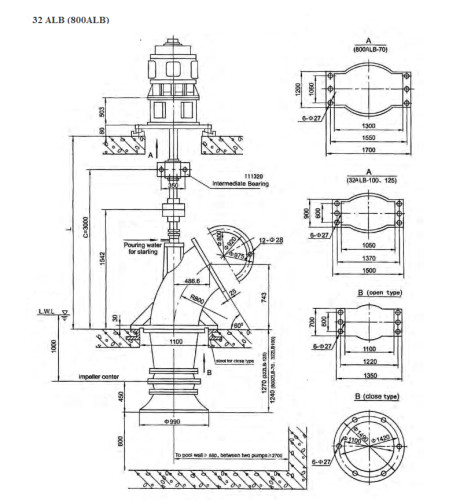

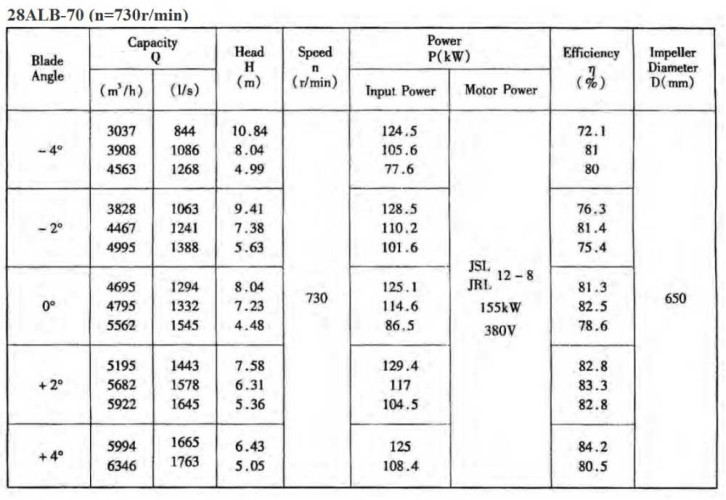

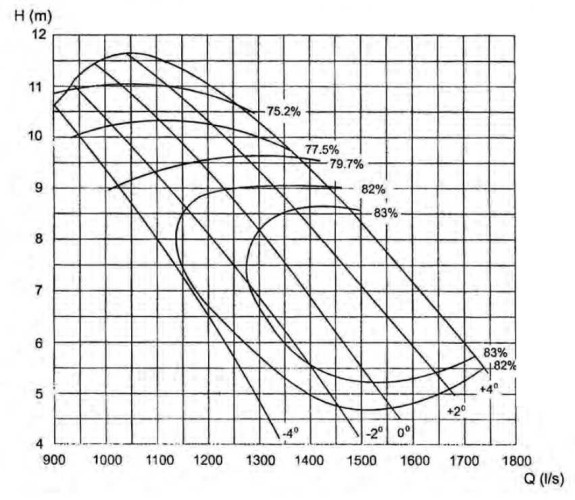

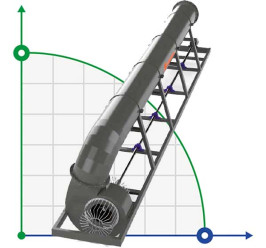

Axial pump 28ALB-70, 5000 m3/h, 155 kW (without motor)

Brand:

BTS EngineeringCharacteristics

Producer:

BTS Engineering

Nom.head, m:

7.2

Feed height, m:

7.2

Nom.flow rate, m3/h:

5000

Power capacity, kW:

155

Pump capacity, m3/h:

5000

Material:

cast iron

See all

Categories

Favorite

Compare

Products from the same category

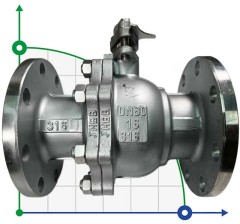

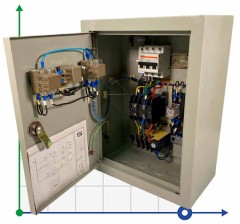

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Axial pump 28ALB-70, 5000 m3/h, 155 kW (without motor)

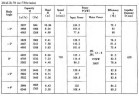

Producer | BTS Engineering |

Nom.head, m | 7.2 |

Feed height, m | 7.2 |

Nom.flow rate, m3/h | 5000 |

Power capacity, kW | 155 |

Pump capacity, m3/h | 5000 |

Material | cast iron |

Serial number of the pump | ALB |

PumpType | axial |

Drive Type | electric |

Warranty, months | 12 |

Description Axial pump 28ALB-70, 5000 m3/h, 155 kW (without motor)

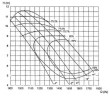

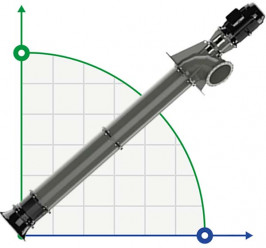

Axial pumps are intended mainly for the supply of large volumes of liquids. Their work is due to the transfer of the energy that the liquid receives when the frontal surface of the rotating blades of the impeller is forcefully exposed to it. At the same time, the particles of the supplied liquid have curved trajectories, but after passing through the straightening apparatus, they begin to move from the entrance to the pump to the exit from it, mainly along its axis (hence the name).

There are 2 main types of axial pumps: rigid-bladed with blades fixed motionlessly on the impeller sleeve, called propeller, and rotary-bladed, equipped with a mechanism for changing the angle of inclination of the blades. Pumps of both varieties are usually built single-stage, less often two-stage.

A distinctive feature of axial pumps is the design and operation of the impeller. It consists of a sleeve on which several blades are fixed, representing a conveniently streamlined curved wing with a twisted front edge running into the flow. When the blade profile is moved, caused by the rotation of the impeller, in the liquid, due to a change in the velocity of its flow along the lower and upper surfaces of the profile, the pressure above the profile should increase, and under the profile - decrease. This creates a pump head.

Axial pump 28ALB-70, 5000 m3/h, 155 kW (without motor) reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.