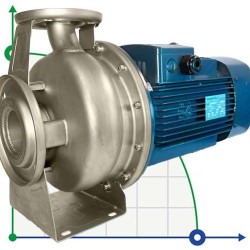

Monoblock stainless steel pumps

Application

- Water supply

- Heating

- Ventilation and air conditioning

- Increasing pressure

- Heating systems

- Refrigeration and refrigeration systems

- Irrigation

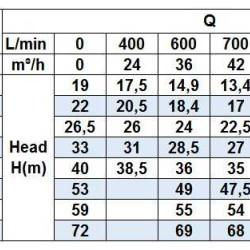

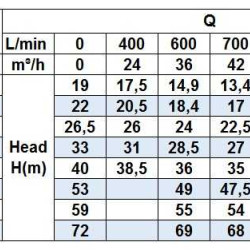

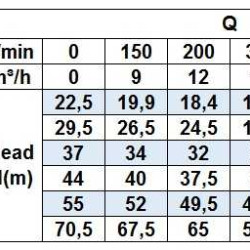

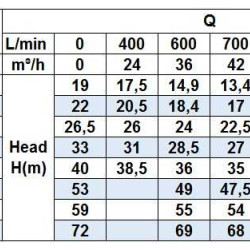

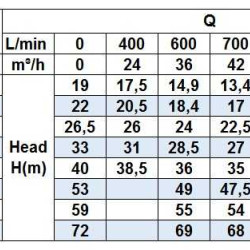

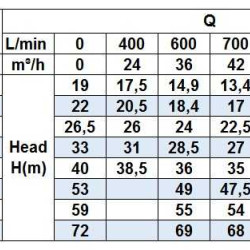

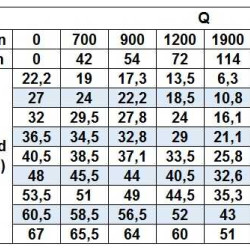

Performance

Monoblock centrifugal pumps SM are designed for use in heating, cold and hot water supply, air conditioning, as well as for other industrial applications.

- head 55 m,

- productivity 72 m³/h,

- maximum working pressure 10 bar,

- maximum temperature of the pumped liquid 120°С,

- Wet end material: stainless steel AISI 304, AISI 316.

Monoblock centrifugal pumps SM are designed for pumping water, as well as any liquids similar to it in chemical composition, density and consistency. In addition, pumps can pump liquids of greater density than water, with the presence of suspended particles (for example: post-alcohol stillage, mash).

The traditional areas of operation of devices such as SM are heating and water supply (both hot and cold). The function with which monoblock pumps cope perfectly is maintaining the pressure at the desired level (for example, interfloor).

SM centrifugal pumps have shown themselves well in the alcohol industry, namely for pumping stillage, mash.

