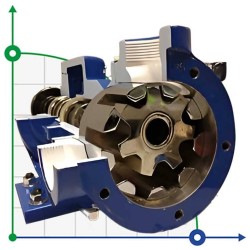

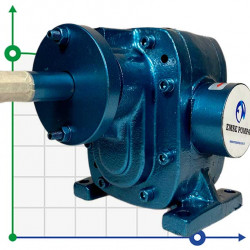

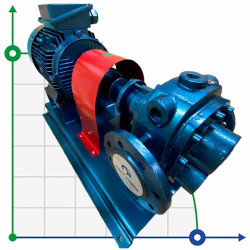

Gear pumps

Gear pumps are rotary-type devices that are additionally equipped with two or more gears in their design. They are located in the working part of the pump and provide better grafting due to their teeth. In such systems, basically one gear wheel acts as the driving impeller and starts the entire system using an electric motor. The parts are grafted together and ensure uninterrupted movement and, accordingly, pumping of liquid. Usually spur gears. In some cases, there may be significantly more gears.

Advantages of gear pumps for liquid pumping

Such pumps are very popular with owners of small households. They fully meet their needs and meet the stated requirements, which allows them to be effectively used for equipping water systems with pumps.

Among the obvious advantages, it is worth highlighting:

- Financial availability and low price compared to analogues;

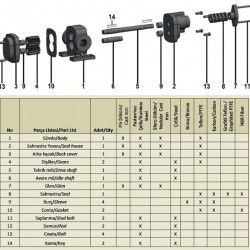

- Simple device design and easy replacement of parts or operation;

- Compact size and light weight of the pump;

- Adaptability and the ability to use in many already developed systems;

- Good power and the ability to work at high speed;

- The ability to ensure uniform water pressure even during long-term work.

In general, gear pumps are ideal for small applications where you need to provide fast water flow without interruptions or performance degradation.

How to use gear pumps correctly

Gear pumps have a simple but specific design. Therefore, you should also use them taking into account the following features. First of all, it is necessary to monitor the wear of gears, seals and valves, since failure of such parts can lead to damage to the entire device. It is not recommended to pump liquids with gear pumps, thick liquids, or liquids with high temperature. It is not allowed for air to appear in the suction part or solid particles to enter. Also, it is better not to increase the pressure in the system. By following these simple recommendations, you can achieve maximum performance of gear pumps and provide the farm with a reliable device for pumping water.