Check valves

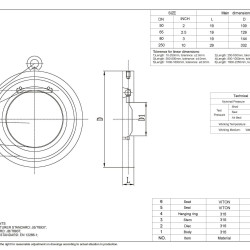

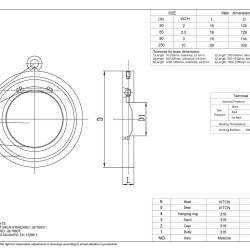

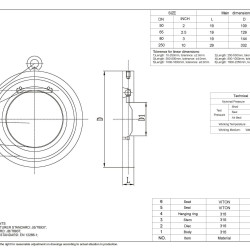

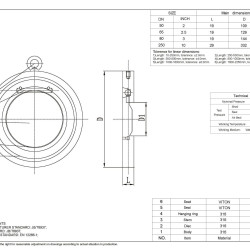

The main types of check valves are actually check valves and check valves, their main difference is in the design of the shutter (an element that blocks the flow of the medium by sitting in the saddle), for the first it is made in the form of a spool, for the second it is in the form of a round disk, which is often called a clasp.

Check valves are usually installed in horizontal sections of pipelines, and gates - in both horizontal and vertical sections. In the direction of the flow of the working medium, check valves are mainly made through passage (the direction of flow in them does not change), but there are also angular ones (the direction of flow changes by 90°), and check valves are only through passage.

In the absence of medium flow through the armature, the spool in the check valve or the flap in the check valve under the action of its own weight or additional devices (for example, springs) are in the “closed” position, that is, the valve is in the seat of the body. When a flow occurs, the shutter, under the action of its energy, opens the passage through the saddle. It is clear that in order for the flow of the medium to change its direction to the opposite one, it must stop. At this point, the flow rate becomes zero, the valve returns to its original closed position, and the pressure from the back side presses the spool or flap, preventing the back flow of the medium. Thus, the operation of the check valve occurs under the action of the medium itself and is fully automatic.