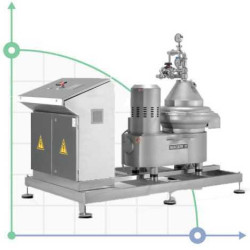

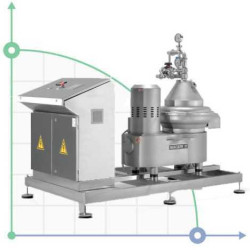

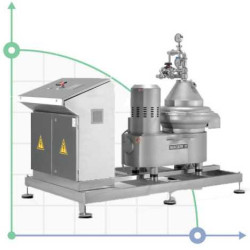

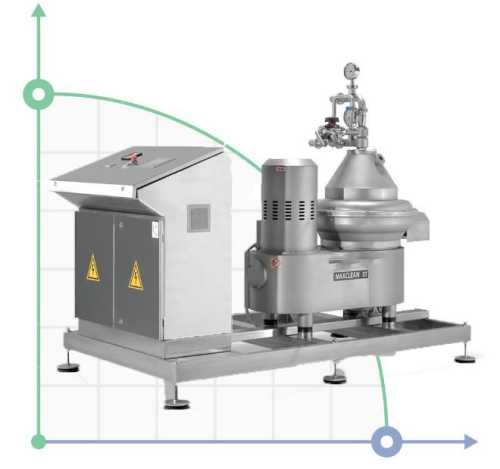

Whey separator MAXCLEAN

Whey separator MAXCLEAN

Milk separator

The most efficient separators in its class, specially designed for dairies of different sizes Separators are designed for clarification of liquid in liquid-solid mixtures or for liquid-liquid separation in liquid-liquid-solid mixtures. The general principle is the continuous and rapid extraction of solid particles from the medium by mechanical separation of the various liquid and solid phases.

Separators MAXCLEAN

Centrifugal Separator for Milk and Whey

The MAXCLEAN separator is a centrifugal separator designed for milk and whey clarification, equipped with a centrifugal pump, automatic partial and full drain functions, suitable for cleaning in place (CIP). The MAXCLEAN separator is supplied as a separate unit mounted on a frame and equipped with its own control cabinet.

Capabilities

The MAXCLEAN separator is a new generation separator specially designed for the dairy industry. While the product is processed under highly hygienic conditions, maximum efficiency is achieved by improving the properties:

- The high rotation speed generates a large centrifugal force due to the densely spaced large diameter trays creating a large separation surface.

- The specially designed feeding tube allows for gentle feeding and dispersal of the product, minimizing shear, air entrapment and foaming.

- Dual valve discharge system: able to discharge quickly and accurately, reducing the loss of milk and its valuable components (fat, protein).

- Two pressure discs, a constant pressure valve and an outlet valve separate the milk with high efficiency.

- Hygienic design - high-quality materials, polished plates, high-quality finishing of surfaces in contact with the product to avoid product deposits.

- Easy Drive: frequency converter for soft start and stop without friction clutch and with the lowest possible energy consumption, PLC for automatic separation and CIP sequencing control, operator panel for setting operating parameters and monitoring alarms.

- High quality cast iron bed plated with stainless steel.

- Assembled and tested design, easy to install and ready to go.

Principle of operation

The product is fed into the drum where it is separated by centrifugal force. Centrifugal force separates milk and solid contaminants based on density. The milk flows through small intermittent discs which allow the separation of smaller solids. The purified milk is extracted from the separator under pressure using a centrifugal pump. By means of the back pressure valve in the outlet pipe, the liquid pressure in the drum can be controlled. Heavy solids accumulate on the outer wall of the drum and are discharged from the separator in partial or full discharges at periodic intervals. Although the dense sediment is discharged during the partial discharge process, the entire volume of the drum is discharged during the full discharge operation. Partial and full unloading frequency can be set via HMI interface with PLC control software.

Standard equipment

- Separator block

- Control panel with PLC and HMI

- VFD motor

- Special mounting device

- Spare parts kits

- Operator's manual

Optional

- Feed pump and valve

- Flow control equipment

- CIP system

Materials

| Drum body | Stainless steel EN 1.4418 |

| Drum cover and piston | Duplex EN1.4462 |

| Plates | AISI 316EN1.4401 |

| Other surfaces in contact with the product | AISI 304EN1.4301 |

| Casing and slurry tank | AISI 304EN1.4301 |

| Separator bed | Cast iron lined with stainless steel |

| Control cabinet | AISI 304EN1.4301 |

| Frame | AISI 304EN1.4301 |

MAXCLEAN 5T

| TECHNICAL DETAILS | |

| Maxclean 5T Separator | |

| Capacity (l/h) | up to 5000 |

| Motor power (kw) | eleven |

| Length x Width x Height (mm) | 1460x1700x1950 |

| Can be used in | Milk purification |

MAXCLEAN 10T

| TECHNICAL DETAILS | |

| Maxclean 10T Separator | |

| Capacity (l/h) | up to 10000 |

| Motor power (kW) | fifteen |

| Length x Width x Height (mm) | 1460x1700x1950 |

| Can be used in | Milk purification |

MAXCLEAN 15T

| TECHNICAL DETAILS | |

| Maxclean 15T Separator | |

| Capacity (l/h) | up to 15000 |

| Motor power (kW) | 18.5 |

| Length x Width x Height (mm) | 1460x1700x1950 |

| Can be used in | Milk purification |

MAXCLEAN 25T

| TECHNICAL DETAILS | |

| Maxclean 25T Separator | |

| Capacity (l/h) | up to 25000 |

| Motor power (kW) | 22 |

| Length x Width x Height (mm) | 1500x2400x2170 |

| Can be used in | Milk purification |

MAXCLEAN 40T

| TECHNICAL DETAILS | |

| Maxclean 40T Separator | |

| Capacity (l/h) | up to 40000 |

| Motor power (kw) | 37-45 |

| Length x Width x Height (mm) | 1810 x 1950 x 2170 |

| Can be used in | Milk purification |