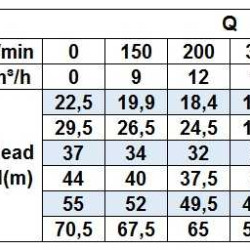

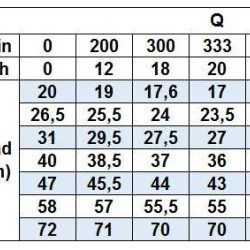

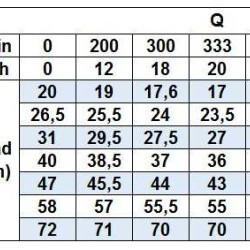

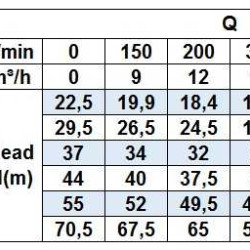

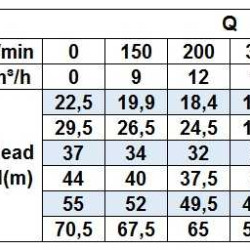

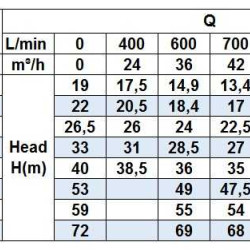

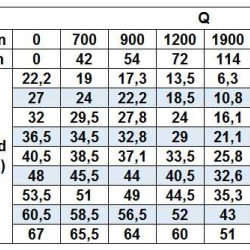

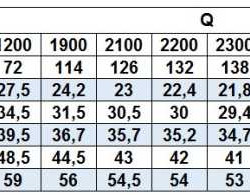

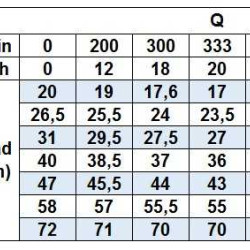

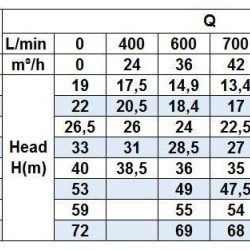

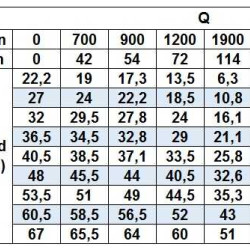

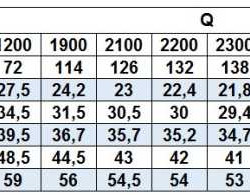

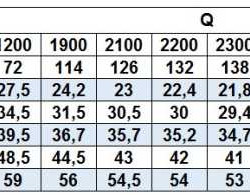

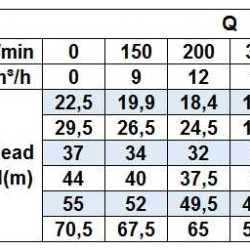

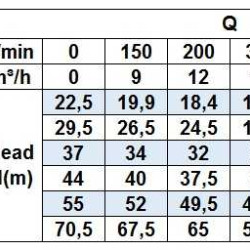

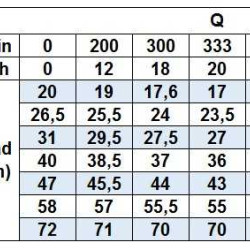

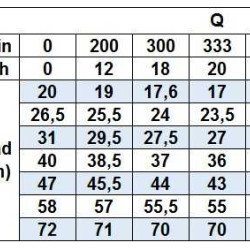

Performance charts

Material specification

| Pump casing | Stainless steel AISI 304, AISI 316 |

| pump shaft | |

| Working wheel | |

| mechanical seal | Graphite/Ceramic/NBR (Standard) Graphite/Ceramic/Viton (chemical version) |

SM pump design

| 1 Pump housing | 5 Impeller | 9 flange | 13 Electric motor |

| 2 Bolt | 6 Mechanical seal | 10 Nut | 14 Stand |

| 3 Impeller nut | 7 O-ring | 11 Bolt | |

| 4 Spring washer | 8 Pump cover (bottom) | 12 Key |

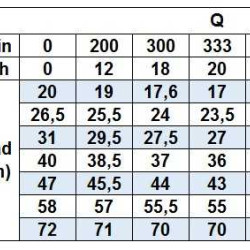

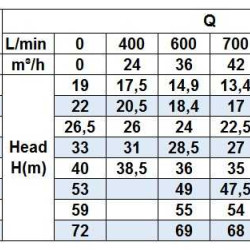

Characteristic table

| Model (GB5662) |

Model (DIN24255) |

Power | Q | l/min | fifty | 100 | 150 | 200 | 250 | 300 | 333 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 800 | 1000 | 1200 |

| kW | m3/hour | 3.0 | 6.0 | 9.0 | 12 | fifteen | eighteen | twenty | 24 | 27 | thirty | 33 | 36 | 39 | 42 | 48 | 60 | 72 | |||

| 50-32-160/2.2 | 50-32-160/2.2 | 2.2 |

Head (m) |

26 | 25.5 | 25 | 24 | 23.5 | 21.5 | twenty | eighteen | ||||||||||

| 50-32-160/3.0 | 50-32-160/3.0 | 3.0 | 35 | 34 | 33 | 32 | 31 | thirty | 29 | 27 | |||||||||||

| 50-32-200/4.0 | 50-32-200/4.0 | 4.0 | 40.5 | 40 | 38.5 | 37.5 | 36 | 34 | 33 | thirty | |||||||||||

| 50-32-200/5.5 | 50-32-200/5.5 | 5.5 | fifty | 49.5 | 49 | 48.5 | 48 | 47.5 | 47 | 44.5 | |||||||||||

| 65-50-125/2.2 | 65-40-125/2.2 | 2.2 | 15.5 | fifteen | 14.5 | fourteen | 13 | 12 | eleven | ten | eight | 6 | |||||||||

| 65-50-125/3.0 | 65-40-125/3.0 | 3.0 | 21.8 | 21.5 | 21.3 | 21.1 | 20.7 | 20.2 | 19.5 | 18.4 | 16 | 14.5 | 12.5 | ||||||||

| 65-50-160/4.0 | 65-40-160/4.0 | 4.0 | 28.5 | 28 | 27.4 | 27.1 | 26.3 | 25.4 | 24.3 | 22.9 | 21.7 | 20.5 | 19 | ||||||||

| 65-50-160/5.5 | 65-40-160/5.5 | 5.5 | 36 | 35 | 34.5 | 33.8 | 33 | 32 | 31.5 | 31 | 30.5 | 29.8 | 29 | ||||||||

| 65-40-200/7.5 | 65-40-200/7.5 | 7.5 | 44.5 | 43.5 | 42.5 | 42 | 41.8 | 41 | 40 | 38.5 | 37 | 35 | 33 | ||||||||

| 65-40-200/9.2 | 65-40-200/9.2 | 9.2 | 53.5 | 52.8 | 52 | 51.5 | 51 | 50.5 | fifty | 49.5 | 49 | 47 | 45.5 | ||||||||

| 80-65-125/4.0 | 65-50-125/4.0 | 4.0 | 21.6 | 21.2 | 20.5 | twenty | 19.2 | 18.2 | 17.5 | 15.5 | eleven | eight | |||||||||

| 80-65-125/5.5 | 65-50-125/5.5 | 5.5 | 25.6 | 25.4 | 24.9 | 24.5 | 23.8 | 23.3 | 22.6 | 21 | 19 | fourteen | |||||||||

| 80-65-160/7.5 | 65-50-160/7.5 | 7.5 | thirty | 29.8 | 29.5 | 28.8 | 28 | 27 | 26.5 | 24.8 | 23 | 19 | |||||||||

| 80-65-160/9.2 | 65-50-160/9.2 | 9.2 | 37 | 36.5 | 36 | 35.3 | 34.5 | 34 | 33.8 | 32 | thirty | 27.5 | |||||||||

| 80-50-200/11 | 65-50-200/11 | eleven | 52 | 51 | fifty | 49.5 | 49 | 48.5 | 48 | 46 | 41 | 33 | |||||||||

| 80-50-200/15 | 65-50-200/15 | fifteen | 55 | 54.8 | 54.5 | 54.3 | 54 | 53.5 | 51 | 51 | 46.8 | 40 | |||||||||