Separators Series D dairy industry

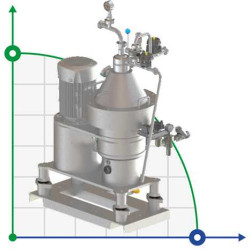

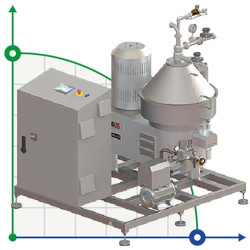

HAUS milk separators are specially designed for the processing of milk and whey. The MAX series separators, with the ability to operate in fully automatic lines, with Cleaning In Place (CIP) system and high quality stainless steel construction, are designed to fully meet the needs of the industry.

HAUS milk separators reduce shear stress and minimize frothing thanks to a specially designed feed tube. Parts of a drum group; smooth surfaces in contact with food are machined with rounded corners and chamfers to avoid blind spots. Due to these design features, the cleaning fluid contacts all points of the separator during cleaning in place (CIP) and ensures effective cleaning. Offers maximum service time with high levels of hygiene and efficiency. The separator is ready to work on the platform, avoiding cable mess. Operating parameters are easily adjusted on the touch panel. Thanks to their robust design, HAUS milk separators are used continuously in many dairy companies.

MAXCLEAN is used to remove organic and inorganic solids/contaminants found in milk and whey. MAXCLEAN BACTERIA separators provide higher product quality by reducing the number of spores in milk and the total number of bacteria before pasteurization.

MAXCREAM separators are designed to quickly and hygienically separate the fatty part of milk from milk, and are also effective in removing contaminants. They are used to separate standard or highly concentrated cream in milk or butter in whey. MAXCREAM and MAXCLEAN separators provide solid emissions with minimal product levels due to high separation efficiency, quality material and an efficient discharge system.

DBA separators are used to concentrate and purify simple milk fat (anhydrous milk fat).

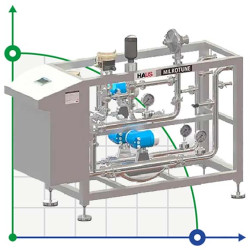

MILKOTUNE, on the other hand, is a specially designed equipment that ensures the standardization of milk by adding the desired amount of cream to the skimmed milk from the separator.

High quality stainless steel construction

Specially designed feed pipe

Suitable for Cleaning-In-Place (CIP)

Fast and efficient unloading system

Hygienic Design

High separation efficiency