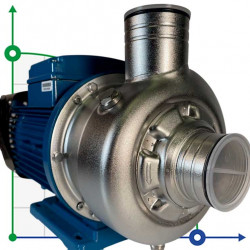

Pumps with open and closed impeller DWO

Open impeller pumps DWO

DWO Centrifugal Pumps for Dirty Liquids

Description:

DWO open impeller pumps are used in industrial metal surface treatment, cooling systems, canteen dishwashers, industrial laundries, vegetables, fruits and other food products.

Centrifugal pumps with an open impeller of the DWO series are designed for pumping both clean and rather polluted water, the size of suspended solids up to 19 mm.

AISI 304 stainless steel open impeller pump.

Pump DWO Ebara

DWO pump impeller

Design

- AISI 304 stainless steel pump housing;

- Aluminum motor housing;

- AISI 303 stainless steel motor shaft;

- Shaft seal: ceramic/charcoal/NBR;

- AISI 304 stainless steel impeller.

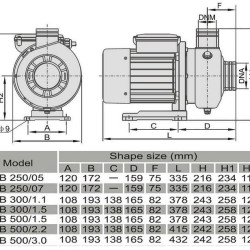

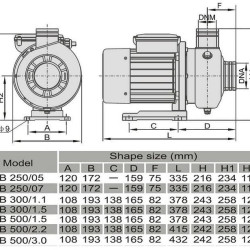

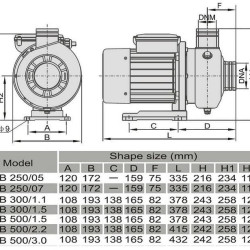

Technical data of the pump part:

- maximum pressure: 8 bar;

- maximum water temperature: 80°C;

- inlet: 2";

- outlet: 2";

- maximum through hole: 19 mm.

Engine technical data

- insulation class: F;

- protection: IP 55;

- voltage: single-phase version 230V ±10%, three-phase version 400V ±10%;

- number of revolutions: 3000 rpm;

- built-in thermal protection for single-phase version.

Application

- water treatment;

- industrial sinks;

- painting equipment;

- heating and air conditioning;

- pumping contaminated liquids.

Operating characteristics

Performance table / DWO open impeller pumps

|

Type of |

Power |

Current, A |

Q=Performance | |||||||||||

| ~1 | ~3 | kW | ~1 |

~3 |

l/min | 100 | 200 | 300 | 400 | 550 | 750 | 950 | 1100 | |

| 230V | 230/400V | 230V | 230V | 400V | m³/hour | 6 | 12 | eighteen | 24 | 33 | 42 | 57 | 66 | |

| H=Head | ||||||||||||||

| - | DWO 120D | 0.9 | eleven | ten | 9 | - | - | - | - | - | ||||

| DWO 150M | DWO 150 | 1.1 | 6.8 | 4.4 | 2.5 | 9.5 | 8.9 | 7.9 | 6.9 | 5.1 | - | - | - | |

| DWO 200M | DWO 200 | 1.5 | 9 | 6.1 | 3.5 | 12.7 | 12.3 | 11.5 | 10.5 | 8.6 | 5.8 | - | - | |

| - | DWO 300 | 2.2 | - | 8.3 | 4.8 | fifteen | 14.5 | 13.8 | 12.9 | 11.7 | 9.7 | 7.5 | - | |

| - | DWO 400 | 3 | - | eleven | 6.4 | 17.5 | 16.9 | 16.3 | 15.6 | 14.3 | 12.4 | 9.8 | 7, | |

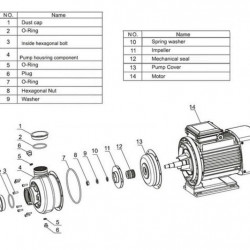

Design

|

No. |

PART NAME |

MATERIAL |

AMOUNT |

No. |

PART NAME |

MATERIAL |

PCS. |

|

one |

Frame |

AISI 304 |

one |

25 |

Filler plug |

AISI 303 |

one |

|

3 |

engine brace |

Aluminum |

one |

26 |

Sealing ring |

NBR |

one |

|

four |

Outer casing |

AISI 304 |

one |

thirty |

Gland protection |

AISI 304 |

one |

|

6 |

Shaft |

AISI 304 |

one |

32 |

Key |

AISI 304 |

one |

|

7 |

Working wheel |

AISI 304 |

one |

34 |

screw |

AISI 304 |

one |

|

eleven |

Oil seal [3] |

Ceramic/Graphite/NBR |

one |

42 |

Engine caliper |

Aluminum |

one |

|

12 |

Motor frame with stator |

- |

one |

fifty |

pad |

- |

one |

|

13 |

engine cover |

Aluminum |

one |

52 |

Terminal box [1] |

Polypropylene |

one |

|

fourteen |

Fan |

Polypropylene |

one |

56 |

gasket class. boxes |

NBR |

one |

|

fifteen |

Fan cover |

Galvanized steel Fe P04 |

one |

75 |

Washer |

AISI 304 |

one |

|

16 |

Terminal box |

- |

one |

76 |

Washer |

AISI 304 |

one |

|

17 |

Terminal box cover [2] |

Aluminum |

one |

77 |

Sealing ring |

NBR |

one |

|

eighteen |

Protective ring |

NBR |

one |

78 |

Sealing ring |

NBR |

one |

|

19 |

pump bearing |

- |

one |

90 |

Cover gasket [1] |

NBR |

one |

|

twenty |

Fan bearing |

- |

one |

92 |

Cuff |

- |

one |

|

21 |

adjusting ring |

Steel C70 |

one |

93 |

Cuff |

- |

one |

|

22 |

Connecting rod |

Galvanized steel Fe 42 |

four |

110 |

Fuse [1] |

- |

one |

| 23 | Capacitor [1] | - | one | 200 | Screw | Stainless steel A2 UNI7323 | 6 |

| 24 | Filler plug | AISI 303 | one |