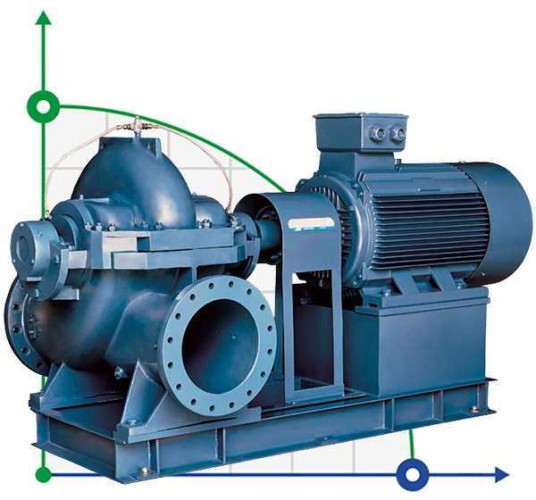

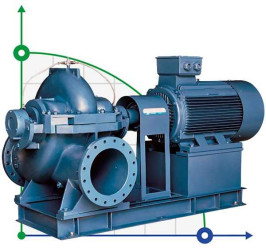

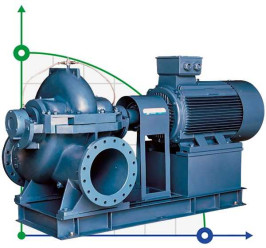

BSSM4 350-590A1, (1000) - double-sided inlet pump unit, analogue of D 4000-95A-2

Brand:

BTS EngineeringCharacteristics

Output pipe diameter:

DN350

Producer:

BTS Engineering

Impeller material:

cast iron

Power supply:

6000 V

Max. head, m:

4000

Rate of turn, rpm:

1 000

Feed height, m:

4000

See all

Documentation

Categories

Favorite

Compare

Products from the same category

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures BSSM4 350-590A1, (1000) - double-sided inlet pump unit, analogue of D 4000-95A-2

Output pipe diameter | DN350 |

Producer | BTS Engineering |

Impeller material | cast iron |

Power supply | 6000 V |

Max. head, m | 4000 |

Rate of turn, rpm | 1 000 |

Feed height, m | 4000 |

Power capacity, kW | 1 250 |

Pump capacity, m3/h | 90 |

Max.flow rate, m3/h | 90 |

Input pipe diameter | DN500 |

Material | cast iron |

Country of Origin | China |

PumpType | two-way entrance |

Drive Type | electric |

Type of configuration | with engine |

Warranty, months | 12 |

Description BSSM4 350-590A1, (1000) - double-sided inlet pump unit, analogue of D 4000-95A-2

The BSCM double-sided inlet pump unit, an analogue of the D 4000-95A-2 pumps, is suitable for pumping liquids that do not contain solid inclusions by weight of more than 0.05%, size of more than 0.2 mm, microhardness of more than 6.5 GPa (650 kgf / mm2), is not chemically aggressive with respect to the materials from which the pump is made.

Materials:

body - cast iron with anti-corrosion coating;

shaft - chrome-plated steel;

seals - mechanical seal.

Pumps with a detachable housing are recommended for use in water supply systems, sewage treatment plants, pressure boosting plants, fire extinguishing plants, irrigation, for water circulation in air conditioning systems, agriculture.

The main difference between BSCM type pumps and other centrifugal pumps is the feature of fluid supply to the impeller. Suction occurs in such a way that the liquid enters the impeller of the blade type from both sides. Physically, this is done in order to compensate for the axial force, which, in the case of a one-way fluid supply, affects the impeller in one direction. With insignificant pump parameters, it does not matter. Therefore, pumps of this type are designed specifically for tasks where the pump must have high performance.

The second advantage of the two-way inlet pumps is that they have suction and discharge pipes arranged so that the liquid is supplied and discharged horizontally, and not at an angle of 900, as is done in most centrifugal pumps.. This advantage lies in the fact that it is easier to install such pumping units.

Another advantage of the design of the BSCM two-way inlet pumps is that the pump part is easily disassembled - the upper cover is bolted, and not poured entirely as a single body, it happens in almost all models of centrifugal pumps. This makes it possible to repair and maintain the pumping part on site without dismantling the unit from the pipeline.

Documentation BSSM4 350-590A1, (1000) - double-sided inlet pump unit, analogue of D 4000-95A-2

Download instructions, catalog for BSSM4 350-590A1, (1000) - double-sided inlet pump unit, analogue of D 4000-95A-2

BSSM4 350-590A1, (1000) - double-sided inlet pump unit, analogue of D 4000-95A-2 reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.