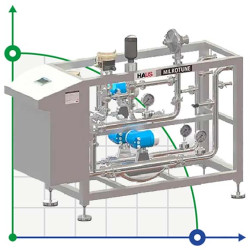

MILKOTUNE series automatic milk processing installation

MILKOTUNE is an automatic milk processing unit designed for milk standardization and used immediately after the cream separator. It was developed by HAUS for the dairy industry, especially for adjusting the amount of fat in milk and cream. The goal of the milk standardization process is to obtain full-fat milk in accordance with market and legal regulations. MILKOTUNE determines how much cream to add to the skimmed milk to achieve the desired fat content in the milk, and then doses the required amount of cream with high precision and ensures high savings in the long run. It can also adjust the amount of fat in the cream and keep it constant.

Thanks to the automatic flow equipment at MILKOTUNE, fluctuations in flow are balanced, allowing the separator to operate stably. Despite the quality of raw milk and fluctuations in separation efficiency, it has a physical reading equipment that allows you to measure the amount and flow density of skim milk and cream with high accuracy, know the real amounts of fat and achieve standardization. The flow control procedure recognizes the times when the separator releases solids, which prevents fat calculations from being disturbed and ensures accurate measurement.

MILKOTUNE operating mode settings can be selected for several operating purposes.

- Milk Standardization Mode: Used to obtain milk with the desired amount of fat by adding cream to skimmed milk.

- Fat Standardization Mode: Used to control the amount of fat in the cream leaving the separator.

- Separation Mode Only: Used to simply turn off the machine and operate with only the separator.

- CIP mode: Used with automatic valve timing for efficient cleaning and high hygiene.

The operating mode can be easily selected using the touch panel, parameters, alarms and automatic CIP sequencing can be set. The physical data measured on the equipment are automatically processed by special software and a detailed database and converted into the amount of cream and milk fat.

PRINCIPLE OF OPERATION

The connections with skimmed milk and cream leaving the cream separator are connected to a standardization unit from two separate lines. The equipment measures the amount and density of the flow, and the values are transmitted to the PLC, which can calculate the actual fat content of skimmed milk and cream. Standardization can add the amount of cream needed to achieve the desired amount of fat in the milk. The device can regulate within a certain range the amount of fat (concentration) in the cream produced by the separator, thanks to the automatic control valve controlled by the PLC. Other automatic valves compensate for fluctuations in flow, ensuring stable operation of the separator. The required amount of fat can be easily adjusted by the operator along with other optimization parameters on the PLC screen.

Many Operating Modes

High accuracy

Excellent Software

Suitable for Cleaning-In-Place (CIP)

MILKOTUNE

| SPECIFICATIONS | |

| DIMENSIONS (Length * Width, Height) | 1920*670, 1430mm |

| THE WEIGHT | 260 kg |

*HAUS reserves the right to make changes to the specifications shown here without prior notice to the customer.