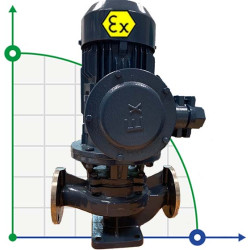

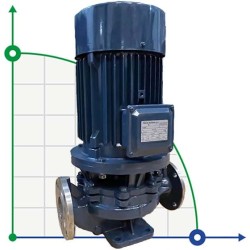

Pumps in-line

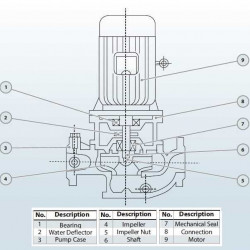

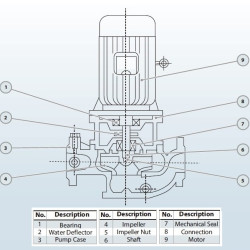

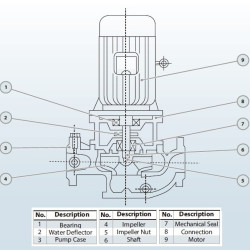

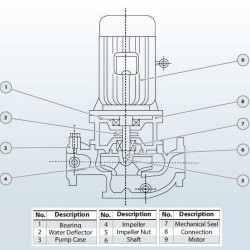

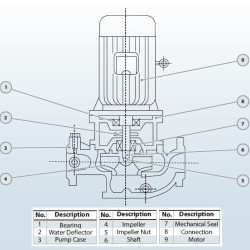

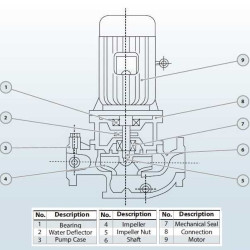

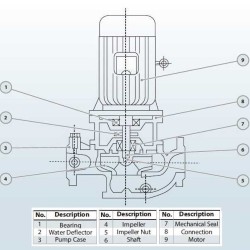

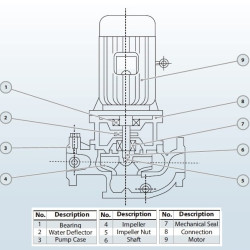

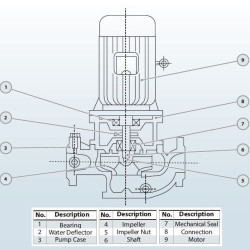

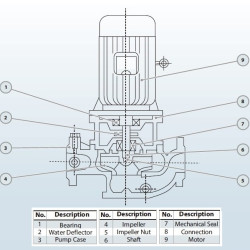

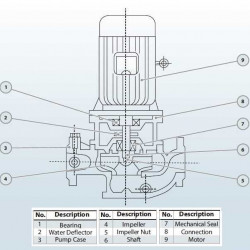

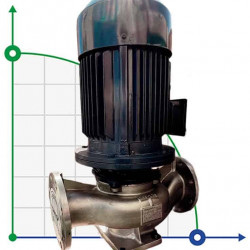

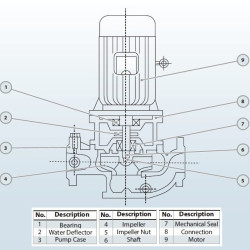

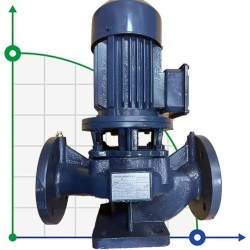

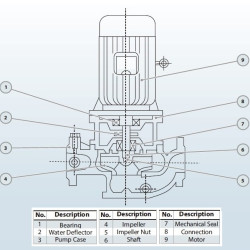

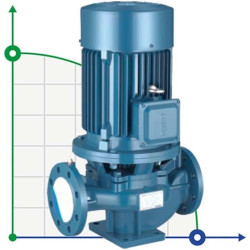

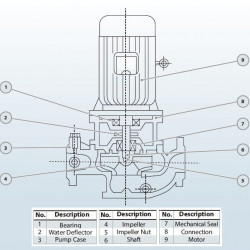

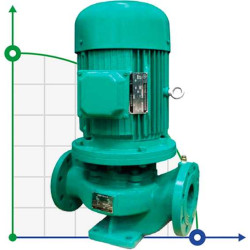

In-line pumps are devices that allow you to transport water with high pressure. Most often, such devices are used for cooling systems or for pumping aggressive media. The fundamental difference between such pumps is the absence of liquid contact with the rotor of the product. A mechanical seal is often used here to insulate the housing from the pump shaft. The device is installed "in line", which determines the name of the pump type - in-line. Thanks to this, you can easily remove the housing with the working Housing and the electric motor without removing the device from the entire network. This allows for more flexible pump settings and makes maintenance easier and more cost-effective.

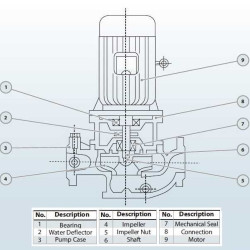

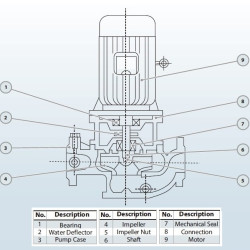

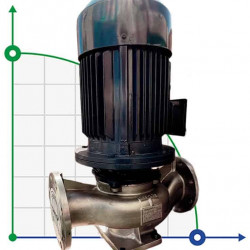

Design features of in-line pumps

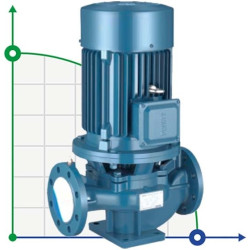

As already mentioned, the main feature is that this type of pump is mounted in one line with the pipes. The entire design of the device is monoblock, parts are easily replaced and serviced. The location of the suction and pressure pipes allows you to increase the speed of water passage through the system. To maintain optimal power, in - line pumps are equipped with flanged electric motors with air cooling. Due to this, in-line pumps are most often used to equip water supply systems in apartment buildings or industrial facilities. They are installed on the pipeline and can provide the necessary capacity, saving the remaining resources. Brackets in the project can be used to strengthen the stability of the pipeline. Less often, the pump can be mounted on special concrete pallets or foundations.

Where inline pumps are used

Most often, inline pumps are used in networks where it is necessary to ensure a good liquid pressure. These can be:

- Heating or air conditioning systems;

- Circulation systems;

- Water or non-aggressive liquid pumping systems on an industrial scale;

- Mass irrigation systems;

- Pressure boosting systems;

- Cooling systems;

- Fire extinguishing systems;

- Various technological systems.

The scope of use of inline pumps is limited exclusively to the needs of users. In order to choose the right model, be sure to contact our specialists. We will help you find the best pump that will accurately perform the tasks assigned to it.