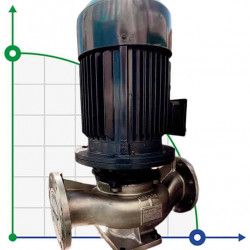

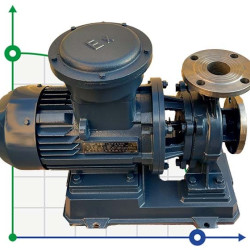

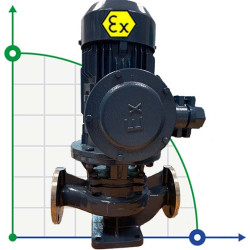

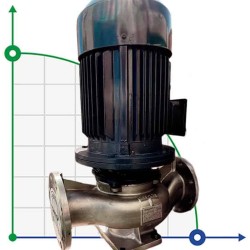

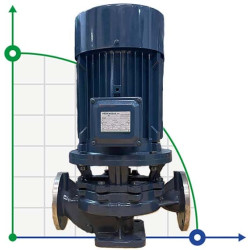

Stainless Steel Dry Rotor Pumps

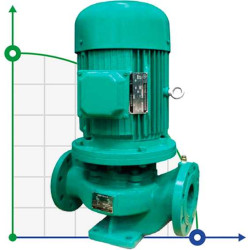

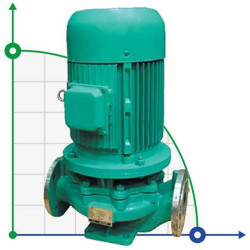

IHG dry rotor pumps are vertical single-stage centrifugal chemical pumps, in-line execution, for pumping liquids in the oil, chemical, metallurgy, electrical, paper industries, as well as the medical industry with a pumped medium temperature of -20°C ~ +120°C, in standard version.

The main parts of the pump housing, as well as the impeller, are made of high quality stainless steel, which allows pumping aggressive liquids. IHG pumps are also available in explosion-proof versions.

Characteristic:

- The IHG series dry rotor pump body is made of stainless steel, approved for use in the food and chemical industries;

- Dry Rotor Pump Series IHG have a vertical design. Their suction and discharge nozzles are located on the same axis, which allows them to be installed directly on the pipeline (in-line). Pumps have compact overall dimensions, do not take up much space and can be installed outdoors (under a canopy);

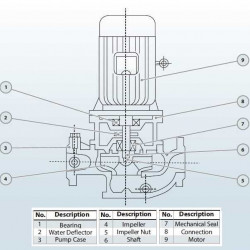

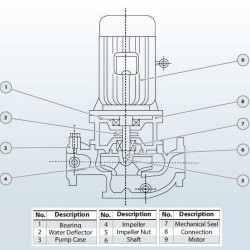

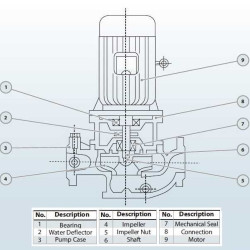

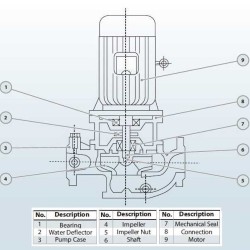

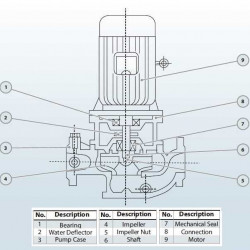

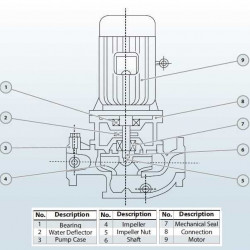

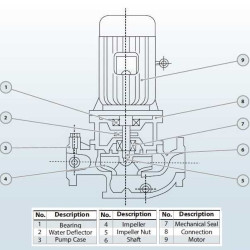

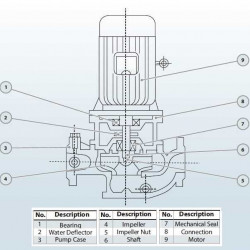

- The IHG dry rotor pump impeller is located directly on the motor shaft, so that they run quietly without creating high vibration, and the pump casing is connected to the motor in such a way that the thrust pressure can be significantly reduced during pump operation;

- To seal the pump shaft, a special chemically resistant mechanical seal is used, due to which the service life of the pumps is significantly increased;

- The pumps are easy to install, service and repair, and there is no need to dismantle them, since it is enough to unscrew the bolts that attach the motor to the housing and pull out the rotor.

