Screw pumps

Screw pumps are pumps that have a special design based on the use of a screw to transport substances. Due to their specific structure, as well as special engineering solutions, such devices can quickly and efficiently pump liquids of various viscosities, acidity and aggressiveness. Thanks to this feature, the devices are widely used both for industry and in everyday life.

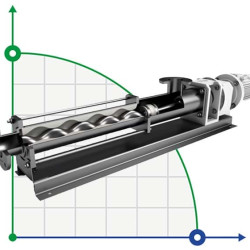

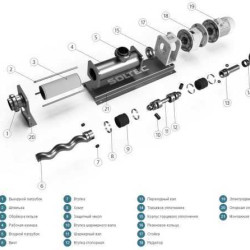

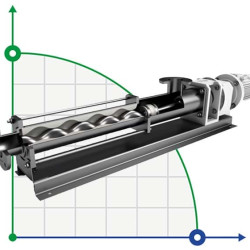

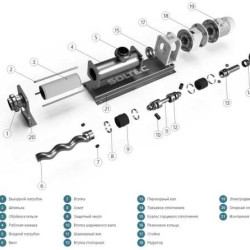

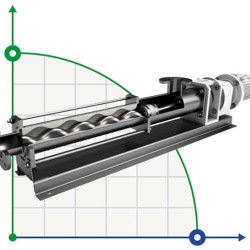

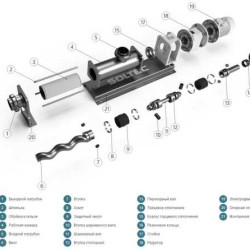

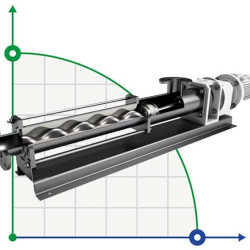

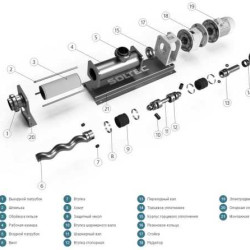

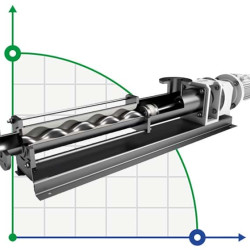

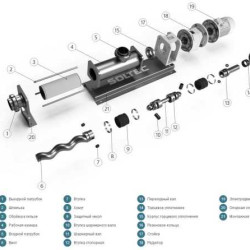

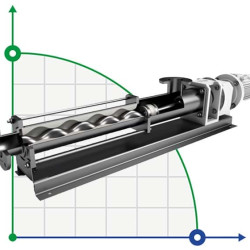

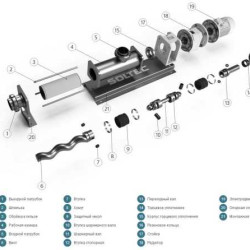

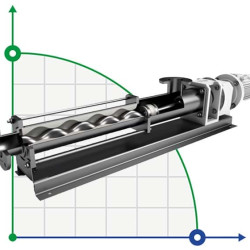

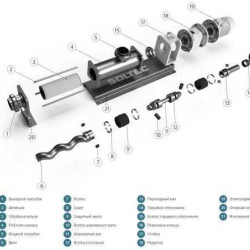

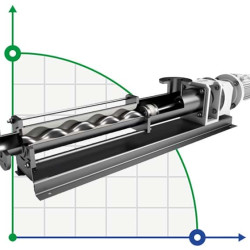

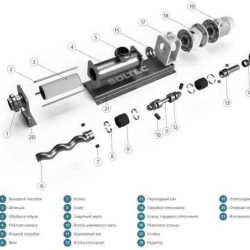

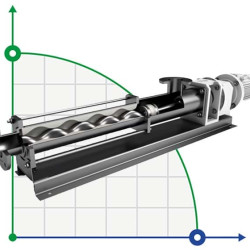

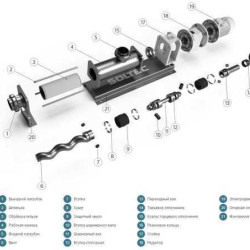

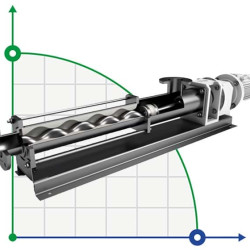

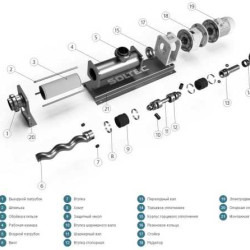

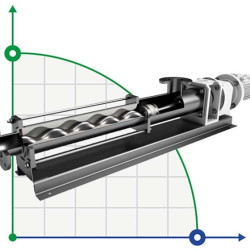

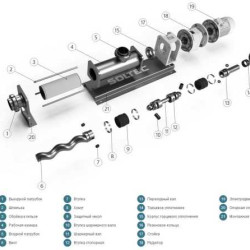

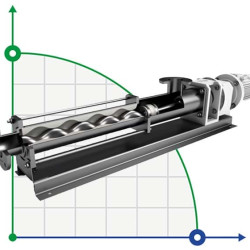

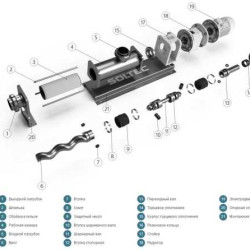

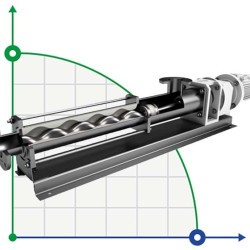

