Pneumatic diaphragm pumps

Pneumatic diaphragm pumps are devices that are used to work with viscous and thick liquids. The principle of operation of the device is based on vibrations of the membrane from the air flow supplied from a pneumatic drive. Due to the membrane, liquids are pumped in the desired direction into the pressure pipe. This engineering solution allows you to work more efficiently with chemically aggressive and thick liquids without the risk of overheating or overloading the device.

Advantages of using pneumatic diaphragm pumps.

Users highlight the following advantages of using pneumatic pumps:

- Mobility;

- Convenient installation and easy installation;

- Safety and reliability;

- Ability to work without liquid in the system;

- Suction pump;

- Adaptability;

- Possibility of pumping liquids with solid impurities;

- Relatively low price;

- Simplicity, durability and safety;

The pump is not heavy, compact. It can be easily carried and installed in already equipped systems.

To start the device, simply connect the main hoses and hoses to it and fix the device.

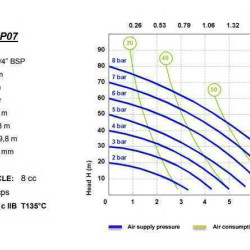

The only parameter that needs to be monitored is the system pressure. The device starts immediately after the air supply. The maximum pressure values can be viewed in the technical characteristics of the device, since they are different for each model.

Diaphragm pumps do not deform from idle operation

The membranes are capable of creating a vacuum and lifting the liquid to a height of up to 8 meters

Diaphragm pumps can work equally efficiently with a wide variety of liquids

The membranes are resistant to mechanical damage

Compared to other similar devices that produce similar capacities and speeds, diaphragm pumps have a lower and more attractive price.

The devices are reliable and can last a long time without regular repairs. Parts can be easily replaced and the pump can be restored.

Areas of use of pneumatic diaphragm pumps

Most often, such devices are purchased to work with binders or liquids where solid particles are present. Accordingly, diaphragm pumps have found their application in:

- Oil refining industry;

- Chemical industry;

- Food industry;

- Pharmaceuticals;

- Agriculture;

- Cooling systems;

- Heating systems.

There are virtually no restrictions on the use of diaphragm pumps. It all depends on the user's needs and the specifics of their project. In order to choose the best model of pumping equipment, please contact our specialists.