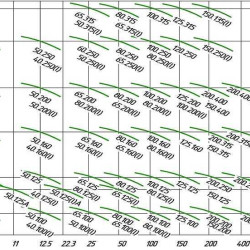

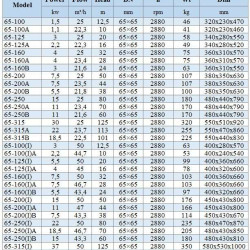

IHG Glanded Stainless Steel Pump Range

| Model | Consumption (m3/hour) |

pressure (m) |

Power (kW) |

turnovers (rpm) |

Diameter (mm) |

NPSN (mm) |

efficiency |

The weight (kg) |

| 50-125A | eleven | 16 | 1.1 | 2900 | fifty | 2.3 | 57 | 38 |

| 50-125(I)A | 22.3 | 16 | 2.2 | fifty | 2.5 | 66 | 48 | |

| 50-200(I)A | 23.5 | 44 | 5.5 | fifty | 2.5 | 57 | 107 | |

| 65-125 | 25 | twenty | 3 | 65 | 2.5 | 68 | 58 | |

| 65-160 | 25 | 32 | four | 65 | 2.5 | 63 | 75 | |

| 65-200 | 25 | fifty | 7.5 | 65 | 2.5 | 58 | 107 | |

| 65-250 | 25 | 80 | fifteen | 65 | 2.5 | fifty | 180 | |

| 80-125 | fifty | twenty | 5.5 | 80 | 3.0 | 72.5 | 99 | |

| 80-100(I) | 100 | 12.5 | 5.5 | 80 | 4.5 | 76 | 108 | |

| 80-125(I) | 100 | twenty | eleven | 80 | 4.5 | 76 | 163 | |

| 80-160 | fifty | 32 | 7.5 | 80 | 3.0 | 71 | 105 | |

| 80-200 | fifty | fifty | fifteen | 80 | 3.0 | 67 | 175 | |

| 100-100A | 89 | ten | four | 100 | 4.5 | 74 | 91 | |

| 100-160 | 100 | 32 | fifteen | 100 | 4.5 | 76 | 191 | |

| 100-200 | 100 | fifty | 22 | 100 | 4.0 | 74 | 245 | |

| 100-200(I) | 160 | fifty | 37 | 100 | 5.2 | 79 | 402 | |

| 200-315 | 200 | 32 | thirty | 1450 | 200 | 3.5 | 78 | 417 |

| 200-400A | 187 | 44 | 37 | 200 | 3.5 | 74 | 462 | |

