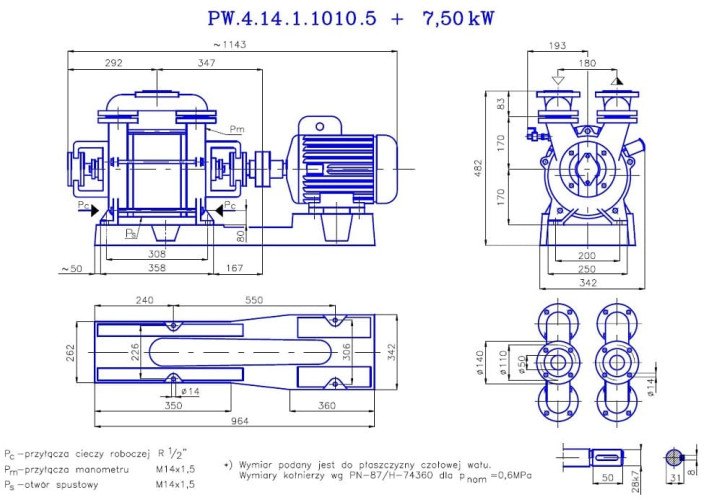

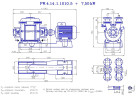

PW.4.14.1.1010 single-stage vacuum pump

Brand:

Hydro-VacuumCharacteristics

Producer:

Hydro Vacuum

Housing material:

Сast iron

Impeller material:

bronze

Power supply:

3х380 V, 50 Hz

Rate of turn, rpm:

1 500

Power capacity, kW:

7,5

Pump capacity, m3/h:

240

See all

Categories

Favorite

Compare

Products from the same category

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures PW.4.14.1.1010 single-stage vacuum pump

Producer | Hydro Vacuum |

Housing material | Сast iron |

Impeller material | bronze |

Power supply | 3х380 V, 50 Hz |

Rate of turn, rpm | 1 500 |

Power capacity, kW | 7,5 |

Pump capacity, m3/h | 240 |

Explosion protection | No |

Seal | Packing 608 type |

Max.flow rate, m3/h | 240 |

Shaft material | AISI 420 |

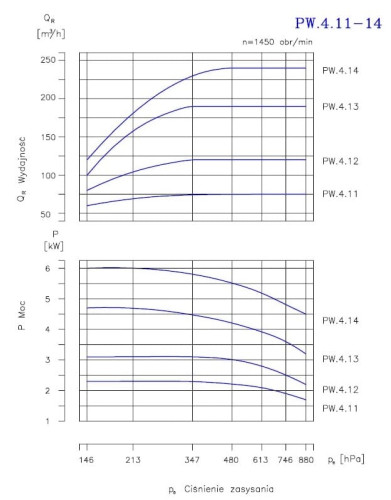

Vacuum depth, mBar | 146 |

Material | cast iron |

Serial number of the pump | PW |

Country of Origin | Poland |

PumpType | vacuum |

Drive Type | electric |

Installation Type | horizontal |

Type of configuration | with engine |

Application | autoclave, residues, evaporators |

Analogue for | Italvacuum, ВВН, Вакууммаш, Sterling, Robuschi, Pompetravaini TRM, Nitto, EVP, Elmo rietschle, Becker, Busch, DVP |

Weight, kg | 192 |

Description PW.4.14.1.1010 single-stage vacuum pump

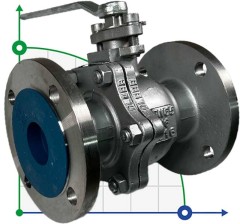

Water-ring vacuum pumps of the PW1 – 12-PW7-14 series are single-stage vacuum pumps. Vacuum pumps are designed for suction and pumping of dry gas with a temperature of up to 150°C and vapor-saturated gases, characterized in that their temperature does not exceed 100°C, with the possibility of using working fluids with a viscosity of up to 60 mm2 / sec and a density of 800-1200 kg/m3, the water temperature at the pump outlet should not exceed 80°C. Hydro-Vacuum produces single-stage and two-stage vacuum water ring pumps, PW series. In the PW series pumps, the pump and the motor are mounted on a common support. The torque from the motor is transmitted to the impeller through a shaft mounted in the support bearings and an elastic coupling. This design makes the vacuum pump noticeably longer and heavier, but it significantly facilitates its maintenance when it is necessary to disassemble the pump or replace the engine. In addition, the pump is mounted on 2 supports (the impeller between the bearings), which gives a much longer service life of the pumps than a monoblock (mounted on the motor shaft or the landing of the impeller)

Standard material design of pumps: pump body, links-cast iron 250; rotor-tin bronze B101; shaft-steel 2H13 (AISI 420).

If the customer needs and wishes, the material execution may be different. The housings are chrome-plated cast iron, tin-plated bronze, carbon cast steel, austenitic cast steel; The rotor is spheroidal cast iron, austenitic cast steel, carbon cast steel, special austenitic cast steel. The shaft is acid-resistant steel. Each pump can be complete with different engines (kW) in terms of power, if the customer needs, we make the selection individually.

PW.4.14.1.1010 single-stage vacuum pump reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.