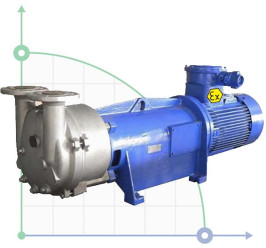

Vacuum pump SK-20 with engine

Brand:

BTS EngineeringCharacteristics

Producer:

BTS Engineering

Flow, l/min:

85

Rate of turn, rpm:

980

Power capacity, kW:

37

Pump capacity, m3/h:

1200

Explosion protection:

No

Max.flow rate, m3/h:

1200

See all

Documentation

Categories

Favorite

Compare

Products from the same category

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures Vacuum pump SK-20 with engine

Producer | BTS Engineering |

Flow, l/min | 85 |

Rate of turn, rpm | 980 |

Power capacity, kW | 37 |

Pump capacity, m3/h | 1200 |

Explosion protection | No |

Max.flow rate, m3/h | 1200 |

Vacuum depth, mBar | 33 |

Material | cast iron |

Serial number of the pump | SK |

PumpType | vacuum |

Drive Type | electric |

Type of configuration | with engine |

Application | evaporators, residues, autoclave |

Analogue for | EVP, ВВН, Вакууммаш, Sterling, Robuschi, Nitto, Italvacuum, Elmo rietschle, DVP, Busch, Becker |

Description Vacuum pump SK-20 with engine

Water ring vacuum pump – for this type of pump only water can be used as the transferred liquid. Vacuum water ring pump works in systems non-soluble noble gases pumping, aggressive gases or just for air depression (vacuum production). “Water ring” – means that the transferred liquid is water. Wide range of usage refers to versatility of device and its service properties. Oil, chemical, paper, construction, mining, metallurgic medical industries and so on. The arrangement of assembly unit and working chamber doesn’t need lubrication or additional vacuum pumps. This reduces the costs of expendables for customer. Rotor is located coaxial to motor and has proportional form. This prevents from out-of-balance operation and provides well-behaved long-term.

All the important splits in working chamber are awash while pump operating. The consequence of this is the absence of friction between working parts, and the result – ruggedness and endurance.

Our company always makes the researched in domain of energy saving and has a lot of feed arrays regarding water ring vacuum pumping units.

Water ring vacuum pumping equipment had a high level of reliability, durability and profitability, that is why it perfectly approves itself in different industries and spheres, the main of which are:

• Chemical industry: distillation, crystallization of tinct compositions and agricultural fertilizers; the biogenous solvent drying, man-made fiber, amino plastics, polyethylene materials; dissipation, sorbing of toxic gases and hazardous fluids; vacuum, dipping in manufactory process of condensers, electromotors, conductors, transformer plants, etc.

• Wood-working and pulp industry: productions runs for wood drying and converting, vacuum filtration and production of cellulose, production of pulp and paper materials, etc.

• Metallurgic industry: the appliance of water ring vacuum pumps in production runs, connected with powder metallurgy; the production of superconductors, ultrapure connections, laser crystals, etc.

• Machine industry;

• Food industry: the production of brewer’s malt, dehydrofreezing of food substances, fractionation of alcoholic beverages, demineralization of water medium, moisture boil-od in sugar production, etc.

• Optics: vacuum aluminizing of mirror-like surfaces; fading of optical equipment, etc;

• Pharmaceutical industry: crude drugs clearance, pharmaceutical drugs production and storage, etc.

• Building industry: degasification of ceramic and argillaceous raw materials and so on.

• Perfume and cosmetics production.

The suction absolute pressure can reach 33 mbar (vacuum degree 97%). When the vacuum pump always works in the condition that the gas pressure is below 80 mbar, cavitation protection tube is supposed to be linked. If air ejector is equipped, the suction pressure can reach 10mbar. The ejector can be installed directly on the pump. Worked as a compressor, 2BV pump’s highest pressure can reach 0.26 Mpa (absolute pressure).

Water rings vacuum pump are divided into three main types:

• Water ring vacuum pump single- phased, with one working chamber (monocoque)

• Water ring vacuum pump single-phased, with two working chambers

• Water ring vacuum pump two-phased, with two working chambers

Water ring vacuum pump and compressors are widely used in petrochemical engineering, medicine, food, sugar industry and other areas. In the gas compression process, the temperature is constant and that is why 2BV pumps can be used for pumping explosion hazard gases.

Documentation Vacuum pump SK-20 with engine

Download instructions, catalog for Vacuum pump SK-20 with engine

Vacuum pump SK-20 with engine reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.