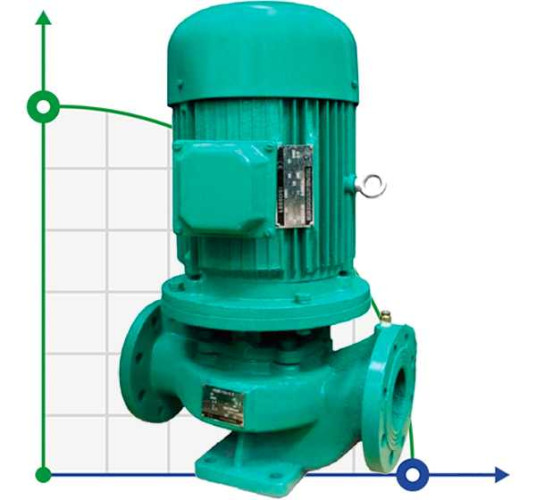

IRG 200-315 (I) Centrifugal pump

Brand:

BTS EngineeringCharacteristics

Output pipe diameter:

DN200

Producer:

BTS Engineering

Nom.head, m:

32

Power supply:

3х380 V, 50 Hz

Feed height, m:

32

Nom.flow rate, m3/h:

400

Power capacity, kW:

55

See all

Documentation

Favorite

Compare

Products from the same category

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures IRG 200-315 (I) Centrifugal pump

Output pipe diameter | DN200 |

Producer | BTS Engineering |

Nom.head, m | 32 |

Power supply | 3х380 V, 50 Hz |

Feed height, m | 32 |

Nom.flow rate, m3/h | 400 |

Power capacity, kW | 55 |

Pump capacity, m3/h | 400 |

Explosion protection | No |

Nom.pressure, Mpa | 1,6 |

Max.temperature, C | 120 |

Material of flow channel | cast iron |

Input pipe diameter | DN200 |

Material | cast iron |

Serial number of the pump | IRG |

Country of Origin | China |

PumpType | in-line |

Drive Type | electric |

Installation Type | vertical |

Availability of spare parts | Yes |

Warranty, months | 12 |

Application | heating, circulation, drying, glaze, cooling towers, ice water, recycling water supply, drying chamber, water, pressure increase |

Analogue for | AlfaLaval, Kenle, Honda, Hobart, Hilge, Hidrostal, Grundfos, GEA, KOLMEKS, Johnson, Ebara, Inoxpa, HYPRO, Hydro-Vacuum, Omnigena, Odwerk, Nocchi, LOWARA, KSB, Alweller, SIHI, Rovatti, ALLWEILER, ASTA, Aquatechnika, Aquario, APV, Varna, Flygt, DPPumps, DAB, Cornell, Caprari, Calpeda, Bronzoni, FRISTAM, Foras, Kripsol, PERKINS, Sterling, Pentax, PentairSwimmey, Packo, Onga, Svanehoj, Sprut, Speroni, SOMA, Simaco, SAER, WILO, VARISCO, Unitech, ThuneEureka, TEREX, TAJFUN, Greenpumps, OMAC, Zenit |

Description IRG 200-315 (I) Centrifugal pump

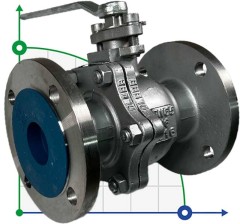

Dry motor pumps of IRG Series are vertical in-line single stage centrifugal pumps. Such kind of body design makes them more resistant to mechanical inclusions contained in feed medium in comparison to the similar pumps with “wet” rotor. “In-line” construction of the pump makes it possible to perform in-place pump dismounting without dismantling the elements of pipeline system.

Documentation IRG 200-315 (I) Centrifugal pump

Download instructions, catalog for IRG 200-315 (I) Centrifugal pump

IRG 200-315 (I) Centrifugal pump reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.