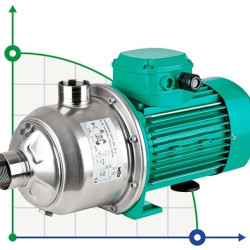

Multistage pumps

CDLF multistage pumps

Multistage pumps of the CDLF seriesdesigned to increase pressure in an existing water supply system. They are high pressure, highly efficient and do not consume much energy.

The impeller guiding the impeller and all parts in contact with the liquid are made of stainless steel by stamping and casting, which means the flow path is smooth and prevents contamination. The shaft and coupling are made of high quality carbide and have a mechanical seal that lasts long and does not leak. All features of the pump ensure quiet, uniform operation. The pump has a compact design, easy to transport and install, and environmentally friendly. CDLF pumps can be widely used for domestic and industrial water supply. Multistage pumps are made of stainless steel. Reliable, quiet and easy to operate pumps are used in municipal, industrial and agricultural facilities. For example, in fire extinguishing systems, booster systems, water treatment, irrigation, hot and cold water supply in heating, cooling and air conditioning systems, especially for feeding boilers due to the reliable design of the pump.

performance

Multistage pumps

Applications:

- Water supply: water filtration and its supply through water supply networks, increasing pressure in the water supply and in multi-storey buildings.

- In industry: process water, flushing system, pressure flushing system, fire extinguishing system.

- Industrial water supply: cooling and air conditioning system, water supply to the boiler, condensing system, production plants, work with acids and alkalis.

- Water treatment: ultrafiltration system, reverse osmosis system, distillation system, separation, use in swimming pools.

- Irrigation: irrigation of agricultural land, sprinkler irrigation, drip irrigation, etc.

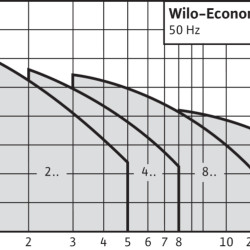

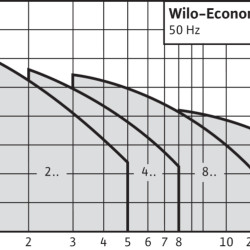

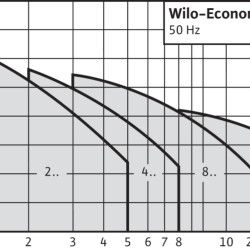

Performance charts for CDLF pumps

materials

| No. p/n |

Name | material | AISI/ASTM |

| one | electric motor | - | Standard/Ex |

| 2 | Frame | cast iron | ASTM25B |

| 3 | mechanical seal | stainless steel | AISI304/316L |

| four | Water outlet impeller | stainless steel | AISI304 /316L |

| 5 | pumps the impeller | stainless steel | AISI304 /316L |

| 6 | supporting impeller | stainless steel | AISI304 /316L |

| 7 | Device for supplying fluid under pressure | stainless steel | AISI304/316L |

| eight | Pump suction and discharge | stainless steel | AISI304/316L |

| 9 | support frame | cast iron | ASTM25B |

| ten | Sleeve on the shaft | durable alloy | YG8 |

| eleven | Working wheel | stainless steel | AISI304 /316L |

| 12 | Shaft | stainless steel | AISI316 |

| 13 | Decoupling impeller coupling | stainless steel | AISI304 /316L |

| fourteen | Pump casing | stainless steel | AISI304/316L |

| fifteen | Coupling | carbon steel | - |

| 16 | seals | FPM /VITON | - |

Specifications for CDLF pumps

| Model | 50 Hz CDLF 2 | 50 Hz CDLF4 | 50 Hz CDLF 8 | 50 Hz CDLF 16 |

| Nominal capacity (m³/year) | 2 | four | eight | 16 |

| capacity range(m³/year) | 1-3.5 | 1.5-8 | 6-12 | 8-22 |

| rotational speed (r/hv) | 2900 | 2900 | 2900 | 2900 |

| motor power (kW) | 0.37-3 | 0.37-4 | 0.75-7.5 | 2.5-15 |

| Head (m) | 15-195 | 16-176 | 12-196 | 22-189 |

| temperature range (°C) | -15°C + 120°С |

-15°C + 120°С |

-15°C + 120°С |

-15°C + 120°С |

| Maximum Efficiency (%) | 46 | 59 | 64 | 71 |

| Max pressure (bar) | 23 | 22 | 22 | 22 |

| external temperature | up to +40°C | up to +40°C | up to +40°C | up to +40°C |