| 200-250(I)A | 358 | 16 | twenty | 200 | 4.0 | 73 | 405 | |

| 200-315(I) | 400 | 32 | 55 | 200 | 4.0 | 80 | 675 | |

| 200-315(I)A | 374 | 28 | 45 | 200 | 4.0 | 79 | 560 | |

| 200-315(I)B | 346 | 24 | 37 | 200 | 4.0 | 78 | 535 |

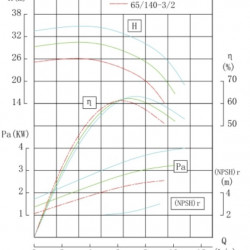

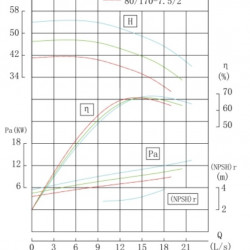

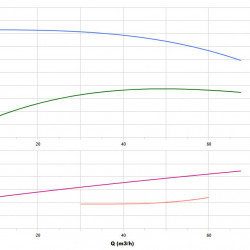

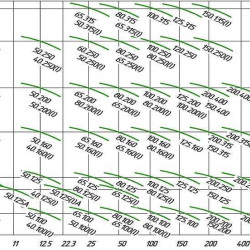

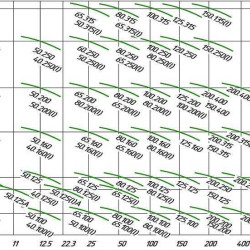

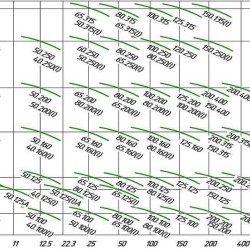

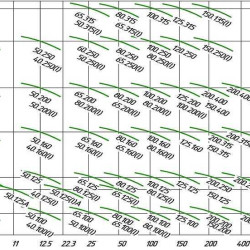

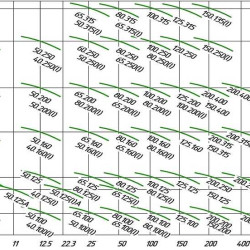

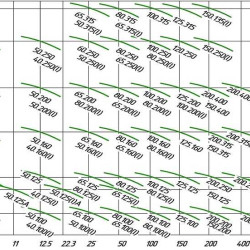

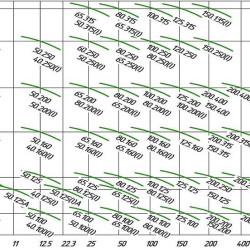

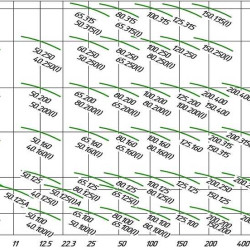

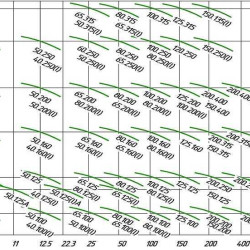

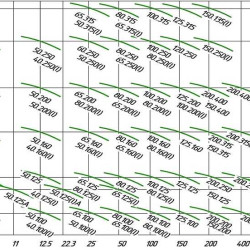

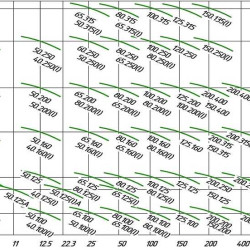

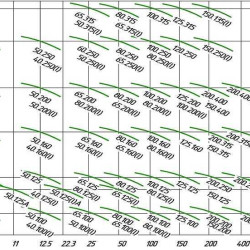

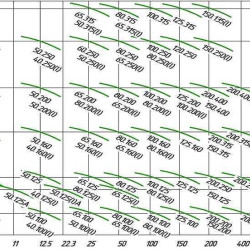

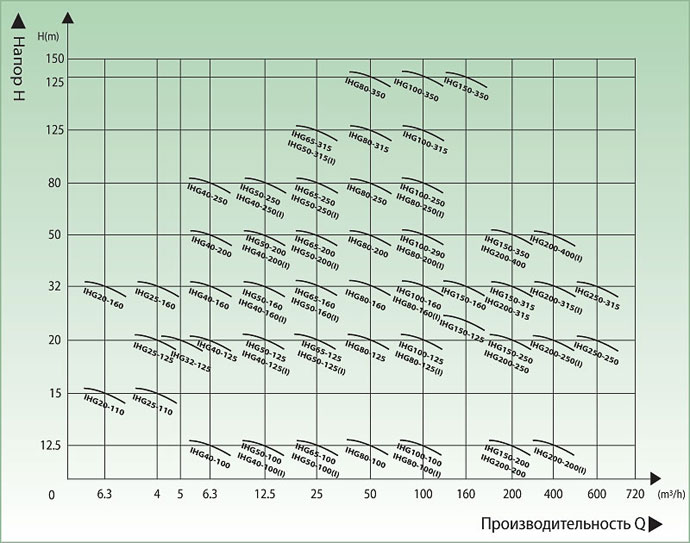

IHG Series Dry Rotor Pump Performance Charts

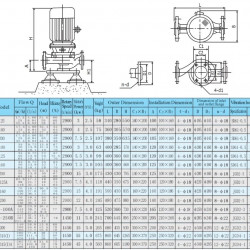

Specifications

| Pump data |

materials | ||

|

Step no. pressure |

PIN 16 |

Frame Shaft Working wheel slip ends. seal casing |

Stainless steel |

End seal for IHG pump

Pump Diagram

Installation methods

Mounting dimensions and fittings

Installation of equipment

Parts to be replaced when worn