Mechanical seals for INOX pumps

Types of CSF Inox Mechanical Seals

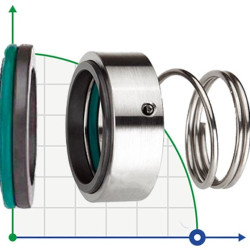

CSF Inox® mechanical seals of types CS, CL-CLC-CV are available in several types and sizes. The most popular are conical spring seals. Special seal variants are also available to best suit your application.

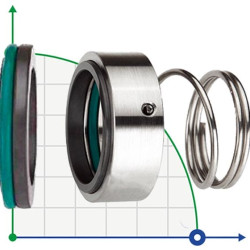

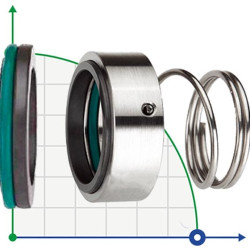

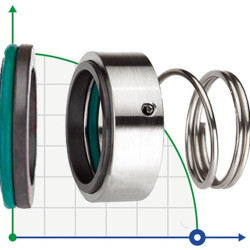

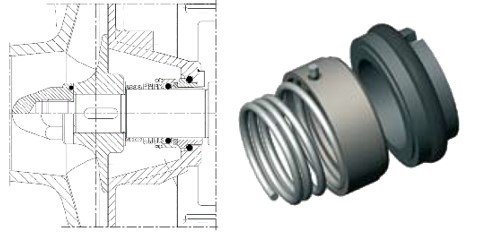

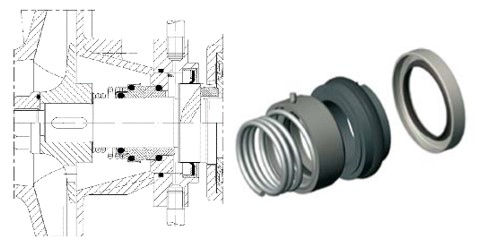

Type T – single mechanical, internal.

By default, the CSF Inox pump is equipped with a single internal mechanical seal of the T series, lubricated by the product itself. The seal is located behind the impeller in a conical chamber.

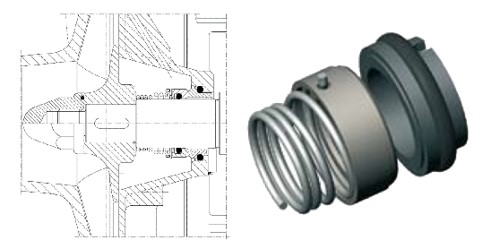

Type W – single mechanical seal with forced liquid circulation.

The internal mechanical seal type W with forced liquid circulation (when pumping hot liquids) is used to reduce operating temperature, remove air and vapor bubbles, and prevent deposit formation on the seal.

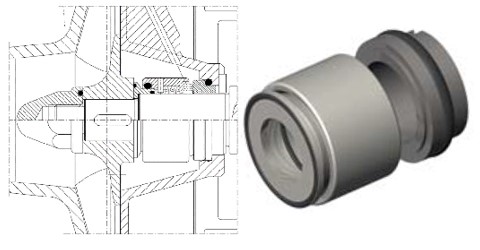

Type WH – single, balanced mechanical seal in sanitary design.

Thanks to its isolated spring, this seal is suitable for viscous and dirty products. It is also easy to clean, which is important for hygienic or pharmaceutical applications. The balanced design with forced circulation of the pumped liquid allows the WH mechanical seal to be used in vacuum applications or with pressure differences.

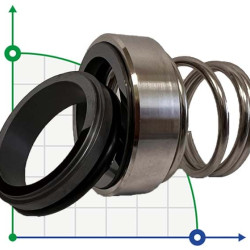

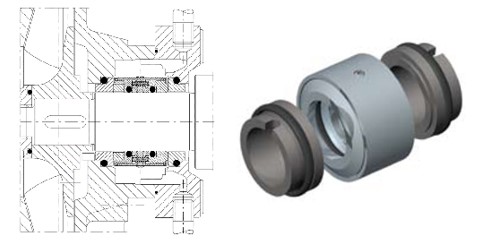

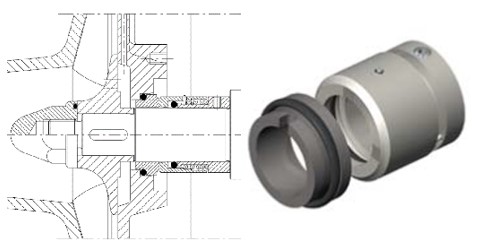

Type Q – compact double mechanical seal, internal.

Double mechanical seal with circulation of cooling liquid. Used for products prone to crystallization, sticking, abrasive or corrosive, and at high temperatures.

Type V – single, internal, with lip seal.

This is a compact flush version with a lip seal, cheaper compared to type Q. The external chamber prevents motor damage and contamination of the environment due to possible leaks from the internal mechanical seal.

Type WHEX – hygienic, external, balanced.

For situations where the mechanical seal must not contact the product, for example for hygiene purposes, to avoid corrosion, or to meet specific technological requirements.