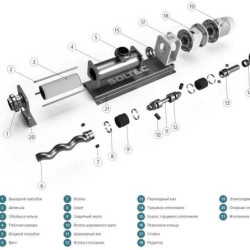

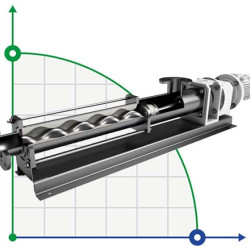

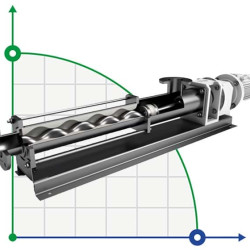

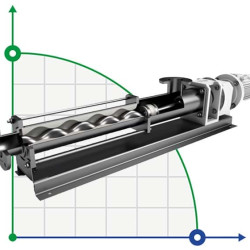

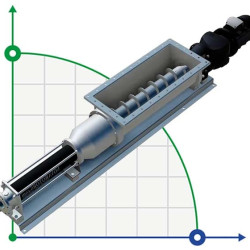

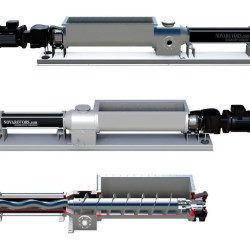

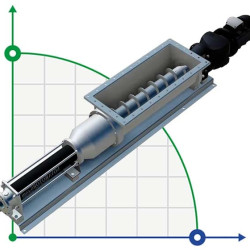

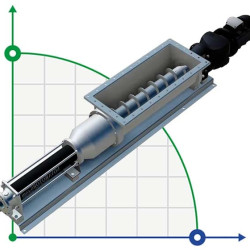

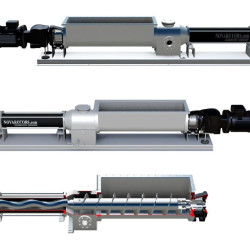

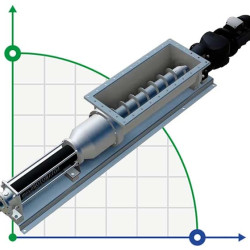

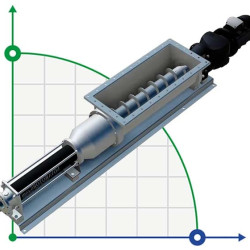

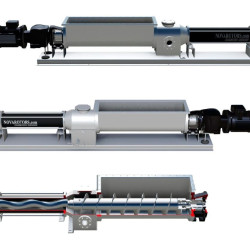

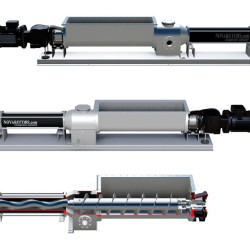

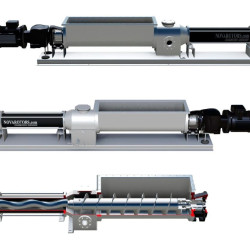

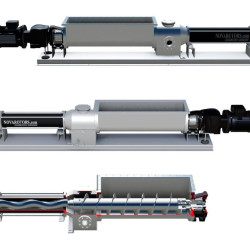

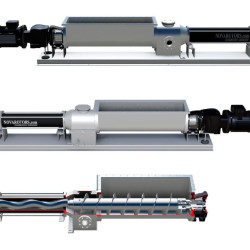

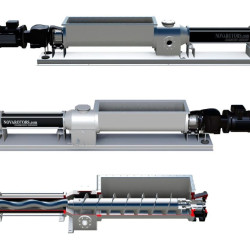

Screw pump design

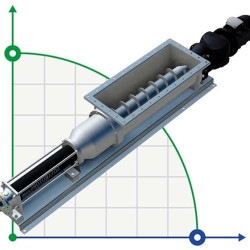

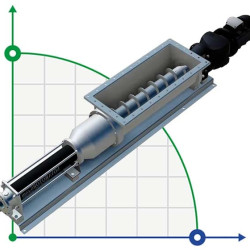

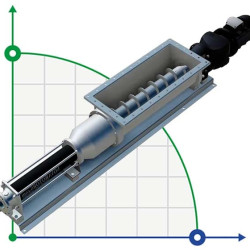

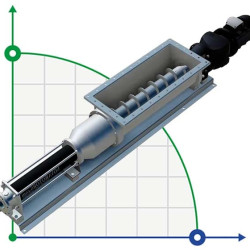

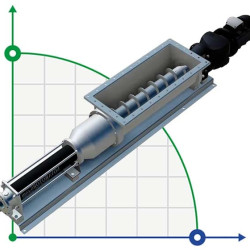

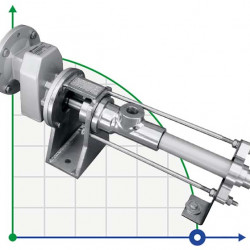

The screw pump is based on the principle that the pressure of the pumped liquids is created due to their displacement by rotors that are made of metal. They rotate inside the elastomer stator. Scrolling of the rotors is provided on the principle of a screw, that is, they rotate creating open and closed areas alternately. Thus, the liquid is transported along this axis, and since all this happens in a confined space, the liquid cannot move in the opposite direction. Thus, the speed and efficiency of the system remains very high, even despite the density of the product.

Screw pumps can be single-screw, double-screw or three-screw depending on the number of screws in the structure. The efficiency and power of the pump depends on the number of screws. Also, to a certain extent, screws are responsible for the service life, since with more screws, you can evenly distribute the load and extend the service life of parts.

Areas of use of screw pumps

Screw pumps are really efficient. High performance of screw pumps is achieved due to a well-developed design, as well as materials at the base of the device. The device has gained its popularity in the following industries:

- Construction projects;

- The paper industry;

- Oil refining industry;

- Chemical industry;

- Food industry;

- Pharmaceuticals;

It is used for pumping concrete, resins, various solutions of roofing and bulk nature

It is used for pumping glue, cellulose, and bleaching solutions.

It is used for pumping oil, fuel oil, kerosene, paraffin or waste.

It is used for pumping aggressive and toxic liquids that require increased resistance of materials.

It is used for pumping dairy products, batter, syrups or other liquid food products.

It is used for pumping medicines.

Before you buy a screw pump, it is better to consult our managers, who will help you choose the right device model at an affordable price.