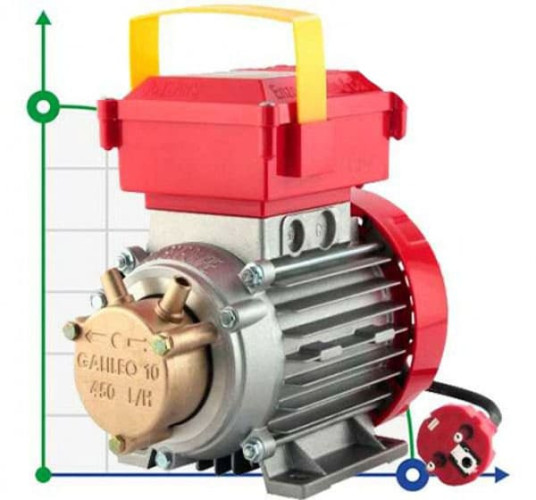

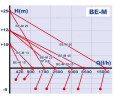

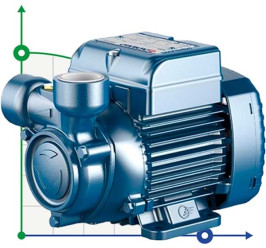

BE-M 10 liquid ring pump

Brand:

ROVER POMPECharacteristics

Output pipe diameter:

10 mm

Producer:

ROVER POMPE

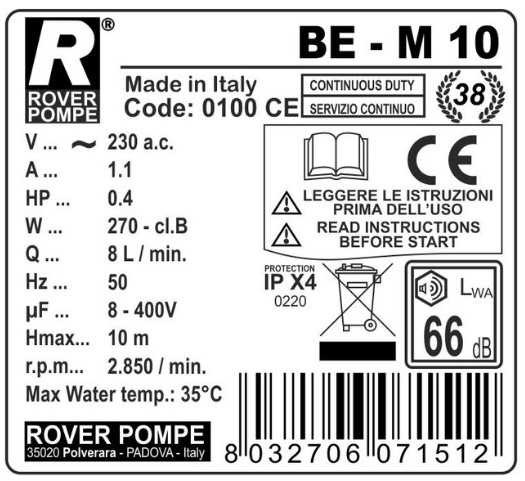

Power supply:

1х220 V, 50 Hz

Max. head, m:

10

Rate of turn, rpm:

3 000

Feed height, m:

10

Dimensions, mm:

210x120x190

See all

Documentation

Categories

Favorite

Compare

Products from the same category

Also buy with this product

Exchange or returnWe will return or exchange for another product

Exchange or returnWe will return or exchange for another product Fast shippingWe will pick up and send promptly

Fast shippingWe will pick up and send promptly Warranty and qualityGuaranteed return of goods within 10 days

Warranty and qualityGuaranteed return of goods within 10 days On-line payment on the sitePayment is made by bank cards

On-line payment on the sitePayment is made by bank cardsFeatures BE-M 10 liquid ring pump

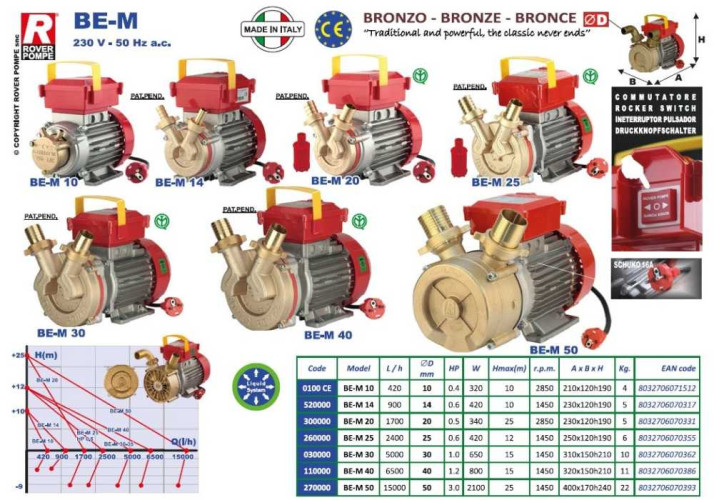

Output pipe diameter | 10 mm |

Producer | ROVER POMPE |

Power supply | 1х220 V, 50 Hz |

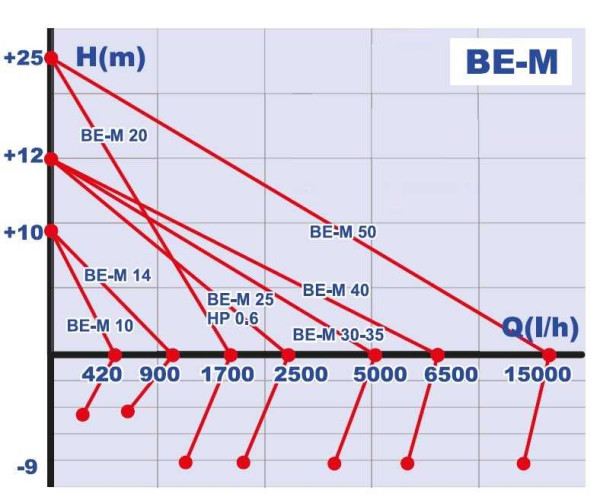

Max. head, m | 10 |

Rate of turn, rpm | 3 000 |

Feed height, m | 10 |

Dimensions, mm | 210x120x190 |

Model | BE-M 10 |

Power capacity, kW | 0,3 |

Pump capacity, m3/h | 0.42 |

Max.flow rate, m3/h | 0.42 |

Input pipe diameter | 10 mm |

Material | bronze |

Serial number of the pump | BE-M |

Country of Origin | Italy |

PumpType | vortex |

Drive Type | electric |

Type of configuration | with engine |

Warranty, months | 12 |

GTIN | 8032706071512 |

Weight, kg | 4 |

Description BE-M 10 liquid ring pump

Application: pump for juice, milk, whey, pumping wine, wine material, beer, wort, syrup, water, emulsion and oil.

Self-priming liquid ring pump with a star-shaped impeller, equipped as standard with a double direction of rotation and a high-efficiency motor designed for continuous operation. The special hydraulic geometry allows the pump to operate even in the presence of air bubbles in the intake fluid.

The liquid ring pump provides suction capacity by simply filling the pump body through one of the hose holders. the suction power is active in both directions of rotation.

The pump can be used to pump any type of ordinary liquid that does not need to be chemically aggressive or abrasive. Some examples: water, wine, milk, vinegar, low-viscosity oil solutions, neutral liquid detergents, diesel fuel. The viscosity of the liquid should not exceed 4 sP for continuous operation with free flow and should not exceed 20 sP for periodic operation with free flow and the presence of an operator for observation.

Routine maintenance requires a small number of simple interventions, as if it were a normal household appliance. After use, drain clean water to flush the inner surfaces of the pump. The electric motor does not require maintenance, there are no parts for lubrication. The outer parts must be cleaned with a slightly damp sponge, and then immediately dried with a cloth.

Documentation BE-M 10 liquid ring pump

Download instructions, catalog for BE-M 10 liquid ring pump

BE-M 10 liquid ring pump reviews

Help in selection

+38 067 360-71-01

Selection of mechanical seals

+38 095 656-37-57

Pump selection

If you have any questions when placing an order, or need help choosing a product, please contact the specified contacts.