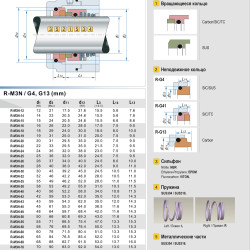

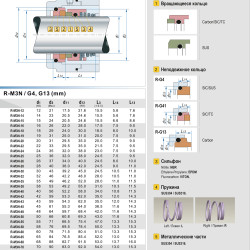

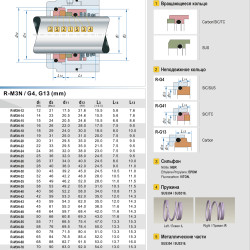

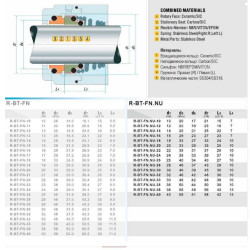

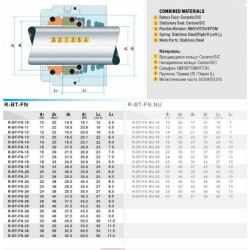

We also offer CSF Inox screw pump seals type M in two installation variants: internally mounted seals, dependent or independent of pump rotation direction, and externally mounted seals. They are available in several sizes and materials.

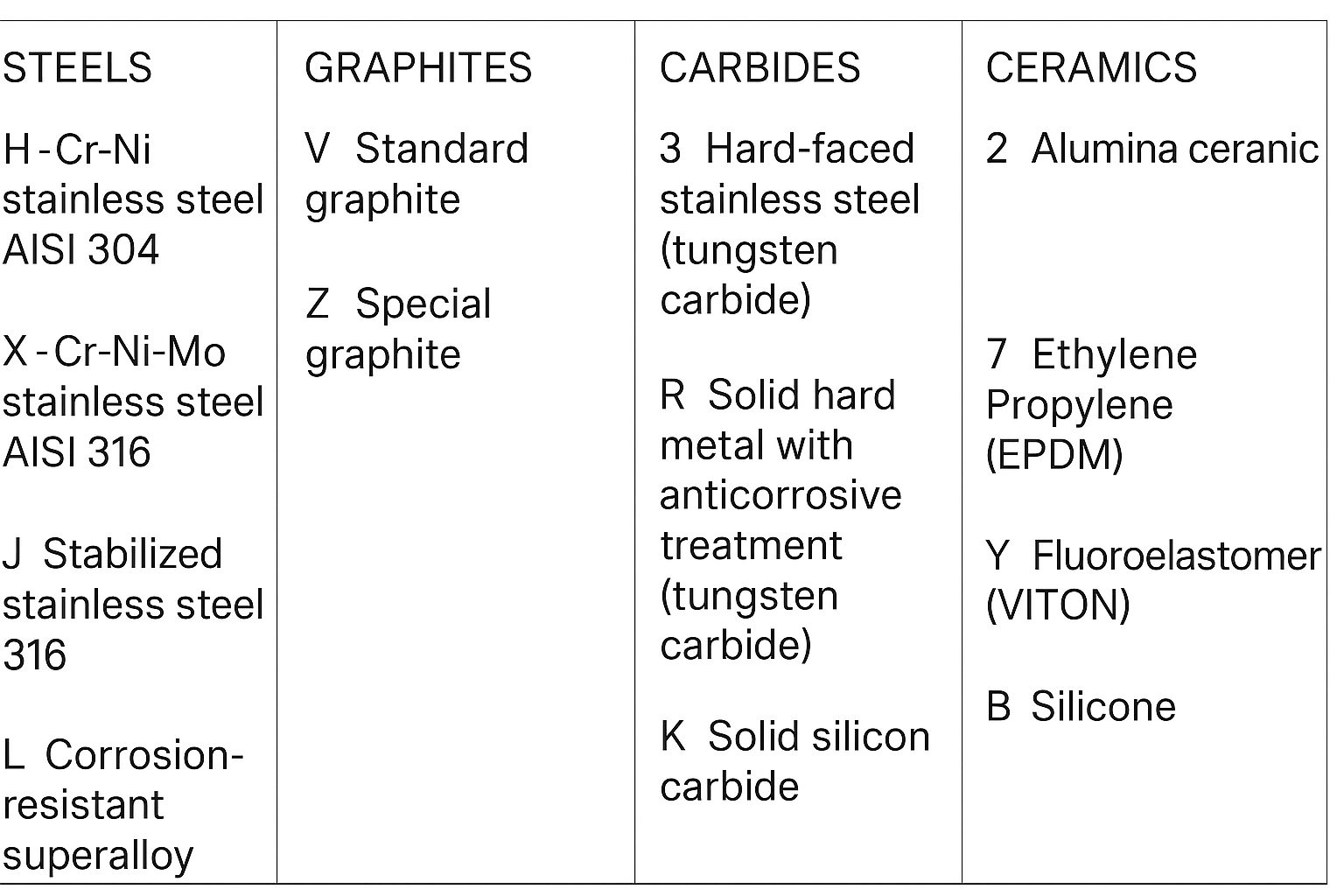

Material codes: